Coatings: from zero to one hundred

In 2004, the go-ahead for in-house surface treatment fell. HORN invested huge sums in the project. Before that, the company had the manufactured tools coated at outside service providers. "We wanted to have all production steps of tool production in-house. Coatings was the last building block that was missing," says managing director Lothar Horn. At the end of 2004, HORN already received the second coating plant and in 2005 the first coating orders were handled process-safe by the in-house plants. In the following year, the third plant already followed, so that by 2006 HORN was already able to coat almost half of its tools in-house. Currently, over 80% of the tools produced are coated in-house.

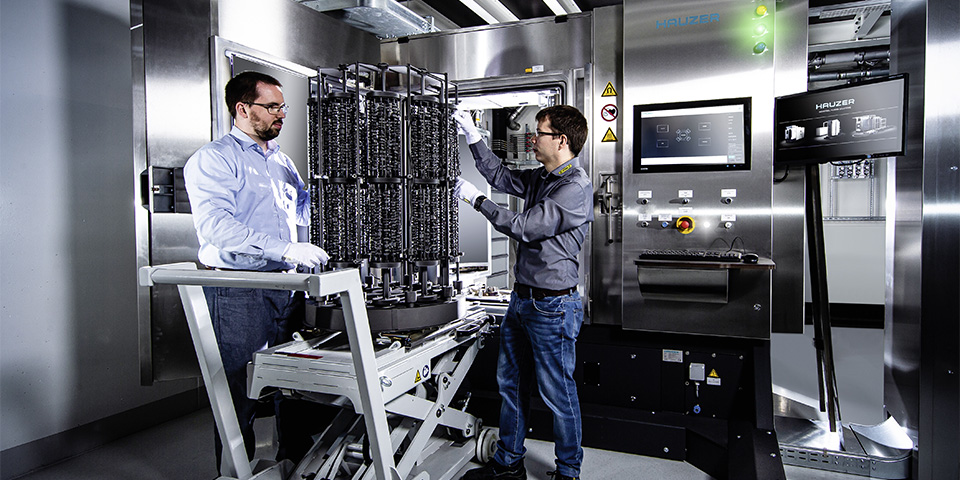

The department moved to the new Building 2 in 2016. On more than 1,200 square meters, there are twelve coating plants, several wet-blasting plants, two fully automatic cleaning plants and manual workshops for entering and handling coating orders. The processes could also be continuously optimized over the past 15 years. For example, several monitors in live mode show the ongoing and planned processes of the plants. Orders arrive at the department every two hours via the in-house transport system, which employees complete in three shifts. HORN opts for creativity also in the utilization of spatial capacities. For a new Hauzer coating plant, HORN built a second level in the department. This is where the peripheral equipment of the new plant is located, and there is also space for a second plant. Laboratory work provides comprehensive insight into developments.

Ongoing investments

HORN continuously invests in new and modern technologies. In 2015, the company CemeCon delivered the first (even worldwide first) of three HiPIMS installations to HORN. The High Power Impulse Magnetron-Sputtering technology offers some advantages and new possibilities in the coating of precision tools. With it, very dense and compact coating layers can be built up, which at the same time are very hard and tough. The layers have a very homogeneous structure and uniform layer thickness, even with complex tool geometries. "New paths in coatings, in cutting materials, in geometry. Coating technologies such as HiPIMS currently offer great opportunities to clearly extend tool life," Horn said.

HORN continuously invests in new and modern technologies.

In-house research and development

The research and development of new and existing coating and technologies contribute significantly to its success. HORN has an engineering team dedicated exclusively to this topic. "Since the beginning of in-house production, R&D projects together with installation manufacturers have already been carried out occasionally. Since 2014, when we started developing coatings, we have developed coating solutions - also independently of our partners - and gathered basic knowledge," says R&D manager at HORN, Matthias Luik. Customer requirements lead to development projects. The basic knowledge and experience gained are based on the research projects within the company and of course also with additional research bodies such as universities and other institutes.

HAZ - HORN Analysis Zentrum

In early 2019, the coating developers moved into a new laboratory right next to the coatings department. "To gain a deep understanding of our developments, we need to be able to examine the structures of our coatings using X-ray bending," explains

Coating engineer Bastian Gaedike explained. After the start of the project in August 2018, the XRDs (X-ray diffractometers) and furniture were ordered and the storage space was gradually converted into a modern laboratory. In addition to the XRDs, the development team has access to a REM (raster electron microscope) and other modern measuring equipment and machinery for R&D tasks. The research and development of modern coatings and build-up layers will play an important role for high-performance tool systems in the future. "New materials from aerospace and medical engineering will determine future coatings. Until now, they have been titanium and superalloys. The spectrum of highly complex materials, which place extreme high demands on machining, will continue to expand. We must ensure that we remain attentive and continue to develop high-quality coatings," Gaedike says.