Extensive automation ensures very high spindle efficiency

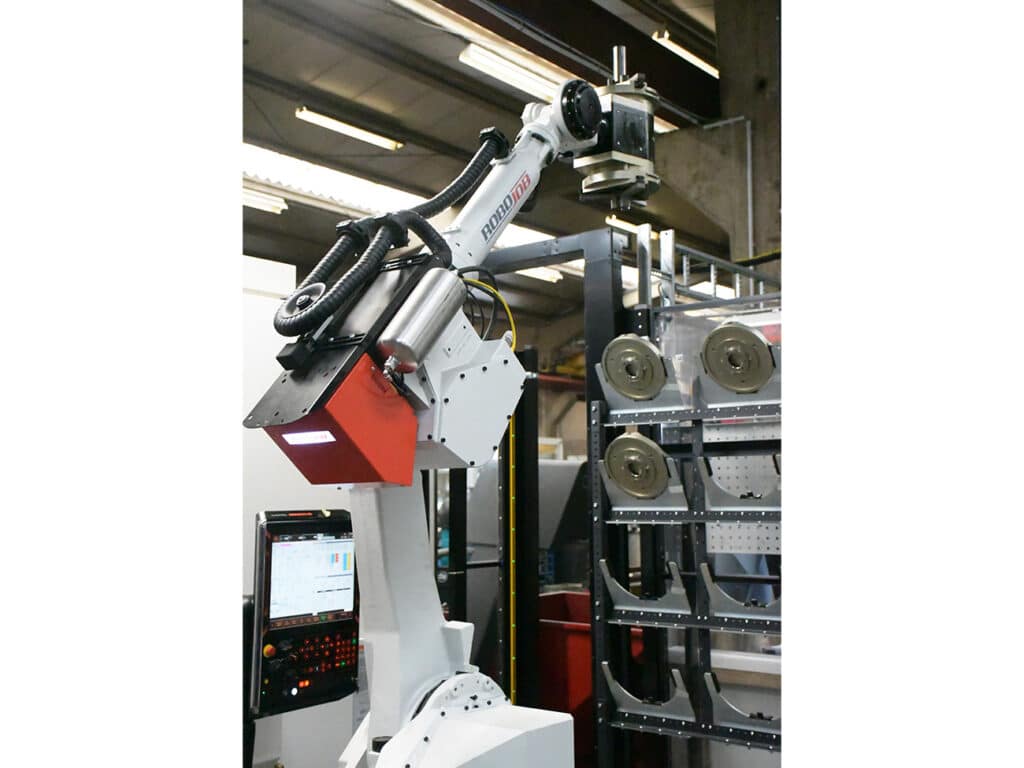

The answer lies in pervasive automation. No sooner said than done. The Integrex J-200S with RoboJob Tower and automatic claw change, a first for the Benelux, was the first step in his master plan.

Pieter Cappoen took over the Poperinge company Platteau seven years ago. A case of entrepreneurial blood itching irresistibly. "I knew the company from before: I still did vacation jobs here and always kept in touch with the managers. When they had no successor themselves, this business was an excellent starting point for me. I knew from my own experience that the basics were right." It was the beginning of a story of investing. "Initially, I wanted to expand the machinery to deliver larger pieces. There is increasing demand for this, but the number of suppliers still remains relatively limited. First it went up to 5 m, then followed by a machine up to 7.5 m and then up to 11.5 m. Each time machines from the same manufacturer, to facilitate interchangeability of programs, tools and operators. If we want to go even bigger, a new production hall will have to be built for it." Space that Platteau does still have available. The company can still double on its current site.

Automation of smaller workpieces

But first, Cappoen wanted to invest in the smaller work. "To be able to offer our customers the full spectrum. Admittedly, competition plays much harder in this segment, both from home and abroad. Automation is therefore more of a necessity than a luxury to be able to do that in an economically profitable way." Cappoen had the opportunity to visit Mazak in Japan in 2018. There, his vision of an in-house man-poor production took full shape. "I talked a lot with those people and saw how they too deal with the scarcity of technical personnel. By focusing on extensive automation, I can run one shift with operators during the day. They handle the more complex work and take care of setting up and programming the work at night. Then it's up to the robot to get the machines to make chips for 16 hours. For me, that's the way to machine smaller pieces."

Integrex chosen for versatility and reliability

The first investment to realize its goal was the Integrex J-200S equipped with automation in the form of a RoboJob Tower. The unique feature of this installation is that the robot can change both workpieces and claws. This was done in cooperation with SMW Autoblok. The installation early this year was a first for the Benelux. "An extra dose of flexibility," Cappoen clarifies the choice. "With the 45 claw sets and the 72 tools in the Integrex, products can be changed autonomously all night long." That this solution just has an Integrex at its heart was clear to Cappoen from the start. "I had to have one standing there. They are reliable and versatile machines thanks to the large tool magazine and offer a first stepping stone with their 4 + 1 axes to more complex five-axis work. 95% of the pieces come off the machine perfectly finished. Moreover, the machine has all the capabilities to track them remotely. An asset for me to continue producing even on weekends."

Immediately a second order

The solution convinced immediately. "The machine is flexible, precise, user-friendly and ergonomic because you are close to the pieces. On weekends, I already get to performances of 50 h. of production in one piece. As we get to grips with them even better, we can increase this further. The operators have welcomed this piece of high-tech with open arms. They love working with high-tech. I immediately noticed that I can set my prices a lot more competitively because of this thorough automation. You can just see that it works." Less than six months later, an order followed for a second, identical machine from Mazak. "Again to create that interchangeability, but this time with a barfeeder as an automation solution. Especially for finishing pieces with a diameter of 15 to 65 mm, this automation solution has an edge. The intention is to eventually install a second Tower alongside it. Together, they can then produce the range from 15 to 200 mm in diameter fully automatically. You don't actually need many machines to produce smartly, but you do need a thorough automation solution. That way you can keep producing."