BySoft 7: "TiltPrevention"

With the "TiltPrevention" auxiliary function, Bystronic increases process reliability in laser cutting. The intelligent function enables users to create cutting plans that minimize the risk of protruding parts. This reduces stopping cutting processes and downtime caused by collisions.

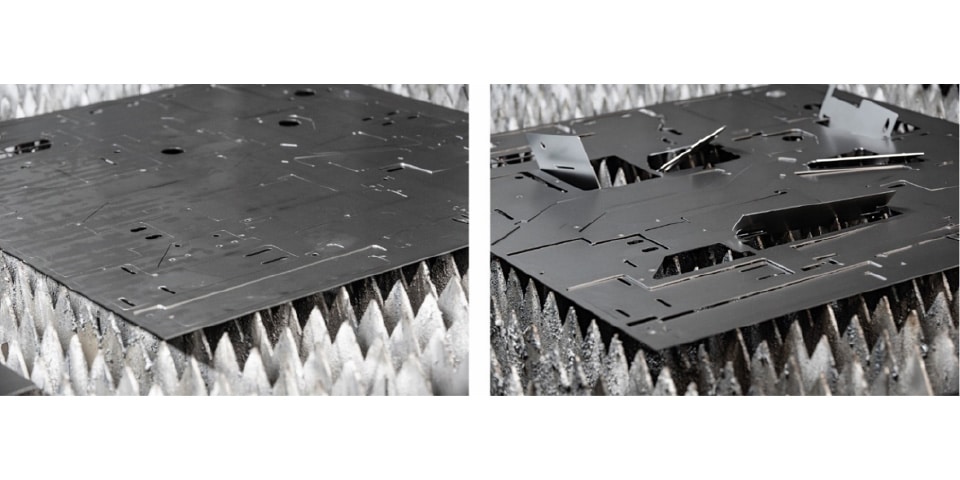

Tilted parts are a risk factor during the laser cutting process. They can cause a collision with the cutting head. This results in halting cutting jobs, rejected parts and, in the worst case, costly damage. However, they also complicate automatic unloading because the grippers of the automation system have difficulty picking up tilted parts.

Until now, the following were micro joints a time-intensive method for preventing cut parts from tilting. The software makes small connections between the contours of the part to be cut and the remaining grid in the cutting plan. In this way, parts remain attached to the surrounding plate after cutting. One disadvantage of this solution is: the cut parts must be reworked to remove the traces of the micro joints removal. Another disadvantage: automated unloading of the cut parts is hampered because the micro joints make it difficult to remove the parts from the plate.

Another approach is to use software to choose the paths of the cutting head during the cutting process so that, as far as possible, it bypasses risky sections where parts can tip over. However, this solution does not eliminate the cause of the problem: parts stick out, still pose a risk and are difficult for automation systems.

Algorithm generates the ideal cutting plan

With "TiltPrevention," Bystronic has now developed a new solution. In the future, BySoft 7 will use this intelligent auxiliary function to compile cutting plans in such a way that parts cannot tilt during the cutting process. This largely eliminates the need for micro joints.

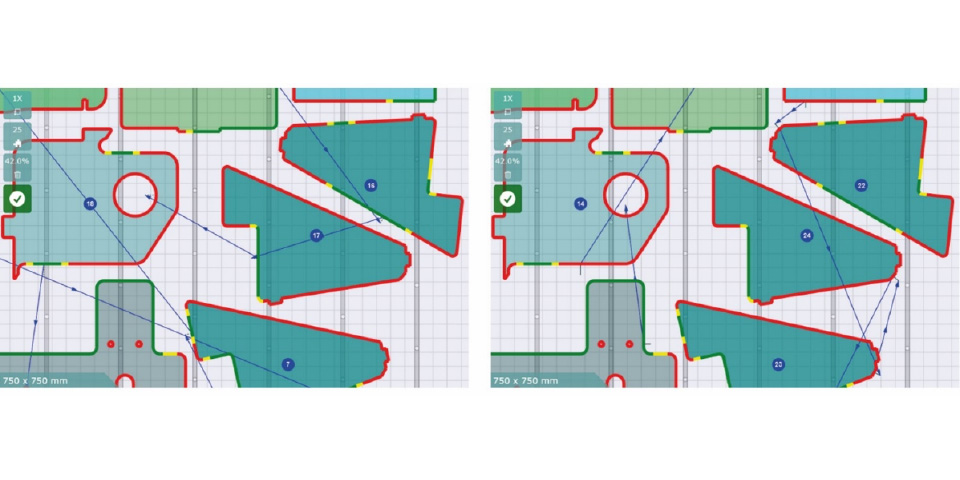

How it works. An algorithm calculates the mechanical behavior of the parts as they are cut from the sheet. To achieve this, "TiltPrevention" takes into account a large number of parameters: what is the density of the material being cut? What is the geometry and weight of the parts to be cut? What is the pressure of the gas flowing out of the cutting head during laser cutting and exerting pressure on the parts? How do the parts lie on the cutting grid? Are there sufficient contact points?

Next, "TiltPrevention" recommends start and end points of the laser so that tilting of parts after cutting is prevented as much as possible. In addition, the function provides the best possible route for the cutting head above the metal plate. This creates an ideal cutting sequence for all parts of the cutting plan. Cutting in such a way that the cutting head never moves over parts that have already been cut out.

Regardless of the users' experience level, "TiltPrevention" supports them with an ideal cutting strategy that can be automatically incorporated into the cutting plan. Users can make adjustments at any time using the simulation created by "TiltPrevention": modify the nests of parts, reposition the start and end points of the laser and add where necessary micro joints toe.