Know-how in machining for the most productive tools

The TechniShow is the setting par excellence for highlighting innovations. As usual, HORN will show how it has poured its know-how in machining into new tools. Among others, it will highlight jet whirling, high-speed whirling, roll cutting tools for larger modules and the Supermini HP.

With jet whirling, HORN demonstrates its know-how in thread whirling. In cooperation with W&F Werkzeugtechnik, a whirling system with a supply of coolant was developed. As a result of direct cooling during cutting, the system enables high tool life. In addition, in combination with the stable swirl generator, the system realizes higher surface quality. Through the interplay of the cone system and the flat support at the patented W&F interface, the swirl head achieves high changeover accuracy and user-friendly changeover with only three screws. The internal supply of cooling reduces the risk of chip accumulation between the change plates. Swirl head changeover time at the swirl generator interface is under one minute. The interface offers a turnover and oscillation of 0.003 mm. The maximum speed is 8,000 rpm. The swirl heads are available with three-edge type S302 or two-edge type 271 change plates. The cutting circles are available with a diameter of 6, 9 or 12 mm. Swirl generator adjustment interfaces are available for all regular long-turn machines.

The tool offers the possibility of producing large toothing parts on universal machines that previously required special toothing machines.

High-speed swirling

Another new process HORN is showing with high-speed (HS) whirling. This technology is being shown in cooperation with machine manufacturer Index-Traub. HS whirling offers a high increase in productivity due to parallel turning and whirling machining. In the process, the speed is so high that a turning process can be performed before the whirling process. The turning tool positioned before the whirling tool reduces the volume of material, which would otherwise have to be removed by the whirling tool. This enables higher tool life as well as higher surface quality. The swirl heads are similar to traditional swirl heads. Only the cutting inserts have a different geometry. Fabrication of single and multiple threads is possible with only one cutting insert.

With jet whirling, HORN demonstrates its know-how in the field of thread whirling.

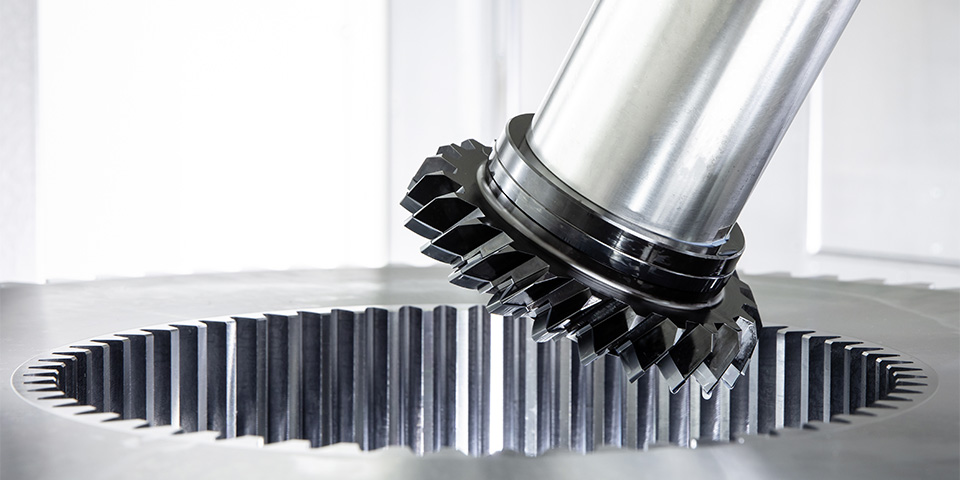

Leveraging know-how for larger roll cutting tools

The roll-stitching of larger modules requires large and rigid milling/turning machines that enable the required synchronization between workpiece and tool spindle. After the experience with small solid carbide roll cutting tools, HORN utilized the accumulated know-how for larger modules. The tool system is based on cutting plate type S117. The patented plate seat of the single-cut tool ensures precise tension and positioning at high rigidity of the overall system with high repetition accuracies. The ground chip guide level and direct screw connection of the cutting plates ensure very good chip removal from the machining zone. All blades are directly cooled by the internal coolant supply. HORN roll cutting tools are specially matched and built for the application. Each application is checked for feasibility by HORN technicians before execution, and tool design and process recommendations are discussed with the user.

Supermini HP: multi-purpose tool for high cutting values.

Supermini HP: multi-purpose tool for high cutting values

The new geometry Supermini HP is suitable for drilling, turning out, flattening and over-turning. With the new blade geometry, higher cutting values and feed movements are possible. When turning out, a flat 90° shoulder is created at the base. The drag cut (Wiper geometry) ensures high surface quality even at high displacements. In addition to turning, the system is also suitable for full drilling with a diameter of 3 mm to 7 mm. The Supermini HP offers the option of turning out the inside contour immediately after drilling - without a tool change. The single-cut design also allows different bore diameters to be produced with one tool. HORN offers the tools for optimum clamping control with and without clamping guide level. For turning operations, the variant with chuck level is recommended.

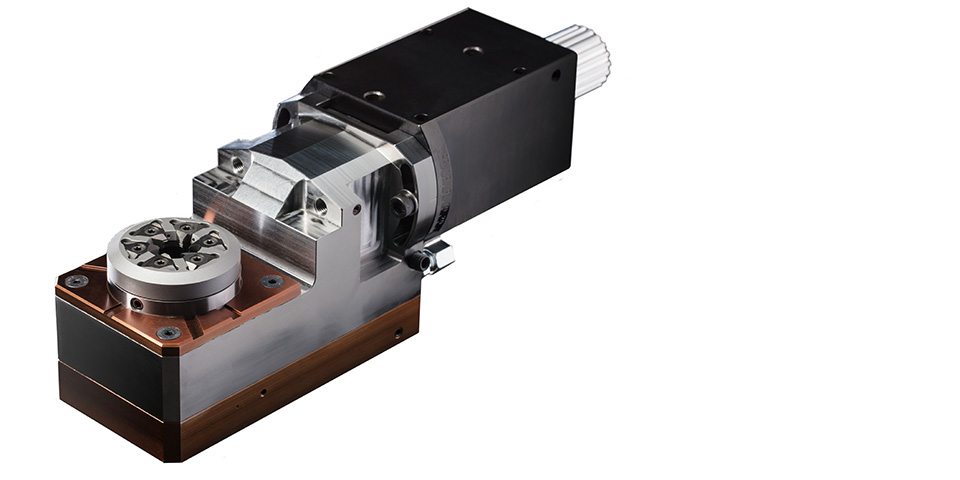

Higher holding force cutting plate

In addition, HORN developed a new holding system for the Supermini Typ 105. The new tension no longer uses the casing surface, but a tension wedge at the front. This leads to a higher holding force of the cutting plate and thus high rigidity of the entire system. The new tension also increases the repeat precision when changing the cutting plate and ensures better utilization of the available construction space by front operation. This is a great advantage on long-turning machines, since the user can change the cutting insert without having to dismantle the toolholder.