Basic knowledge prerequisite for a beautiful weld

Good personnel is scarce, and well-trained technical personnel seem to be a rarity. This is doubly true for welders, a profession with incredible things to do, but which requires a good deal of skill. You have to smell, feel and know what you're doing, and that starts with a thorough basic knowledge of welding technology. Only when that is in place can Industrie 4.0 technology make the difference in achieving higher quality and productivity in welding.

The call for good welders is something of all times. Industry has always been shy of qualified welders. The basics that were sinned against 20 years ago are still the same as they are today. Yet the scarcity of skilled welders seems greater than ever. Young people are turning their noses up at the profession and, for lack of interest, a number of schools have also closed their welding schools. Basic knowledge is starting to fall short. So a negative spiral that seems difficult to break, just when the industry is doing well and technical personnel are "in hot demand. What's going on?

In any case, virtual welding shows that welding technology is keeping up with the times and using all modern gadgets to make the welder's life more enjoyable.

Towards a healthier, safer, hipper image

The profession still carries the same "dirty" image as before, and that certainly doesn't do the influx any favors. Spatter, smoke ... there is no way around it. These are peculiarities of the welding process. Yet today we are much further ahead than a few decades ago. Technology such as spot extraction on the welding torch and welding helmets offer the necessary protection. Welders no longer have to spend their days in dark, smoky environments. That may need to be highlighted more clearly. Teach them to work with such protection technology so that it is actually utilized in practice and does not collect dust in a closet. Welding torches with spot extraction, for example, may not be as comfortable to handle because of their volume and weight. If you welder doesn't want to use it, see if spatial extraction is an alternative. Or teach him how to use it so he can work safely. Another evolution that could benefit the image is virtual welding. This could help, for example, to get young people interested in welding training. In any case, it shows that welding technology has moved with the times and uses all modern gadgets to make the welder's life more pleasant. A good introduction, for sure. But don't forget to introduce virtual welders to the real deal at the same time. So that they don't get a big scare when they first enter a real working environment and feel the heat radiating from the workpiece.

Teach young welders to work with protective techno-logy such as spot extraction so that it is actually utilized in practice and does not collect dust in a closet. (Image: Photo Studio Wiegand)

Taking control of basic techniques training yourself

Companies should not look only to training institutions and schools to train young people to become skilled welders. By providing their own training, unless from older experienced welders in the company who pass on the tricks of the trade, unless from manufacturers who specialize in specific techniques, they themselves can be part of the solution. The same goes for manufacturers. To give the right advice, a salesperson must also know their stuff. The basic techniques have to be hammered on and mastered. The fact that entrepreneurs are afraid that they will pay for training and then another company will profit from it should not be an excuse. The need is pressing enough to seek out just those candidates with the right growth potential who are willing to learn. Also, remember that technology does not stand still. The welding materials change, the gas composition, the devices ... Just because a welder has a way of working that has worked for years does not mean that it is therefore the best, the most efficient. So try to get your existing personnel excited about training as well. Try to challenge them to get the full efficiency out of a piece of equipment or an application. A good example is purple tungsten electrodes. Both in terms of efficiency and safety (radioactivity), they represented a step forward from the theorized variant, which is already banned in the Netherlands. Still, it took many efforts by manufacturers to convince welding Belgium of this.

Just because a welder has a way of doing things that has worked for years does not mean it is the best, the most efficient. Try to get your existing staff excited about training as well. Image: Michal Rojek)

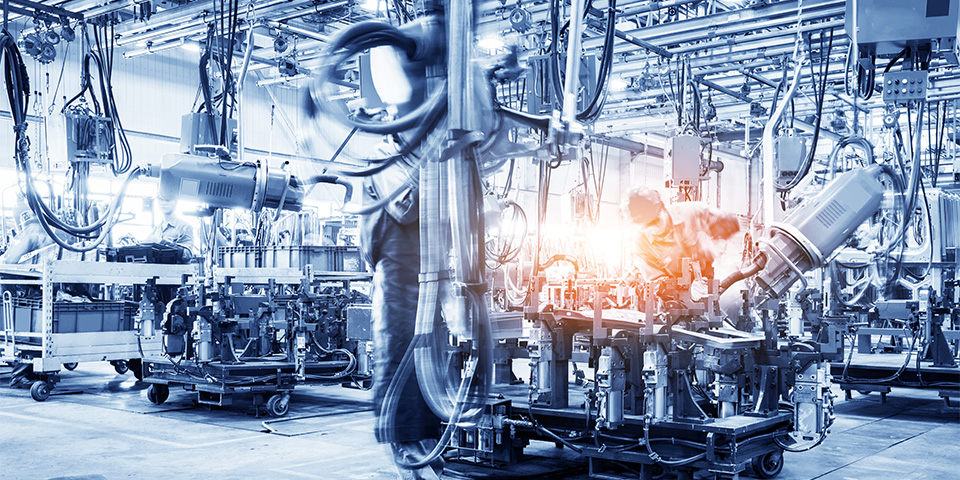

Only then look at high-tech gadgets

Only when those basic techniques are mastered will you benefit from looking at modern technology. But beware not every new gadget will bring you the returns you want. The panacea to completely replace human expertise has not yet been invented. Everything starts with technical knowledge, because welding is and always will be an interplay of physics and chemistry to achieve new structures and surfaces. So try to see through the hype and investigate where exactly the added value for your production process lies. Cobot technology, for example, can be particularly interesting to make automation pay off for smaller series work (say, 200 to 300 pieces). Programming can be done a lot more intuitively than with the classic robot, but that still means that you have to teach the cobot how to weld your product. And that your application must be intrinsically safe, as welding involves the necessary safety risks. For every hazard there is a solution, but they come at a price, which will reduce its price advantage over robots.

The panacea to completely replace human expertise has not yet been invented. Everything starts with technical knowledge, because welding is and will remain an interplay of physics and chemistry to achieve new structures and surfaces.