Producing. Controlling. Trust. - ZECHA solutions for the machining of the future

Within modern machining, dimensions and tolerances have long since ceased to be the sole determinants of success - but technological understanding, share of in-house production and the ability to match tools precisely to real requirements. With the IGUANA and MARLIN 3D series, ZECHA brings together two solutions that embody these principles in a special way: manufactured with state-of-the-art laser technology, designed for the highest demands - and the result of consistent developments based on genuine manufacturing innovation.

The basis of both series is high-precision laser technology that surpasses classic grinding and coating processes in many ways. The tools are created not by standard processes - but by targeted shaping, defined structures and edges ground to the micrometer. This innovative manufacturing process opens up new possibilities in terms of shaping tool geometry that is precisely tailored to the intended application - with precision and longevity that are evident during use.

The IGUANA-SERIES have been specially developed for machining copper, non-ferrous metals, precious metals as well as abrasive plastics and non-ferrous alloys. Their strength lies in the diamond coating lasered on both sides that produces an exceptionally sharp cutting edge of only 1 µm. This precisely shaped edge provides lower cutting forces and reduces thermal stress - a clear advantage when machining sensitive or heat-conducting materials. As a result, the tools not only achieve a consistently high surface quality, but also a significantly longer service life. That this is not mere theory was demonstrated during the "IGUANA Milling Challenge": for more than 641 hours, a 1-mm tool milled copper medals in continuous operation - with consistent geometry and quality down to the last part.

The MARLIN 3D LASER-SERIES is aimed specifically at users who need to precisely machine particularly hard materials such as ceramics and sintered carbide - i.e. materials that until now could only be partially machined by grinding. By using specially configured PKD cutting edges combined with high-precision laser geometry, ZECHA now makes milling an economical and process-safe alternative in these areas as well.

This development offers new possibilities in component design and within the process chain, because even complex 3D geometry can now be milled directly - with shorter machining times and significantly higher efficiency. Tools with up to 42 cutting edges enable a high volume of machining with, at the same time, excellent dimensional stability, even on the finest contours. This is complemented by an integrated cooling system that ensures targeted temperature conduction and safe chip removal, even at high speeds. The result: reproducible precision, longer service life and excellent surfaces in materials that were previously only limitedly accessible for machining.

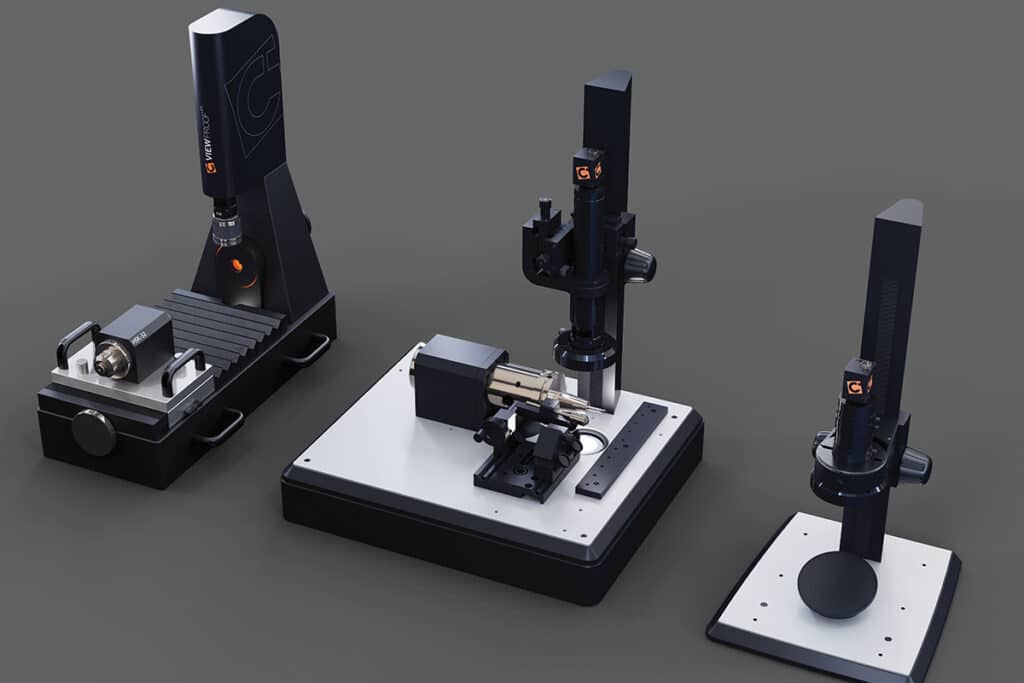

In addition to the development of tools, ZECHA also places the topic of quality assurance more to the fore. With the C-VIEW technology, a modern measuring system is available that has been specially developed for the requirements of precision machining. It enables precise checks of tools down to the micrometer, directly in the clamped position - i.e. before, during and after machining, without having to remove them from the toolholder.

Geometry, lengths, coating characteristics and, in particular, also the circularity can thus be checked precisely and reproducibly - under real conditions. Thanks to integrated HSK spindles, automated software functions and intuitive user guidance, C-VIEW can be seamlessly integrated into existing processes. The technology thus ensures not only optimum test accuracy, but also efficiency, traceability and stable processes in quality control - an additional building block for documented accuracy in high-quality machining.

The demands on tools and processes are constantly increasing - at the same time, workpieces and tool geometry are becoming increasingly complex and filigree. ZECHA responds to this development with a clear commitment: maximum precision, customized solutions and genuine support. This begins as early as CAD/CAM programming and extends to optimally matched tool selection, strategy development and cutting data design - always adapted to workpiece, machine and application. Our customers appreciate this hands-on, solution-oriented approach that goes far beyond the sale of tools.

Because precision and quality are the key to success - especially in highly sensitive industries such as medical technology and dental technology, the watch industry, the electronics and chip industry or tool and mold construction.... ZECHA's goal here is clearly defined: to provide optimal solutions - for any application, any material and any size, no matter how small.

In addition, ZECHA Hartmetall-Werkzeugfabrikation GmbH is pleased with the close cooperation with de Ridder, a renowned partner in the Netherlands. De Ridder has for many years specialized in the sale and support of high-precision machine solutions for turning, milling, grinding and erosion.

Through this cooperation, Dutch customers benefit from a competent local contact for ZECHA's high-quality precision tools, combined with technological know-how and application-specific advice in the field of machining production.

Together, ZECHA and de Ridder pursue the goal of promoting innovative manufacturing technologies and strengthening sustainable production processes in the metalworking industry.

Get more insight into these solutions at the Precision Fair 2025 - on Nov. 12 and 13 in 's-Hertogenbosch, booth H6-252.