Making a difference with quality and service

Downtime is something manufacturing companies cannot afford. Therefore, it pays to look beyond the performance on paper of a machine tool and partner with a partner that offers excellent service and support. MT-service grew out of the technical service business and has retained that affinity for repairs, maintenance and overhaul. It is also fully committed to quality brands that do just that little bit more for their end customers. A good example of this is TOS Varnsdorf. In between some factory visits in Belgium and France, Metaalvak had the chance to sit down with owner Jan Rydl. A conversation about the future of the company and that of the manufacturing industry.

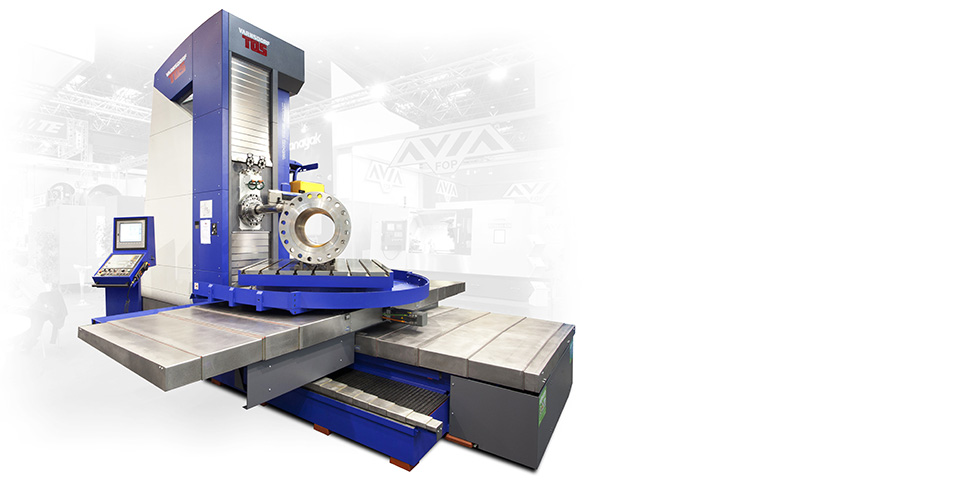

The future is built on the past. For TOS Varnsdorf, its roots reach back to 1903 when a German entrepreneur began building machine tools in the Czech village of Varnsdorf. After World War II, however, it was incorporated as a state-owned company. The production of boring mills received full attention from then on, and the name TOS Varnsdorf also dates back to that period. The title of state company was by no means synonymous with resting on one's laurels. "Production was fine-tuned and investments were made in the development of new machine types. In 1963, for example, the first numerically controlled machine rolled off the assembly line here," says owner and managing director Jan Rydl. "But the collapse of the Soviet Union created a lot of uncertainty. My father fortunately managed to convince the Czech authorities in 1995 to privatize the company and put it in his hands. It would have been a shame to let these production facilities go to waste." It became a whole new start that required a lot of investment to make it a modern company with a clear vision for the future.

Close ties, close to customers

Today, just under 500 employees work for TOS Varnsdorf, spread across several locations. In just a few decades, the company evolved into a world player in horizontal boring mills. "Already fourteen years ago we opened a production facility in China, for us the first step to distant markets. Important because we absolutely want to be close to our customers. As management ourselves, we work with very short decision lines and try to visit our factories often. Close ties are important to us, that is the foundation of a family business. If you then get to hear first-hand where the needs of metalworkers lie, you can move quickly to go to market with the right machines and solutions." Branches in Russia and Taiwan soon followed. A production facility on U.S. soil should follow in the future. In addition, of course, numerous countries and regions have been given their own sales and service departments in order to be helped quickly." For Rydl, service really is the way to make a difference. "If you put the boring mills of different manufacturers side by side, there are few profound differences left. Support is the way to stand out. That's why we want to be present worldwide, so that no time is lost. We must not let our customers' production capacity come to a standstill."

Own technical school

As in Belgium, the Czech Republic is facing a shortage of technically skilled personnel. Instead of waiting for white ravens to find their way to TOS Varnsdorf, the boring bar manufacturer took matters into its own hands. "Three years ago we established a technical school for secondary school students. This year we will see the first batch graduate," Rydl says proudly. "We do that with a cluster of companies, where the 40 to 45 students we have per year can do internships. After all, to keep growing we will need well-trained employees. If they succeed, they are sure of employment. But they don't just get it as a gift from us. Above all, we want employees with the right mindset. Technology advances so fast, technical knowledge has to keep up, but it will only bear fruit if the company culture is right. Therefore, above our school hangs a sign that reads roughly the following in Czech: 'If you don't know something, we will teach it. If you can't do something, we will explain it. But if you don't want it, we don't need you'."

More modularity

The need for well-trained people also has to do with the increasing complexity of machines and machining processes. "The pieces are getting more complex, so the machining processes also have to be able to handle more. And with the Industry 4.0 story, the demand for more diagnostic tools and remote diagnostics has increased. On the other hand, you have to make sure your machines are easier and easier to operate. Not a simple task," Rydl confesses. To achieve this, the engineers at TOS Varnsdorf are focusing on standard lines with more modularity. That simplifies assembly but at the same time gives customers more options to start personalizing their machine. "They already have the advantage of choosing between horizontal and vertical to meet their specific requirements. Modularity also allows them to take only those bells and whistles on the machine that add value to their production process. That in turn gives our machines an edge to achieve a competitive price-quality ratio."

Pushing boundaries

TOS Varnsdorf wants to continue on the same lines in the future. "Today our machines, our service, our people are synonymous with quality. We want to maintain that. Our R&D department is working hard to keep pushing the technical parameters so that our customers can master more and more technical challenges," Rydl concludes.