Machining centers, automation and digitization from a single source

Hermle offers a full range of five-axis machining centers and can combine them with automation solutions and building blocks to digitize processes. Customers can thus increase productivity without additional personnel. Automation solutions range from easy-to-operate pallet changers and handling systems for pallet provisioning to robotic systems and, increasingly, total solutions, where a single robot is used to operate several machining centers. At TechniShow, Hermle Nederland BV will demonstrate a C 250 with RS robotic system and a C 42 with HS flex handling system.

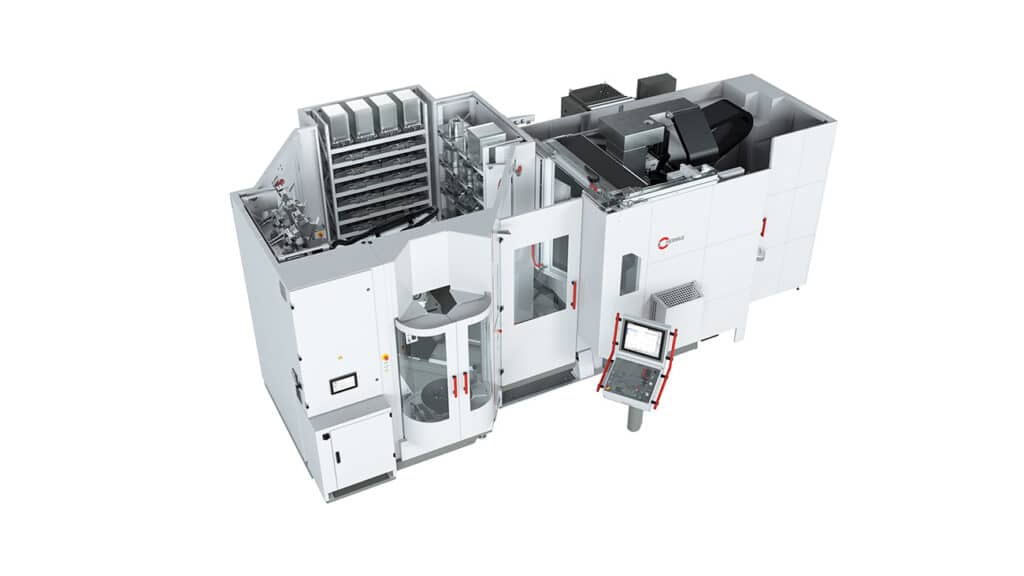

HS flex

The HS flex handling system consists of several components, which are delivered and set up as a complete unit. Installation of the storage modules - just like Hermle's machining centers - takes little time. The user can therefore get to work quickly. The mineral-cast flat bed, on which the three axes of the handling unit stand, is characterized by ergonomic access for the user.

The two wing doors, which have already proved their worth in Hermle's robot systems, have a dual function. When the workpiece is changed, they block the operator's access to the workspace. When the part is being machined, the operator can still keep an eye on the workspace and intervene if necessary, but access to the handling area is blocked.

unit concluded.

The turning, lifting and linear axes guarantee precise transport of workpieces up to 450 kg, including pallets with dimensions of up to 500 x 400 mm, between preparation, storage module and work area of the machining center. To reduce operator errors, the maximum workpiece height is already determined during preparation so that workpieces with excessively large dimensions are not brought in.

Much attention was also paid to the development of the storage module. One module is installed as standard, optionally a second module can be added. These modules are constructed as shelves and offer maximum flexibility in terms of layout for pallets and workpieces. Up to four racks with a total of 20 pallet spaces per module can be integrated. A storage generator from Hermle monitors weight and dimensions of pallets and workpieces. In this way, storage capacity can be determined quickly and easily.

RS 1

The robot system RS 1 is an automation solution for handling workpieces and pallets, characterized by maximum flexibility and productivity. The racking concept ensures a high degree of autonomous operation and gripper changeover is automatic. The fully elaborated preparation zone allows new pallets and workpieces to be prepared already while other parts are being processed.

There is more, however, because this system is extremely flexible. For example, RS 1 can be coupled to one or two machines. Upgrading from one to two machines is also possible at a later stage. Expansion with a third shelving system, a washing system, a measuring system or an automatic transport system is also possible. Thanks to the floor space of only 12 m², operators always have free access to the work areas of the linked machine(s).

Robotic system RS 1 can be combined with Hermle's C 12, C 22, C 250, C 32, C 400 or C 42 machining centers. Automation in single systems is controlled via the Hermle Automation-Control-System (HACS) or the SOFLEX production control system. In solutions with two machining centers - of the same type or different models - the RS 1 is always controlled with SOFLEX. NC-controlled clamping systems and grippers allow fully automatic changeover of workpieces. The NC grippers and automatically adjustable clamping devices adapt to the workpieces due to the large gripping and clamping range, making manual intervention virtually unnecessary.

The intuitive operation and clear structure of the automation software Hermle Automation-Control-System (HACS) help avoid errors. All relevant data, such as system overview, work plans, time schedule and tool overview, are visualized. In addition, both lead time and tool usage are calculated in advance. All prepared parts are automatically entered into the planning and priorities can be adjusted at any time - via Drag & Drop and always with optimal visualization.