Efficiency meets precision: clamping and automation solutions for any production environment

The future of metalworking is flexible, precise and automated. At EMO Hannover 2025, SCHUNK will show how flexible fixtures, modular automation concepts and global engineering expertise help companies make their processes efficient and future-proof.

How can companies future-proof their processes in times of global uncertainty, increasing competitive and cost pressures and skilled labor shortages. This question concerns the metalworking industry more than ever. EMO Hannover, the world's leading trade fair for production technology, offers answers. At SCHUNK, visitors can expect practice-oriented production modules that make the handling and processing of parts in machines easier, more flexible and more efficient.

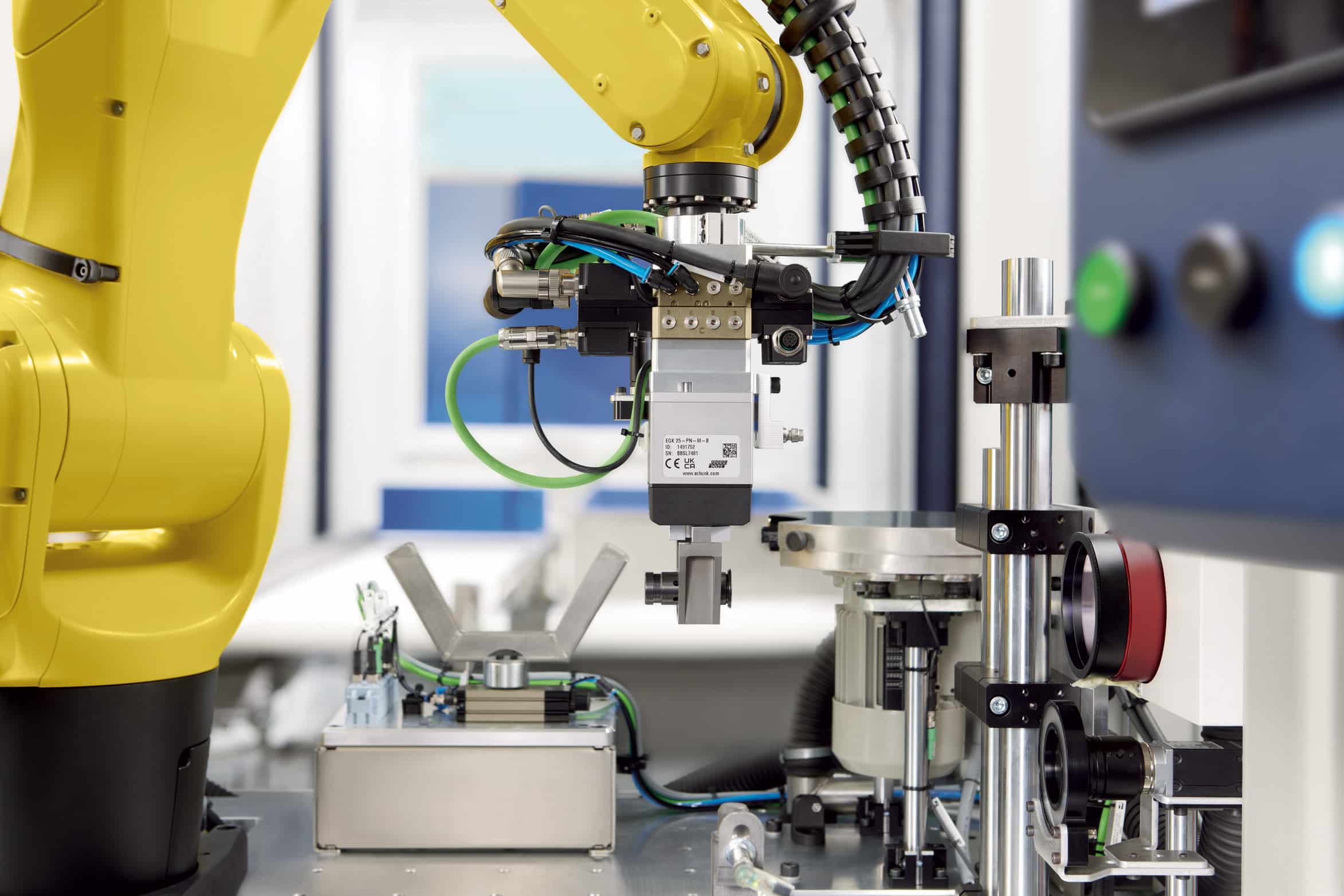

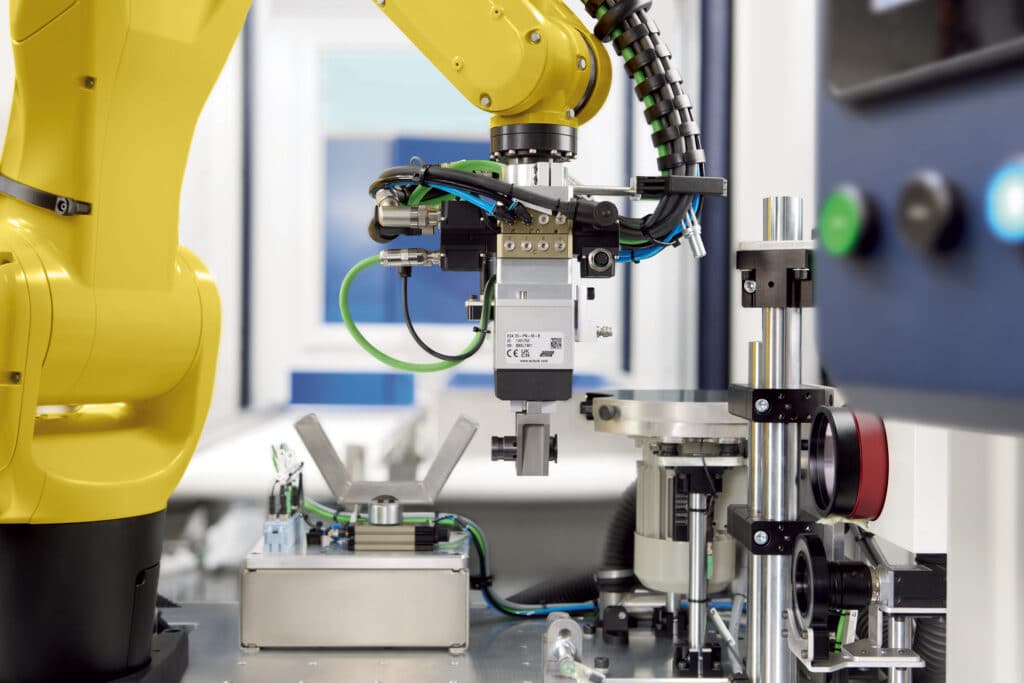

Efficient automation of machine tools

Automated loading and unloading are important factors in increasing productivity and efficiency in the production process. But which automation solution suits which production process? The application specialist provides advice and offers a wide range of forms of automation tailored precisely to the requirements of batch sizes, workpieces and production processes. The focus is not only on delivering the right components to users, but also on supporting them from the start with sound expertise and the right steps.

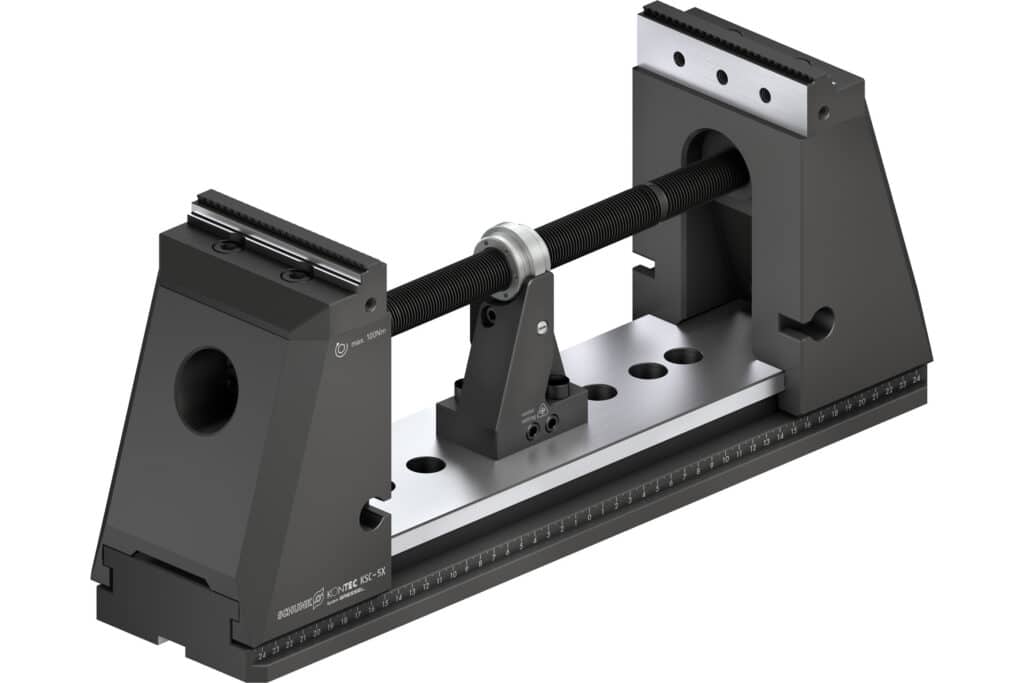

New clamping solutions for versatile applications

In addition to automation, SCHUNK also offers all the building blocks for versatile and quickly adjustable workpiece clamping in the machine. For the machining of complex workpieces or small series, the company presents new clamping solutions tailored to the requirements of flexible production environments.

With the KONTEC KSC-5X SCHUNK expands its family of 5-axis clamps with a powerful centric clamp. This has been specially developed for demanding machining operations. The higher base jaws allow - in combination with a unique range of system and attachment jaws, the clamping of complex workpieces with optimum accessibility. Thanks to a quick-change system, the clamp can be quickly and easily adapted to new clamping tasks. Due to the integrated zero-point interface, it fits seamlessly into the comprehensive SCHUNK clamping technology modular system, which offers versatile combination options for highly efficient workpiece clamping.

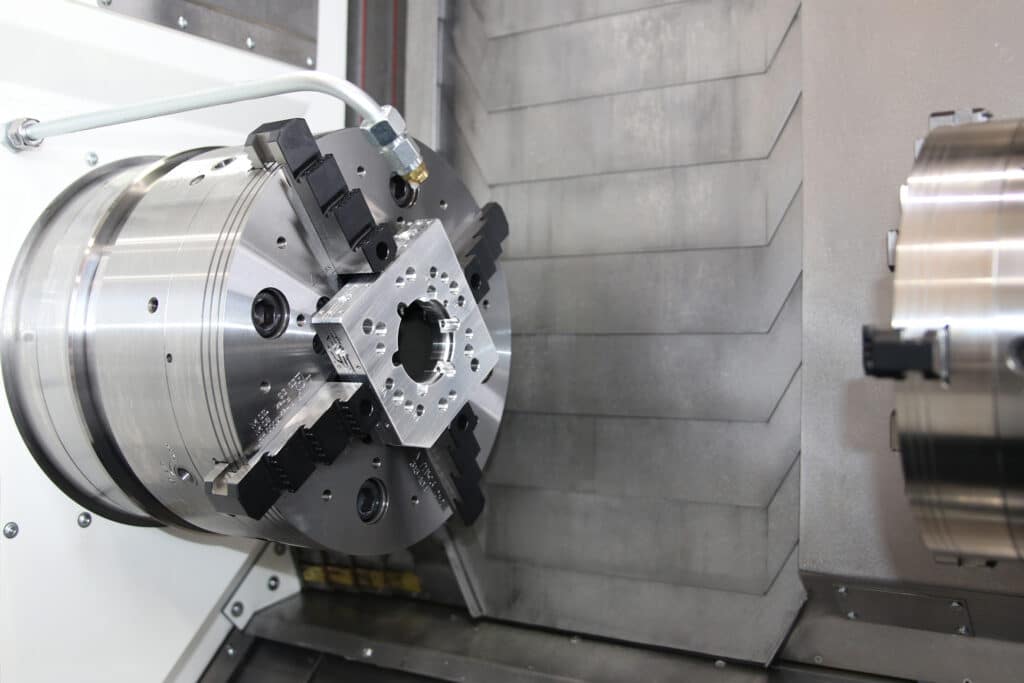

SCHUNK is also focusing on maximum flexibility for its chucks. After the hand-operated chucks, a 2+2 compensation chuck is now also available for power-operated chucks. The new ROTA THW3 2+2 enables centric compensation clamping of workpieces with different geometries - from round and cubic parts to irregularly shaped parts - thanks to an innovative drive concept. With patented sealing, permanent lubrication and quick-change jaw system, this chuck combines low-maintenance operation with short changeover times and consistently high clamping forces.

Tailor-made with SCHUNK Engineering

Every production environment is unique - and standard solutions are not always the best choice. SCHUNK supports users with a structured process for developing customized solutions. From the precise determination of requirements to design, production and integration: SCHUNK accompanies its customers through the entire process. This creates solutions that perfectly match the specific production requirements in various sectors. Examples include customized hydraulic tensioning elements for turbine rotors in the aerospace industry, validated and optimized with digital simulations.

Standardized total solution

Small and medium-sized enterprises in particular need practical, quickly implementable solutions. For this purpose, SCHUNK introduces the new modular GROW automation cells. These turnkey, CE-certified total solutions are intuitive to use, flexibly customizable and designed to automate production processes quickly and efficiently. Whether it is laser marking or part sorting - with GROW, companies can optimize production without specialist prior knowledge, while benefiting from high reliability and scalability.

Data-driven process monitoring in real time

With the increasing automation and digitization of machine tools, intelligent process monitoring is increasingly coming into focus. The electric and sensory clamping systems from SCHUNK enable real-time monitoring of critical process conditions, such as the condition of the clamping elements, the workpiece or tool vibrations. They thus offer greater safety, complete transparency and easy integration into existing machine controls - an essential building block for the production of the future. An absolute highlight are the battery-powered clamping elements, which are integrated wirelessly, for example via radio with common measuring systems or via IO-Link Wireless. Visitors can experience these technologies live at the SCHUNK booth.

Visit SCHUNK at the EMO: Hall 3, Booth I26

schunk.com

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met SCHUNK.

Contact opnemen

Contact opnemen