CERATIZIT presents ambitious sustainability strategy

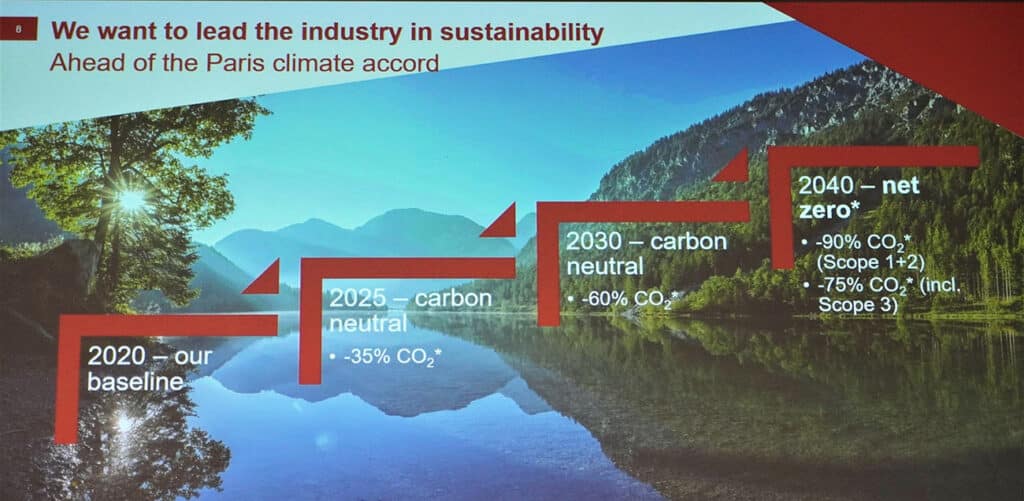

CERATIZIT presented an ambitious sustainability strategy on the occasion of AMB 2022 in Stuttgart. Using this strategy, the company aims to become the sustainability leader in the carbide and cutting tools industry by 2025. The goal is to be "CO2 neutral" by 2025 and "net zero" by 2040.

Executive Board Member Thierry Wolter announced the ambitious sustainability goals, which will affect and change the entire supply chain, during CERATIZIT's press conference at the AMB in Stuttgart. "Climate change is one of the greatest challenges of our time and requires the industry, too, to take a step in the right direction," Wolter said. So that CERATIZIT customers can also produce more sustainably, the company has set itself ambitious goals for its own products and services. "Our vision is to be the leader in sustainability in the carbide and cutting tools industry by 2025," Wolter continued.

Sustainability throughout the value chain

To become fully sustainable, CERATIZIT will in the future scrutinize the entire value chain with respect to environmental, social and governance criteria, and also include cooperation with partners. Initially, the focus will be on aspects that have the greatest impact on reducing CO2 emissions.

Three focal points to reduce carbon footprint

To drastically reduce its carbon footprint quickly, CERATIZIT is initially focusing on three main aspects. The decisive one is increasing the use of secondary raw materials to more than 95%. Compared to primary raw materials from ore, their processing requires 70% less energy and CO2 emissions are reduced by 40%. A positive side effect is securing the raw material supply chain, so both customers and CERATIZIT benefit doubly. Another focus is the power supply. CERATIZIT plans to switch the power supply of all sites to green power from wind, solar and hydroelectric sources in the coming years.

Closely related to the change in power supply is the issue of hydrogen supply. Hydrogen is widely used in the hard metal industry, particularly for the production of tungsten powder. Until now, this hydrogen has mainly been obtained from natural gas through steam reforming, so-called "gray" hydrogen. For the future, CERATIZIT plans to use blue hydrogen, which is extracted from water by electrolysis using green electricity. For this purpose, CERATIZIT will cooperate with its existing suppliers and also build its own electrolysis plants.

First milestone: carbon neutral by 2025

The first milestone in the implementation of the new strategy is 2025. By that time, CERATIZIT not only wants to be carbon neutral, i.e. offset all emissions throughout the supply chain. The goal is also to reduce actual emissions by 35% compared to the 2020 baseline year. The second phase, 2030, provides for a reduction of 60% compared to 2020 using further measures. The most ambitious goal, however, is to reach "net zero" by 2040 - a target that the Paris climate agreement only envisions for 2050. "Reducing CO2 emissions throughout the value chain by at least 75% by 2040 is a huge challenge. However, with future generations in mind, we see no alternative to this path and are happy to let our customers participate in this as well through products such as our 'green carbide', our award-winning SilverLine milling cutter with sustainability formula and a comprehensive range of services," Wolter explains the company's motivation.