Automation, digitization and maximum machine power

Today's manufacturing industry is increasingly revolving around the smart factory' and Industry 4.0. Intelligent job processing, transparent production processes, smart operation of machines, paperless production and advanced technologies are the building blocks of this revolution. With the development and production of innovative systems, Hermle AG is also doing its part. At EMO, the machine builder is once again presenting six new systems. Four of them will also be demonstrated live at booth C36 in Hall 12. All under the motto "smart technology for the production of tomorrow.

When Berthold Hermle founded his screw factory and mold turning shop in 1938, he could not have imagined that his company would grow into one of the leading machine builders with more than 26,000 systems installed. At Hermle, everything revolves around milling. Under the slogan "better milling," the German specialist continuously develops high-quality and highly innovative machining centers and other solutions. Also at the EMO, Hermle is introducing six machines, four of which will be demonstrated on the booth. In addition, the 560 m² booth also includes a special show around digitalization in terms of production, operation and service. These elements form the foundations for intelligent job processing, transparent production processes, smart operation of machines, paperless production and advanced technologies, in other words for the smart factory and Industry 4.0. Finally, a C 32 U machining center will be equipped with VDW's new UMATI interface and the Generative Manufacturing Department will display components manufactured with MPA technology.

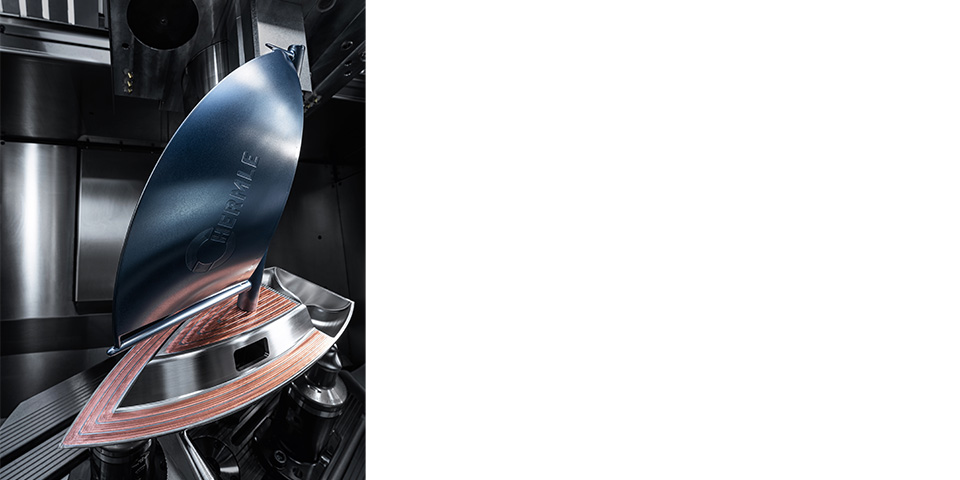

A sailboat manufactured in a generative manner with MPA technology from Hermle.

(Image: Maik Goering Photography

Innovative machining centers

Among other things, the Maschinenfabrik Berchtold Hermle AG will demonstrate two innovative machining centers from the High-Performance-Line. The C 42 U MT dynamic uniquely combines the technologies of milling and turning. Both technologies will be shown at the booth in a single fixture during the production of a gear housing in 1.2312 for aerospace technology. Trochoidal turning is also used in this application. With the five-axis machining center C 32 U dynamic, the spindle performance and the very robust construction of a machine in mineral casting technology are the main focus. This spindle guarantees speeds of up to 15,000 1/min, a power of 42 kW and a torque of 148 NM. A "heavy machining" demo will show what is possible with a combination of intelligent milling strategies and state-of-the-art tool technology.

The modular and compact robotic system RS 05-2 combined with a five-axis machining center C 250.

Automation

Today at Hermle, some 30% of all machines delivered are equipped with automation systems. At the specialist, they expect an increase to 50% in the coming years. At EMO, the machine builder is presenting two automation solutions. For example, the HS flex handling system will be coupled with the five-axis machining center C 400 from the Performance Line. This modular HS flex can be expanded to a multi-pallet system with several storage modules and an additional element. This HS flex is controlled and managed by the convenient HACS (Hermle-Automation-Control-System), which optimizes flexibility and user-friendliness. Hermle also highlights the compact and modular robot system RS 05-2 with a floor space of only 2 m². A great deal of attention was paid to the loading of raw parts: from a single die holder, a Kanban storage and a drawer storage to a pallet storage. This robotic system can be combined with five machining centers from the Hermle range (C 250, C 400, C 12, C 22 and C 32).

HIMS is one of many digital building blocks on the road to the smart factory and Industry 4.0.

Cross-pollination

The Hermle systems can also be found at some tool manufacturers. For example, YG-1 (booth H06 in Hall 3) uses the C 650 and EmugeFranken (booth F16 in Hall 4) presents its tools on a C 42 U dynamic.