Software in the metal industry - from nice to must-have

2025: new round, new opportunities? Obviously, this is up to the metal industry itself, but the opportunities to tackle some persistent challenges are available thanks to modern software. Sharing data more easily, capturing knowledge and automating operations are central to this.

Those who think of automation quickly see robots and smart control software passing by in their minds. AI is also a frequently mentioned trend. But as the article in Metaalvak in Fall 2024 also made clear, there is sometimes also a clear difference between what experts say is important and the choices companies make. Responding to staff shortages was considered more important by several companies than fully committing to AI and cybersecurity.

Digitize knowledge, automate actions

What is clear is that almost everyone now sees the potential of modern software tools. A growing number of companies are investing in software to lay a good foundation and be able to respond more efficiently and flexibly to critical customers, staff shortages and competition. One way to work smarter and more efficiently is to digitize data and knowledge and use it to automate operations. This is especially true for companies where the number of orders and transactions is large or growing rapidly.

'Don't be afraid, but look for value'

Jochem Swierstra, business consultant at ERP vendor Prodin, still sees a lot of duplicate data entry at companies. "That's killing efficiency. And there are a lot of good systems for working smarter, including ERP, but also manufacturing execution systems (MES). With these you can communicate with the production line or register measurement data. Many specialized software can also be integrated with other systems, such as ERP. And all those applications provide more control of and confirmation for the employee. I would advise companies not to be afraid of using multiple tools, but to look primarily at the value they can provide. Business demands are rapidly increasing, such as the use of mobile devices and apps. In addition, everything needs to work in an integrated way as much as possible."

Remote programming

Working without software, as for controlling machines, is almost unthinkable today. In practice, software controls lathes and employees can read and write with those machines. Swierstra: "Companies are often happy with the old custom software, but try finding developers for those old tools. Making choices about what you do and don't need can be difficult, but you will have to learn about the capabilities of modern software. If only because you have a problem if support stops or your IT expert leaves." Modern software allows users to do programming remotely, offline, so machines can keep running.

Workforce shortage causes acceleration

Keizers Metaal is a company that attaches great importance to its own people, but sees software as indispensable in the modernization drive. Bart Tielbeek, automation project manager: "Automation should simplify daily processes, such as work preparation, and help perform simple tasks more accurately and consistently." According to Tielbeek, the staff shortage has accelerated the search for smart software tools.

The new portal, One Click Steel, is one of these tools. "A customer no longer wants to wait a week for a quotation. When a customer requests a quote, he also requests it from three other parties. Speed is an important factor."

Putting composition in portal

In the new portal, customers immediately see the options, price and delivery time. If something is not feasible, Keizers Metaal immediately gives a warning via built-in checks. Tielbeek: "We can also adjust small errors manually, so the client doesn't have to adjust and send everything all over again. Clients can easily place entire assemblies with sheet and tube laser work in the portal. We make sure behind the scenes that we as DG Steel Group complete an order with four companies." The metals company says it can initiate about eighty percent of production from the portal without human intervention. "Of course, a final check does take place. If all signals are green, then production can start."

Searching for improvement steps

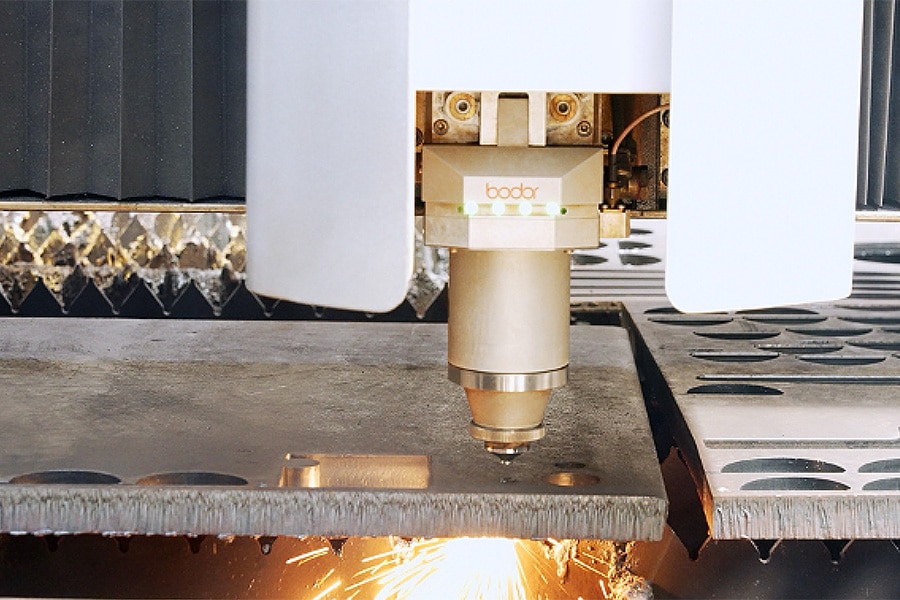

Sander van Doesburg, sales engineer at software vendor AESC, finds that companies don't always realize how big a challenge can be. "That insight only arises when we work with a business owner to map out how they operate and what improvement steps are possible. However, we have to demonstrate why a change makes sense, especially in companies that have been working the same way for 20 years," he explains. The impact of automation can be impressive, Van Doesburg emphasizes. "One of our customers, Ter Horst MetaalTechniek, had the goal of achieving the highest possible production capacity with as few employees as possible. They have several lasers, a number of press brakes and soon a tube laser will be added. Yet all these machines are controlled by just two people from work preparation."

Establishing professional knowledge

The greatest added value of software, according to Van Doesburg, currently lies in capturing knowledge and improving efficiency. "When professionals leave the company, you want to prevent their knowledge from being lost. This requires a combination of professional knowledge, some IT expertise and the vision of the owner of the company. Once that foundation is in place, you can analyze the business processes and see where efficiencies and time savings can be made. Finally, I recommend keeping the number of different vendors limited. This makes management a lot easier and more efficient."