CNC-controlled machining centers increase flexibility and output

A lot of companies have been looking for new opportunities in corona times. At the LenMatec Group in Tessenderlo, the organization continued to expand, with a reinforced focus on machine building and turning and milling. Last year, father Marc and son Lenthy Gys invested in a 3-axis vertical CNC machining center and a CNC inclined bed lathe, both supplied and installed by Promas. Result: increased flexibility and productivity on the shop floor.

At LenMatec, engineering, innovation and service are key. The family-owned company has been around for over 25 years and has evolved from a specialist in bolting services to a diversified industrial engineering group.

"From the early years, our focus was on providing on-site industrial services, allowing machine repairs to happen on site and minimizing downtime. Furthermore, among other things, we are a premium distributor of REHOBOT Hydraulics," explained Managing Director Marc Gys. "An important milestone in our history was the launch of the MiniFacer in 2008, a manually operated flange facer that I developed myself. However, the biggest turnaround came in 2020. Since our people were no longer allowed to work on site due to covid-19, we decided to refocus our organization and put more emphasis on machine building and turning and milling. Thus LenMatec became a group with three entities: Industrial Services, Sygma (machine building) and Turn and Milling."

Own work and services to third parties

At LenMatec Turning and Milling, the emphasis was originally on supplying to the other departments of the group, which significantly increased flexibility. Today, capacity is divided 50/50 between in-house work and services to third parties.

"We built a completely new CNC-controlled machine park in a short period of time. Two machines were commissioned in November 2020, but it soon became clear that there was a need for a third machine that could also machine parts for Sygma's larger machines," says son Lenthy Gys. "During our search, we came into contact with Promas, which convinced us with a demo of the 3-axis vertical CNC machining center type Hartford LG 1570 with Hartrol control. The machine was also available from stock, an added bonus. The minor adjustments were carried out by Promas itself. Three weeks later the machine was in our production hall."

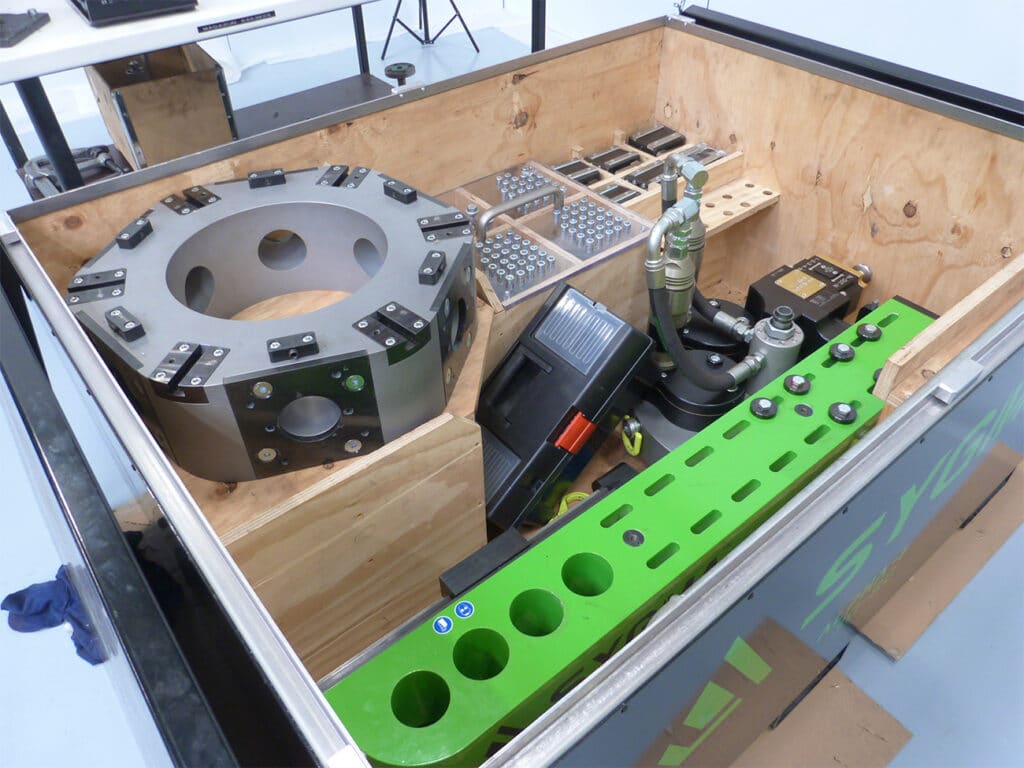

"This Hartford LG 1570 includes a 1600×650 mm table for workpieces up to 1000 kg. The X, Y and Z axes have a range of 1500, 700 and 650 mm respectively, the spindle turns a speed of 12000 rpm," adds sales manager Erik Kinat of Promas. "A few months later, the Gys family knocked on our door again, looking for a new lathe to replace an existing installation. We suggested a CNC inclined bed lathe TA20 YS640 from CMZ, with a maximum turning diameter of 460 mm and a reach on the Z axis of 640 mm. This machine is combined with a FANUC control and an LNS bar feeder. After a visit by LenMatec's management and operators to our booth in Brussels and a demo at a customer in the Netherlands, we received the order in September 2021. In December, the new lathe was delivered."

Standing still means going backwards

For the LenMatec Group, standing still is not an option. In a big year, the number of employees almost tripled from 7 to 20, and the number of machines increased with it.

"We recently moved into a new production hall. The Promas team came on site to move the machines from one space to another and reinstall them. This way downtime could be avoided," Marc and Lenthy Gys conclude. "Service actually runs like a thread through our cooperation with Erik and his team. We could count on expert advice and in case of questions or problems you can always reach someone who will look for a solution remotely or on site. Our machine park today counts 6 machining centers, but we continue to invest. After all, in addition to prototyping and small series, we want to produce larger series in the future."