A correct saw blade increases accuracy and efficiency

The manufacturing industry must invest in skilled employees and high-quality machinery, but also choose the right tools. At SAE, a specialist in the production of stainless steel and aluminum parts, they found that out for themselves. The German manufacturing company replaced its existing saw blades with Jepson Power's DryTech® TCT technology. The result: increased accuracy, efficiency and productivity to meet the increasing demands of demanding customers.

Delay and high costs

SAE was a successful company, but was struggling to keep up with the increasing demands of its customers. The saw blades they were using at the time blunted too quickly, created far too many burrs and had to be constantly replaced. That led to shop floor delays and rising operating costs. "Our employees had to rework the workpieces too much. Every cut left burrs, so we had to grind and polish extra. In addition, the blades wore out quickly. As a result, production often stopped to replace them, which was not sustainable. We needed a long-life solution that would allow us to produce quickly and accurately without sacrificing quality," explains SAE's production manager.

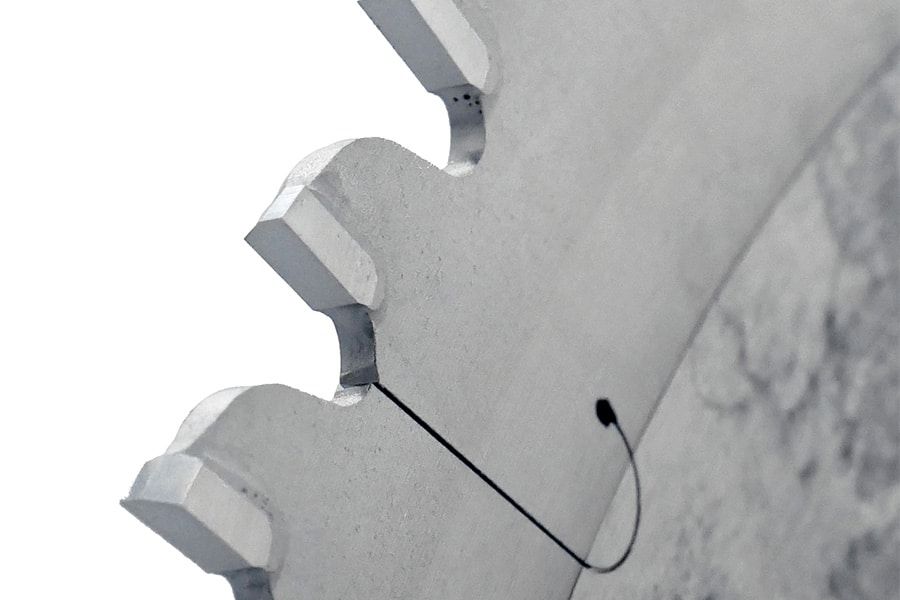

NSF-coated TCT saw blades

While searching for alternatives, SAE came across Jepson Power's DryTech® TCT saw blades. These are known for their fast, burr-free cuts without the need for coolant. The production manager contacted Jepson Power for a saw test. A demonstration with the NSF-coated TCT saw blades, designed specifically for stainless steel, followed at Jepson Power's in-house test center. These saw blades feature an aluminum-titanium-chromium-nitride coating, which reduces material adhesion and extends blade life.

Impressive

"The test results were impressive and so we were immediately convinced that this was the solution we needed. We switched to Jepson Power's saw blade technology and the impact was immediate. The cutting speed increased by 40 %. The carbide teeth cut through stainless steel and aluminum with ease, dramatically reducing cycle times. Rework has been reduced by 60 %. Cleaner cuts with minimal burr formation make time-consuming grinding and polishing almost unnecessary," explains the production manager. "In addition, the blades last three times longer. The NSF coating prevents material buildup, allowing the blades to be resharpened multiple times and reducing replacement costs. Finally, there is also less downtime and waste. Because the blades last longer and have fewer defects, overall efficiency improves and less material is wasted. The result is clear: machining time is cut in half and we save thousands of euros on blade replacement. Our workflow has completely changed."

Sustainable partnership

With decades of experience, a dedicated R&D department and a team of skilled product consultants, Jepson Power built a strong reputation for developing advanced, customized solutions. By incorporating their advanced saw blade technology, SAE not only streamlined its operations, but gained a competitive advantage. "With faster production, lower costs and improved product quality, we were able to take on more orders and strengthen our position," concludes the production manager. "This move not only allowed us to cut costs, but was also an investment in the future of our company. Today, we continue to work with Jepson Power, confident that they have the right tools to keep our production on the cutting edge."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Jepson Power GmbH.

Contact opnemen

Contact opnemen