Automation of welding processes in fingers

Welding is a profession in its own right. To provide customers with the best possible support in welding, AW Tech guarantees high-quality professional equipment and service. Customers are supported in word and deed, also in automation projects. Because with the scarcity of good welders, automating welding operations is becoming more interesting than ever. AW Tech relies on Schnelldorfer's seam and longitudinal welding machines for this. To automate plasma cutting, one can then rely on the devices from Elettro.

AW Tech always has a welding-ready solution in house for its customers. It has done so from Verbrandhofstraat in Roeselare since 2011. "Service. Service. Service. That's what it's all about for us," opens manager Stefaan Gevaert. "On the one hand with a wide range of good material. The suppliers we carry in the range have been the same for years. Just because their solutions prove themselves daily in practice with our customers. A nice recent example is the Titan XQ pulse compact from EWM which are an ideal addition for welding booths, craft welding and training. On the other hand, we are ready with advice and our team is on standby for service interventions. Finding technically skilled welders today is no easy task. That makes providing support and solutions more important than ever."

The Elena One series was designed specifically for longitudinal TIG welding of thin-walled sheet metals.

Only to strain

For this reason, automation is clearly on the rise in the metal industry. AW Tech has been handling this for years. You can go there for Schnelldorfer's seam welding and longitudinal welding machines but also for the complete support of an automation project from A to Z. "The cooperation with Schnell- dorfer for the automatic welding of clamped pieces goes back many years," Gevaert indicates. "One then actually no longer needs a welder, one only needs to clamp. Based on the material and sheet thickness, the correct welding parameters are set and the machine goes to work. Schnelldorfer's devices guarantee a perfect finish that completely meets the customer's needs. It always works."

Cost-effective solutions for seam welding and longitudinal seam welding

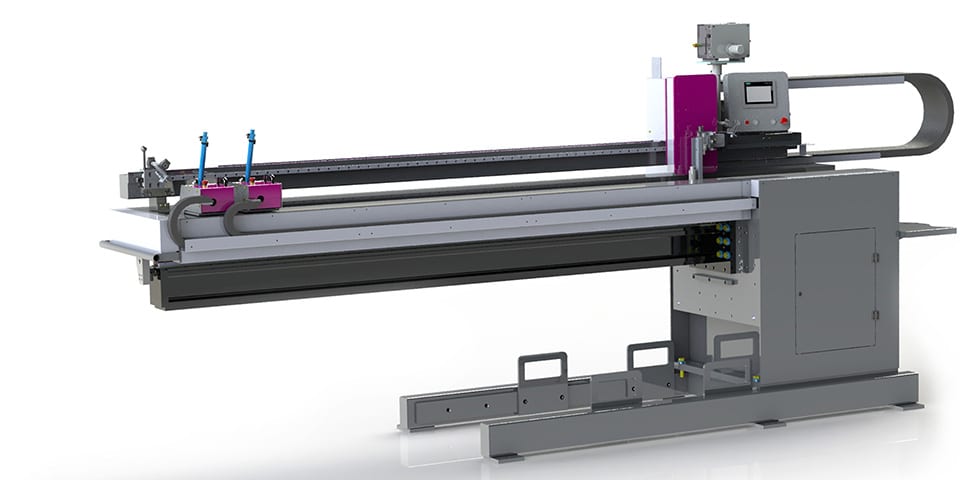

The Linearweld machine series represents the top in longitudinal welding. It can handle long welding lengths from 2,100 mm upwards and is designed for the highest loads. The clamping system features adjustable jaws and an automatic spindle lock. The modular design makes this a cost-effective solution, which also has virtually no distortion in the welded parts. In addition, there are the Elena One longitudinal seam machines. This series was designed specifically for longitudinal TIG welding of thin-walled sheet metals. Again, only minimal deformation of the welded pieces thanks to the high-quality technology at the heart of the machines. The more complex TIG welding is thus transformed into an easy operation.

A great example is the Plasma 1050 LCD inverter, a compact, three-phase powerhouse that is suitable for heavy-duty work and excels at cutting plates between 32 and 38 mm thick.

Automating plasma cutting

There are also opportunities for automation for plasma cutting. "With the plasma cutting machines from Italian company Elettro, we can provide a manual plasma cutting source or place them on an automatic table," Gevaert clarified. "A good example is the Plasma 1050 LCD inverter, a compact, three-phase powerhouse that is suitable for heavy-duty work and excels at cutting sheets between 32 and 38 mm thick. But it also delivers beautiful cuts in thinner and thicker material thanks to its Ultra Cut Capacity and Innovative Thin Cut technology, respectively. The device guarantees high cutting efficiency and optimum surface quality." The optional CNC interface means that the cutting signal can also be controlled with an automatic CNC bench.