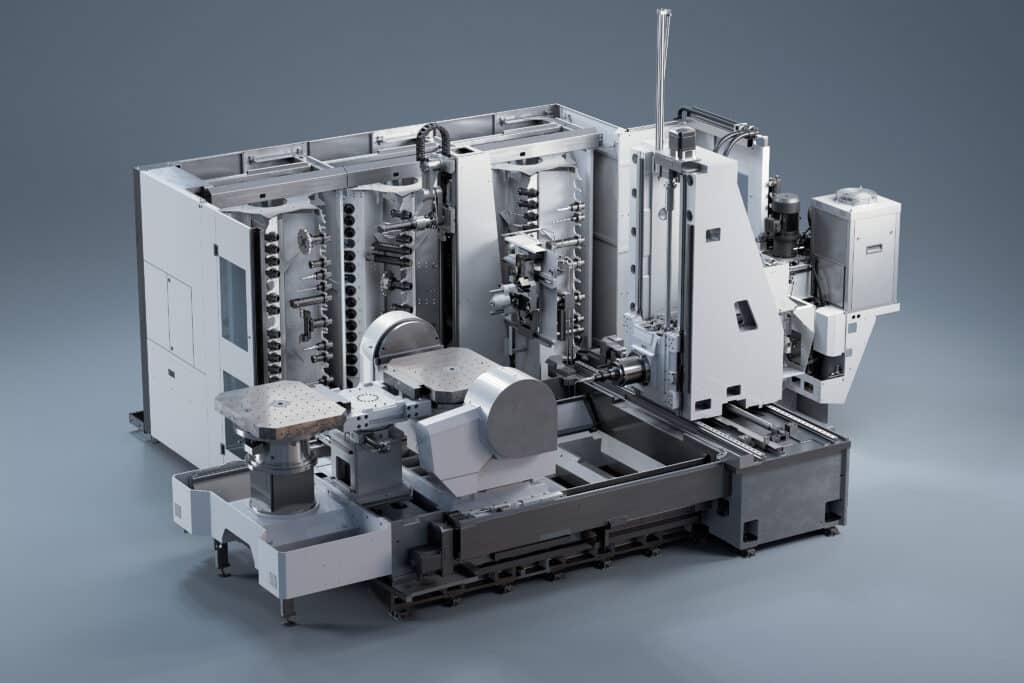

Complete machining of large parts in a compact machining center

Starrag presents three new Heckert 5-axis machines The five-axis Heckert X compact series is complete: in addition to the Heckert X50, which has been available since April 2022, Starrag launched the larger Heckert X70, X80 and X90 versions in April 2025. They replace the successful products HEC 630 X5 and HEC 800 X5 and expand their familiar fields of application: the Heckert X90 enables the machining of larger workpieces.

The new Heckert X70 will be on display at EMO 2025 in Hanover: at the Starrag booth in Hall 12, C93. With pallet dimensions of 630 x 800 mm (Heckert X70) and 800 x 1000 mm (Heckert X80 and X90), the new 5-axis horizontal machining centers are suitable for the complete machining of large components that can be quite heavy. This is because the load weight of the "new" ones ranges from 1,000 kg (Heckert X70) to 2,000 kg in the case of the Heckert X90. The focus is therefore on five-axis heavy machining of gear and cylinder heads, shafts, valve and pump housings, planetary gear carriers and machine components such as pallets, spindle boxes and spindle frames. The special feature of the new machining centers is the smaller space required due to their compact design.

The Heckert X70, for example, requires as much as 18 percent less footprint than its predecessor, the Heckert HEC 630 X5. The other X-Series models also boast similar space savings. Despite the compactness, the user does not have to compromise on the workpiece side. The work area and interference circuit have remained the same, as have the allowable workpiece weight and height. Moreover, turning as a technology is an integral part of the machine concept and can be optionally configured. Thanks to specially developed modules and software modules, classic and complex turning operations can be performed with the incomparable productivity of a machining center. The possibilities for setting up the machine are advantageous compared to a lathe. Clamping is not only done vertically, but thanks to the pallet changer also parallel to the production time. On the tool side, all versions of the large tool magazines can be used, and in the working area, turning diameters of up to 1,400 mm are possible (Heckert X90).

Starrag has continued to implement the typical Heckert features: the machines are robust, powerful, fast and, over the years, exceptionally precise and reliable. Like all new compact machining centers from Chemnitz, the new Heckert X70, X80 and X90 are based on a compact, low-vibration machine bed made of gray cast iron. Together with the thermosymmetrically designed stand, it ensures a very high level of basic mechanical accuracy, to which, among other things, scraped guides also contribute. Thus, the software only has to compensate for the "icing on the cake." The new Heckert X70, X80 and X90 are based on the similar machine sizes of the four-axis Heckert H series. Instead of the NC turntable installed there, the X-series models include a robust turntable - an in-house development also produced at the Starrag plant in Chemnitz. The slewing unit not only has two holders of the same size, but is also thermally stable. This means that the machines are capable of fully machining demanding components on five sides in a very dynamic way. The developers have paid particular attention to the compatibility of the pallets of the new Heckert X70, X80 and X90. They are interchangeable with those of the H series. The pallets of the older Heckert HEC 630 / 800 X5 machines can also be used on the new X models. Another future-oriented point: all machines in the five-axis compact series are equipped with the latest SINUMERIK ONE control, new hardware and high-speed sensors. They are also easier to automate than their predecessors. An expanded 13-channel fixture hydraulics and optimized standard interfaces to pallet storage systems and robotic cells contribute to this.