Machine technology on the cutting edge

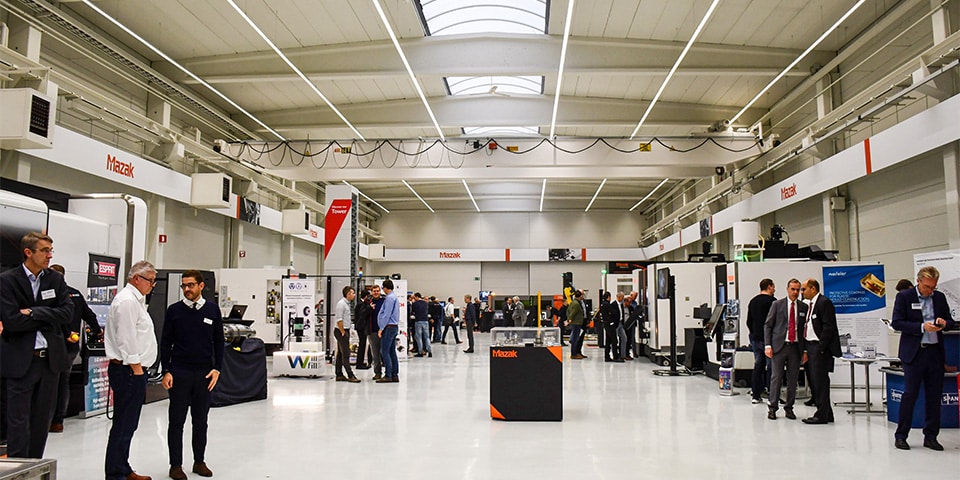

It was busy again in Leuven. As usual, Yamazaki Mazak's Open House days cast themselves as true attractions. Reason enough. The 750 visitors could discover the newest five-axle machine in the portfolio: CVS-500. The Integrex i-500 was also a Benelux first. Notable was the interest in the 4.0 connectivity corner, where Mazak showed smart solutions for monitoring, remote diagnosis and faster programming. But the strength of the event lies equally in the presence of automation and tool partners. Visitors were thus brought up to date on all developments in the market at once.

Straight from the EMO to the showroom of Yamazaki Mazak's European headquarters in Leuven. It is the route taken by the CVS-500. This newcomer to the range may call itself the perfect stepping stone to five-axis machining. It guarantees a very rigid structure that allows machining at high precision. With a spindle of 12,000 min-1 or optional 18,000 min-1 it is also clearly designed for speed. This is reinforced in these times of high mix, low volume production by the ATC tool magazine that accommodates thirty tools for quick changes (1.3 s tool-to-tool).

Newest and largest member of Integrex i series

Across the showroom, the newest version and immediately the largest member of Mazak's industry-leading Integrex i series caught the eye. It could be seen live at work for the first time in the Benelux countries. This machine features extra bed length for machining complex workpieces. The advantage? Less interference between the turning and milling heads. The Integrex i-500 is equipped with a main spindle with high power and high torque and with the newly developed compact milling spindle head, which provides a larger machining area. Because all machine components are designed with maximum rigidity and thanks to the high-precision measuring scales used as standard for the B and C axes, high accuracy is guaranteed.

Some atmospheric images from at Yamazaki Mazak's Open House.

4.0 connectivity

Productivity today, however, is about more than just excellent machines. Digitalization has taken hold. No longer just in sales pitches, Mazak's customers have meanwhile moved toward smarter production. In the 4.0 connectivity corner, the various solutions were brought together. A corner where it was constantly busy, by the way. Many metalworkers today do not have insight into their production. Therefore, Mazak has developed simple software solutions and the new Smooth AI control to monitor production, apply remote diagnostics or introduce digital twins and AI. This brings quick insight into where improvements can be made for cost and time savings or quality injections.

Manless manufacturing

After all, automation will be the key word in the workplace in the years to come. That's why Mazak also insists on inviting a number of automation specialists to its Open House. This year, among others, RoboJob was present. They had brought their RoboJob Tower Advanced. This universal concept serves to allow machines to operate unmanned for longer periods of time. In addition to loading and unloading pallets, the robot can change grippers or collets. Indeed, there is space provided in the warehouse for all necessary fixtures and tools. This allows your CNC machine to continue working manless for even several days.

Setting measuring tools accurately

For tools, the Hoffmann Group signed on present. They also provided some seminars at the event. One of the products highlighted there was the GARANT Setting Bench SB1. This easy-to-use device allows measuring tools to be set quickly and accurately. Those who do this the traditional way will spend the necessary time doing so, especially when deviating sizes are used. Now you only need to enter the values via the touchscreen. The high-precision motor control adjusts the preset values in real time, even if different measuring forces are applied. Favorites can be saved for repeated setting of measuring tools.