Do not bend or crack: TUBUS dampers in helicopter transport

Landing a helicopter safely is already no easy task. However, it is even more difficult to transport the hazard as air cargo to another country without damage. For this reason, special air transport guards from SMJ Sondermaschinenbau GmbH were equipped with integrated damping elements from ACE Stoßdämfper GmbH.

When high-quality equipment for rescue operations has to be transported to crisis regions, the challenge is even greater when there is limited space for protection. Such is the case with a transport aircraft for which SMJ Sondermaschinenbau GmbH developed a sophisticated fastening system. The objects to be transported are helicopters that are to be carried in the hold of a cargo aircraft with disassembled rotor blades. And the dimensions of the hold are small: the hold is only slightly larger than the helicopter. To protect the aircraft and the helicopter, a landing protection system was produced in close cooperation with the client. Here, special systems that distribute the load over the helicopter are especially important. Extensive calculations were made to ensure that the loads would be distributed via structural points at the central rotor head and on the cabin floor. In addition to secure attachment, overloads also had to be prevented. Turbulence, rapid course changes and maneuvering during takeoff and landing release considerable forces. Because helicopters are relatively light and the construction fragile, it is not enough to use only chains and straps. Especially since the forces acting on the helicopter during flight can be more than four times its own weight. And that's already more than 3 tons without the rotor blades. To prevent damage, perfect protection is needed. This is why SMJ Sondermaschinenbau worked closely with ACE Stoßdämpfer GmbH.

Customized TUBUS damper as key to safe transport

Determining the right type of structural damper required an exact calculation. For this purpose, the necessary energy absorption was determined. Account was taken of the fact that the landing gear springs along to a certain extent to absorb the impact in the event of a hard landing. However, this is not sufficient to prevent damage in the event of a hard landing or during transport. For example, when a load of 10,000 N acts vertically on the helicopter, the landing gear deforms by 30 mm. The greater the load, the greater the deformation. Based on these values, the two selected TUBUS safety dampers had to have specific force-braking characteristics.

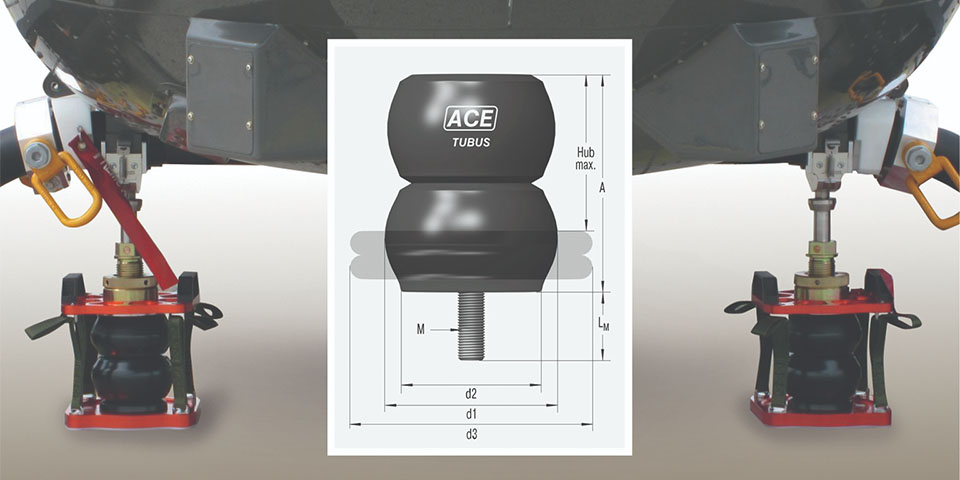

The dampers had to have a certain shape because they had to fit into the construction of SMJ's complete damping system. ACE therefore made customer-specific models based on these principles. Because the safety dampers had to be tested before delivery as proof of these characteristics, different loads were used in tests during development. The specially adapted TUBUS safety dampers allow a further 124 kN of additional energy to be absorbed and thus prevent damage to the helicopter, for example, during a hard landing.

TC-S series specially adapted TUBUS dampers were originally developed for use in crane installations and meet the international industry standards of Occupational Safety and Health Administration (OSHA) and Crane Manufacturers Association of America, Inc (CMAA). The TC-S models are characterized by a so-called dual concept of two damping structure bodies connected together in a single machine part, achieving the required spring rate for crane installations. ACE modified the diameter for the application described above and equipped each custom-made TUBUS with an extra-long stroke length of 146 mm. The first air transports went off to the complete satisfaction of all concerned.