Quality tools increase profitability

Perfection leads to success, especially in the world of tools. Professional tools must be absolutely reliable and functional. The Hoffmann Group, the market leader in quality tools, offers a wide range with more than 70,000 tools for cutting, machining, clamping and grinding, as well as personal protective equipment (PPE) and solutions for company equipment. Under the motto "From Concept to Reality," the company is showing at EMO how it can support the production process with physical and digital products. New developments such as the GARANT MasterTap Inox, the GARANT Master Alu milling line and the GARANT Xtric centric machine clamp are on display.

The new centric machine clamp GARANT Xtric for clamping raw and machined parts is equipped with an innovative jaw quick-change system.

The metal-processing sector looks completely different from roughly ten years ago: no more large production runs, extensive automation, even stricter requirements regarding quality and delivery times, and a huge shortage of technical staff. For optimal profitability, metal processors rely more than ever on the reliability of tools in addition to machines and personnel. "Over the past hundred years, we have constantly reinvented ourselves. We have adapted to changing market conditions, anticipated new developments and introduced innovative products and services," states Patrick Dehaene, sales manager Belgium at Hoffmann Group. "Our range today includes more than 70,000 tools for cutting, machining, clamping and grinding, as well as personal protective equipment (PPE) and business equipment solutions. We distribute products from more than 500 brands, but have also been developing our own products for a long time. Thus, we introduced the premium brand GARANT in 1973 and ten years later the first products of the quality brand HOLEX. Every day, 3,000 employees worldwide are ready to support more than 135,000 customers to optimize their production processes."

Innovation trumps

Whoever says Hoffmann immediately thinks of the orange catalog. In this anniversary year, edition 50 of the "tool bible" will be published in eighteen languages and in a print run of 1.1 million copies. The Hoffmann Group continues to invest in the expansion of its range as well as the development of new solutions and the optimization of existing products from its own range. Under the motto "From Concept to Reality," the specialist will show at EMO how it can accompany the entire production process with physical and digital products. On booth A06 in Hall 3, the company will present innovative solutions in the areas of machining, clamping technology, measuring technology and digital services.

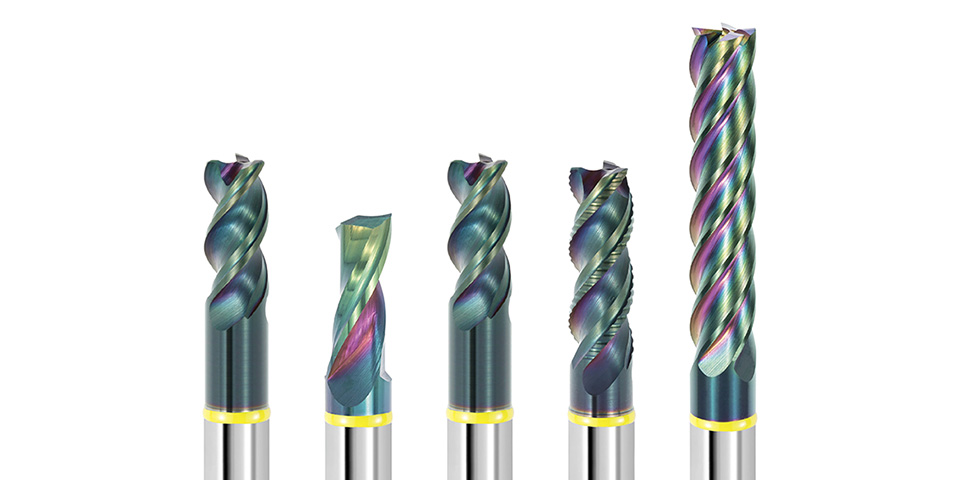

The new GARANT Master Alu milling line for aluminum machining includes tools for every application.

GARANT innovations

For example, Hoffmann will demonstrate the GARANT MasterTap Inox, the GARANT Master Alu milling line and the GARANT Xtric. The GARANT MasterTap Inox, the newest member of the successful tap series, combines high-quality cutting material, innovative geometry and state-of-the-art coating technology for perfect threaded drilling in stainless steel. The GARANT Master Alu milling line includes a complete tool series for every application: from the single cutter shank cutter and the serrated spindle cutter to the chamber cutter and torus cutter. "Another highlight is the GARANT Xtric, a centric machine clamp for clamping raw and machined parts, eliminating the need for preforming the pieces. This clamp is equipped with an innovative jaw quick-change system," explains the sales manager Belgium. "The attachment jaws can be changed or rotated 180° via a click mechanism in just a few simple steps and without tools. Thanks to these rotatable set-up jaws, the Xtric offers a particularly large clamping range." Furthermore, the Hoffmann Group is presenting numerous additions to its existing programs, including TPC tools from the GARANT Master Titan milling line, a changeover plate and VHM parabolic cutter for Parabolic Performance Cutting (PPC) as well as the latest version of the measuring microscope GARANT MM1, with up to ten times larger field of view.