Smart clamping devices and gripper systems for machining

The EMO proves itself every edition as the high mass of machining. The ideal place and opportunity to track trends. "Smart loading, smart processing, smart networking - these three core themes will characterize industrial production over the next five years," states Henrik A. Schunk looking ahead to the upcoming edition. "The core goal is smart simplification of industrial production." And SCHUNK has the appropriate products for that. You will find the clamping and gripping specialist in Hall 3, Booth D30.

While process stability and economic efficiency of the individual work stages have been the focus to date, modern applications will also make the process chain more flexible and provide detailed process data, according to SCHUNK experts. "Our clamping devices and gripper systems enable detailed monitoring of the production process in real time and independently perform the corresponding reactions," said the executive board member. The best example of this: the precision tool holder iTENDO with sensors, which will be available for trial applications starting this fall. It allows full status monitoring and documentation of process stability, as well as unmanned monitoring of limit values, tool breakage detection and control in real-time rotational speed and feed rate. If the cutting becomes unstable, the integrated smart system intervenes immediately in real-time without the operator having to do anything: depending on the situation, the process is stopped, reduced to previously defined basic parameters, or adjusted until the cut returns to a stable range.

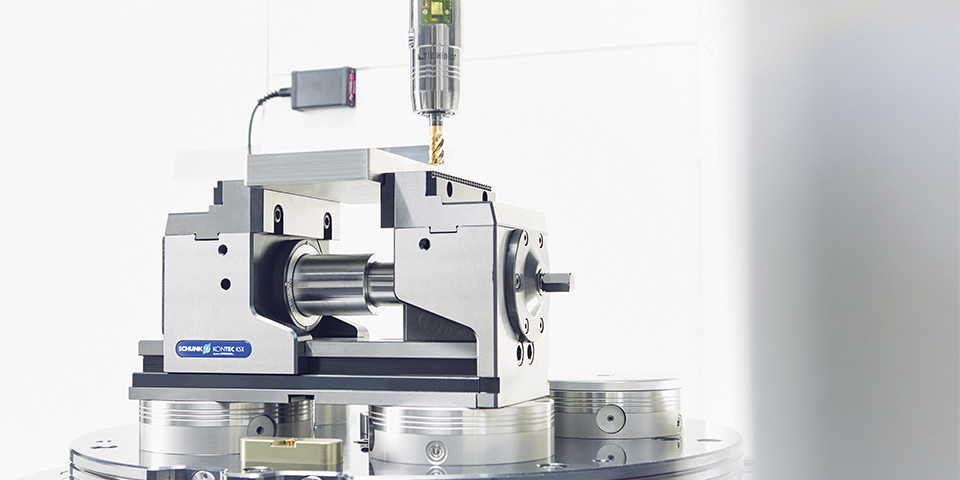

The smart iTENDO from SCHUNK enables real-time process monitoring and control directly at the tool level. The geometric and performance data of the toolholders remain unchanged even with sensors.

Focus on automated loading of machines

SCHUNK is introducing for the first time in the VERO-S quick-change pallet system a sensory quick-change pallet module that enables permanent monitoring of the downward traction force, the position of the clamping carriage and the presence of workpieces or pallets. In addition, new special VERO-S components will be presented for aerospace, 3D printing and direct workpiece clamping. On top of these highlights, SCHUNK will draw special attention to advanced concepts for automatic machine loading - from simple and cost-effective supporting automation solutions and applications with lightweight robots, to convenient palletizing solutions for flexible production of small series and ergonomic, collaborative solutions with the long-stroke EGL-C gripper.