50% higher production capacity after investment in Euromac punch-cutting cell

Euromac, the Italian manufacturer of sheet metal working machines has installed a fully automated punch cutting cell at German manufacturer KLEUSBERG, which punches, cuts, automatically removes and sorts sheet metal parts. "The investment provides a 50% higher production capacity, with which the new system has already paid off within a year," says Jannik Plicht, Senior Project Engineer at KLEUSBERG.

With a rental fleet of 34,000 space containers and 7,200 units sold per year, KLEUSBERG is one of the leading manufacturers of mobile space containers in Germany. At the production site, U-shaped parts for the walls and roofs of the containers were previously manufactured manually based on drawings - supported only by outriggers, shears, a swing bending machine and a punching machine. "This manual way of working could no longer keep up with increased demand from the market. Therefore, five years ago we started to focus more on lean production and we started looking for a partner who could offer efficient production solutions for parts in a wide variety of lengths and sizes," Plicht explained.

Punching instead of laser cutting

Because of the large number of different parts, a laser cutting system was initially considered. "But since we only use galvanized sheet steel, this was not ideal. Instead, we needed a punching machine that could also handle long parts without microjoints - and that was as automated as possible. Most suppliers could not meet these requirements. Eventually, we ended up at Euromac through our machine dealer. They not only presented a convincing concept, but also took into account our entire production process," says Plicht.

Intelligent combination of punching and cutting

Originally, KLEUSBERG planned a combination of punching and nibbling for processing large sheets (3 x 1.5 m). After analysis of the portfolio by Euromac, a punching machine with integrated clipping function was chosen. "Compared to nibbling, clipping offers the advantage of higher speed and clean cutting edges," explains Frank Heyerick, Senior Manager Central Europe at Euromac. "With the integrated angle shears, parts of any size can be accurately cut from sheet metal - ideal for straight parts for cabinets, cupboards, shelves and KLEUSBERG components, for example."

Euromac XT Shear: Precise cutting with more efficient material consumption

An additional element of the new production cell is Euromac's specially developed XT angle shears integrated into the XT punching machine. This eliminates the need for microjoint joints, increases cutting precision and cutting speed, and delivers 20% material savings compared to conventional solutions.

High-level automation

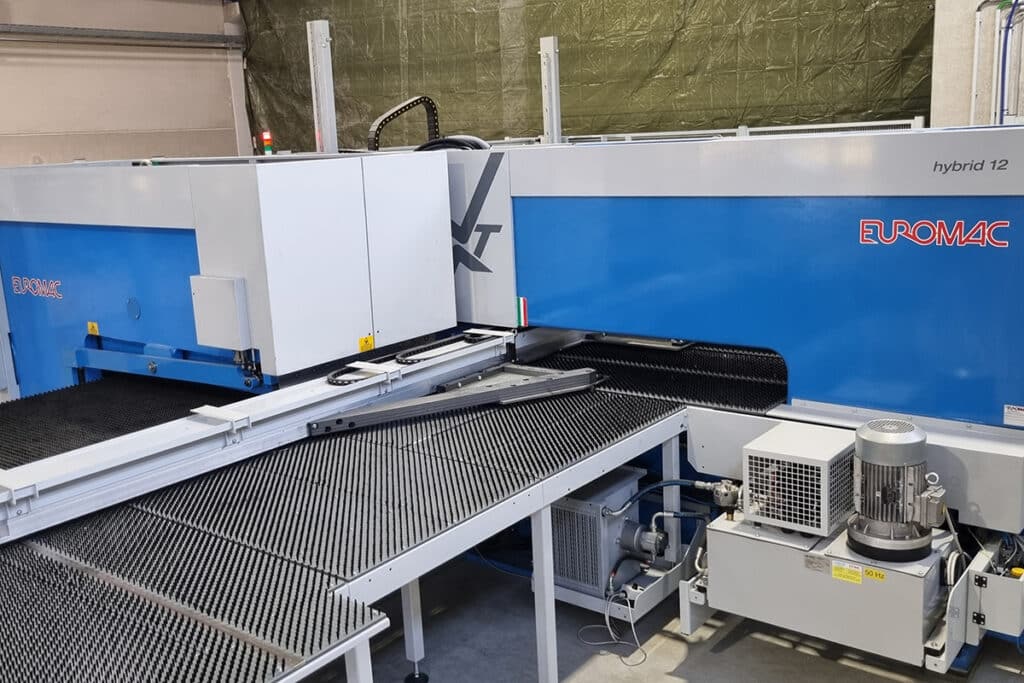

Euromac has seen sales in automation systems triple over the past 3 years based on the latest generation of punching machines and bending cells. The centerpiece of the new automated production cell at KLEUSBERG is the hybrid XT punching machine, expanded with a loading and unloading system, angle shears, robotic sheet removal and sorted stacking. The XT punching machine can process 3 m of sheet, without overpacking, in one process. On the infeed side is an automated sheet warehouse with two towers for up to 44 packages of sheet material. The corner shears can even process material thicknesses of up to 3 mm and - like the punching machine - are available in hydraulic, electric or hybrid versions.

Software

Working closely with Lantek, Euromac has developed a complete software suite that fully supports both stand-alone and complete automation systems and manages from a single workflow the entire production process from quotation to order, from nesting to work planning, from inventory to assembly, to shipping and invoicing.

The road to digital production

For KLEUSBERG, the switch from manual to CNC-assisted production meant a radical change - both technically and organizationally. "We had to digitize all drawings, of which over 90% of our design data has now been digitized. At the same time, we expanded our production hall and are now preparing the step to link with ERP."

Short payback period

With the commissioning of the new production cell, KLEUSBERG was able to say goodbye to six previous machines. "Our production capacity has increased by 50%, without overtime. If you compare the investment costs with the savings, the new system paid off within a year," says Plicht, drawing a positive conclusion.