Machineering 27 - 29/03/2019 | Everything to Make It

From March 27 to 29, the largest palace at Brussels Expo will be transformed into a true manufacturing platform. Machineering will bring together all machine technology, software, materials and solutions for the smart design, engineering, transformation, manufacturing and assembly of products, components and machines. An appointment not to be missed with the future of manufacturing.

With the transformation from MTMS-Machineering to Machineering, organizer Invent Media wants above all to put on the map a fair that opens the door to all facets of making. Managing director Karl D'Haveloose: "Machine technology is at the heart of the fair. There are no more bad machines, they are becoming smarter and autonomous. It is the engineering, software and choice of materials that will make the future product perform. Far-reaching automation and digitalization are advancing, as well as the combination of different production techniques for greater speed or energy efficiency, for example. So machines without the right engineering technology are only half the battle. There is a growing realization that manufacturing today is an all-in model. And then, as a trade fair, you have to present it that way. At Machineering you need to be there to discover how, with what and with whom you will make new components in the future." In other words, networking will be a key feature in the factory of the future. "The customer is no longer looking for a drill bit, but for the one who guarantees the drill bit. He wants solutions instead of suppliers. The silent subcontractor is disappearing, the new subcontractor is already co-designing the product. This requires specific know-how and design knowledge." No better momentum than a trade show to discover new partners.

Ten technology routes

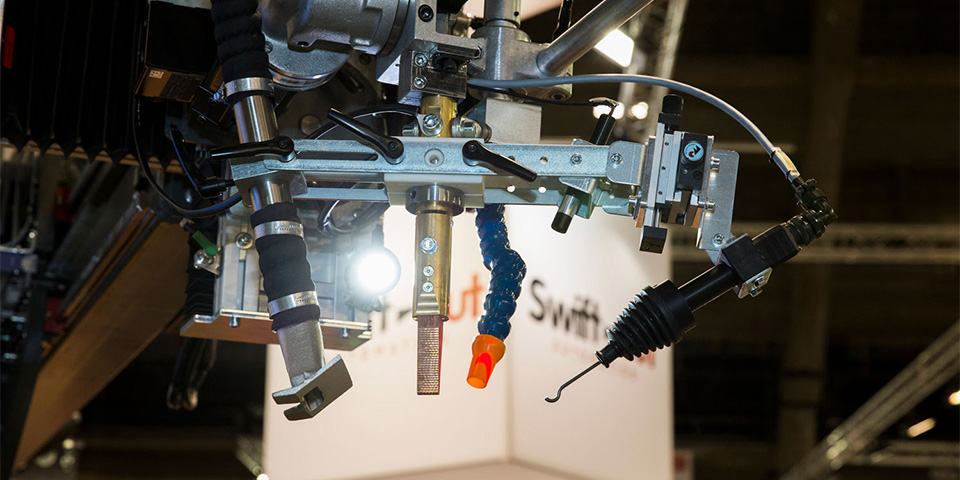

The concept throughout Machineering are the ten technology routes: testing & measuring technology, handling & robotics technology, engineering & material design technology, machining/milling technology, cutting & forming technology, machine maintenance & spare parts technology, welding & surface technology, digital, smart é data driven manufacturing technology and additive & new manufacturing technologies. They give visitors a handhold, a guide along the various booths. "Automation and digitalization are game changers. They require a new organization, a new model, a new approach and that requires different types of employees and investments under the form of integrations and IT. Everyone in mechanical engineering, manufacturing, and subcontracting does have their own piece of the puzzle. Thanks to the routes, a company can estimate for a team of management, engineering, maintenance, automation, IT ... who will take care of which piece. The idea is that after the visit the puzzle pieces are put together internally," says D'Haveloose.

Expert classes and 3D Feasibility Platform

Those looking to learn more about manufacturing of the future should also attend Machineering. "There will be at least four expert classes each day. These are combinations of use cases and strategic insights," D'Haveloose points out. "A new initiative that is also taking shape now, in cooperation with Flam3D and colleges, is the 3D Feasibility Platform. We make a general appeal to visitors from mechanical engineering, metal and plastics processing: can I print this? The idea is for visitors to come to the fair with their existing or new components to be made and see what parts are possible through AM technology and combinations. A team of experts will form the point of contact and will also give a daily session on what criteria, what type of parts are important to take the step or not."