Coming out big with new machines and novelties

Also at the upcoming EMO, machine manufacturers will show their latest models and novelties in a big way. Bendertechniek wants to give you a preview of the latest developments of the various brands. The sales team of Bendertechniek will be present the entire week at all stands of its suppliers: Juaristi, Lagun, Geminis and Zayer. Of course, you are also welcome to visit one of their high-end machine suppliers such as Matsuura and Muratec.

Juaristi has invested heavily in development of new machines in recent years. In addition to the existing boring mills, a complete line of large five-axis machines with high-torque milling heads and larger pallet changes of 1,250 by 1,250 mm or more was developed. In addition, the newest milling head will be introduced at EMO: the ACD7. This milling head can run at 6,000 or 8,000 rpm and has a torque of 3,000 Nm and 60 kW. Furthermore, it is equipped with two torque motors for stepless turning at any clean angle. The body`s are hydraulically clamped with 20,000 Nm. The advantage of this is that positioning is faster because two bodies can rotate simultaneously. Furthermore, Juaristi has invested heavily in 4.0 software for production management and monitoring. The machine on display is the TH3-MT. This is a five-axis multi-process milling, drilling and turning machine.

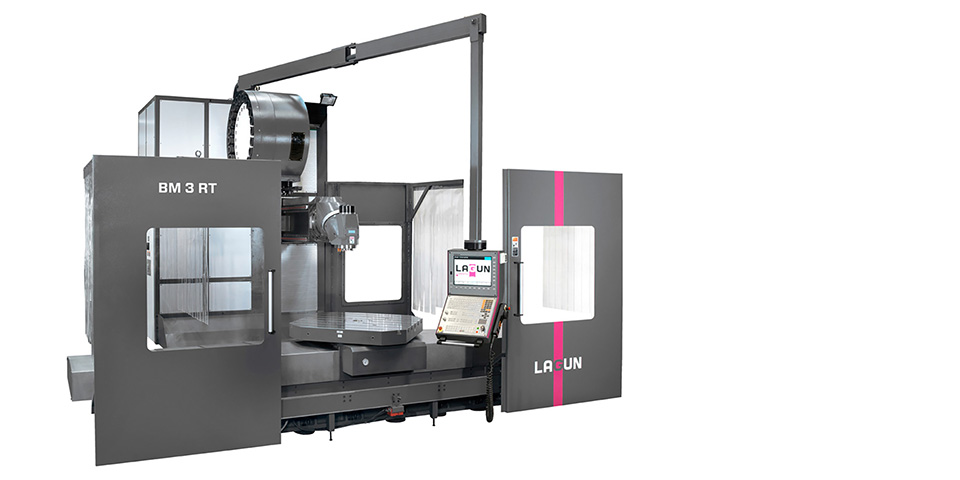

This BM3-RT bed milling machine from Lagun is equipped with a 1,600 x 1,200 mm rotary table and milling head with 2.5° on both bodies.

Lagun

Lagun will be showing the BM3-RT. This bed milling machine is equipped with a 1,600 x 1,200 mm rotary table and milling head with 2.5° on both bodies. It is full enclosure equipped. A big plus is that it is also available with a V-axis. Because of the movable column, the range in conjunction with the ram (1,300 mm extendable) is very large and diameters of 2,500 mm can be achieved. The table is also available in, for example, 1,500 x 1,500 mm. Lagun is also working on a milling head with torque motors to achieve stepless positioning. This milling head will have a five-axis simultaneous function as an option. Furthermore, a block bed machine with an integrated rotary table in the bed will be launched at the end of this year. This option gives the machine more capabilities and will compete with the multi-axis machining centers but with larger size and heavier power.

Zayer's newly developed Arion G turning milling center makes its German debut at EMO.

Geminis

Geminis, the Spanish supplier of large flatbed lathes is packing big at EMO with the new GT5i G2 lathe. This machine has been completely redesigned to have better ergonomics and a more favorable footprint. Furthermore, the machine will have many extras for smart manufacturing. For example, this machine has a dashboard with additional options to control maintenance and running process.

Zayer

Zayer's newly developed Arion G turning milling center is making its German debut at EMO. This multitasking machining center enables users to perform complex turning and milling tasks flexibly, versatile and ergonomically. The Arion G comes standard with the patented Zayer 30° universal milling head. The milling head can be used both in positioning mode and for simultaneous milling with continuously rotating axes. A motor spindle in the milling head makes a speed of 15,000 min-1 possible. With a drive power of 42 kW, a maximum torque of 200 Nm can be called up. In addition, mechanically driven milling heads with speeds of up to 6,000 min.-1 available. The turning-milling center has a rotary table with a diameter of 2,000 mm. The rotary table is driven by a powerful torque motor that achieves a maximum torque of 20,800 Nm.

Dynamic, user-friendly production solution

The Arion G is a rigid yet dynamic production solution that is easy to operate and maintain. Sensors in the linear drives automatically adjust the dynamics of the machine to the machining processes. Accelerations up to 4 m/s2 and abrupt directional changes are possible at any time, depending on the workload. Optimizations can also be performed by the operator through special cycles. Large sliding doors, an automatically opening and closing roof and the use of transparent panels in the cladding provide a good view of the work area. Intuitive operation is guaranteed thanks to the large, non-reflective touch screen. The new, interactive manuals can be called up directly on the controller display to make working even easier for inexperienced operators.