Automating your grinding process, where do you start?

Where do you start if you want to optimize your automatic sharpening process? What factors come into play and and how do you make the right choices?

** Come to our customer day on automating your production process! Which will be held in April 2024, in cooperation with 3M, TFT (cobot applications) and SLH (robot applications). Stay tuned and get more information by leaving your details on our special Web page on automating.

The first question we ask when optimizing your automatic sanding and grinding process is: What is a given in your situation (capabilities of the machine, for example) and what are variables? That is the starting point with which we will achieve an optimal result. We measure that result in time, because that is the most precious part in the whole process.

The most important question is: which sanding belt is going to make money for you?

With any tire from expensive to cheap, you can generally achieve the desired finish. But cheap and expensive are only relative terms. The question is which sanding belt will make money for you. Because it reduces the number of steps in the process or still performs well with a higher throughput or has a long tool life. All of these mentioned have the great advantage of saving time. And time is much more precious than the purchase price of a sanding belt.

As a general rule, the more pressure you can apply, the faster you can work.

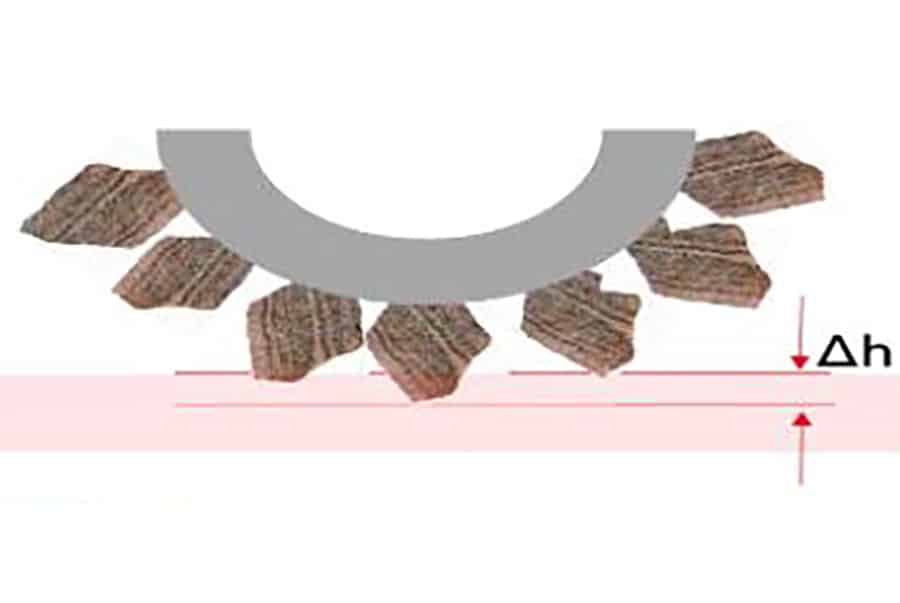

The maximum pressure you can apply usually determines how fast you can work. As a rule, the more pressure you can apply, the faster you can work. Therefore, the hardness and profile of a contact wheel on a broadband is also important. With a hard contact wheel you generate more pressure, just as a wheel with grooves gives more pressure due to surface reduction of the contact point.

We list below four more parameters that affect your speed of grinding, each time the pressure is a determining factor. So always keep a close eye on this parameter, its influence on the other variables is huge!

Three more parameters that matter on the removal rate of a sanding belt:

1. Belt speed

If an abrasive grain cuts easily through the metal, it takes relatively little time to do its job. The throughput can be increased, allowing for faster work.

What is essential here is that the abrasive grit is sufficiently print gets and has enough contact time with the metal to break out so that a new sharp edge is created and the tire can continue to perform. (Regeneration)

Belt speed recommendation

| Calibration and heavy machining | Polishing Finishers | |

| Steel | 30-36m/s | 25-35m/s |

| STAINLESS STEEL | 30-36m/s | 25-35m/s |

| Nickel alloys | 30-43m/s | 25-35m/s |

| Aluminum | 20-25m/s | 20-25m/s |

| Titanium | 14-17m/s | 10-15m/s |

2. Throughput (broadband) or power/step-over (longband).

The higher the feed, the faster work is done.Again, enough contact time between abrasive and metal and enough abrasive-mineral print gets to regenerate. Only then will a tire stay sharp. How quickly or easily a grain breaks out depends on the mineral. Each mineral has its unique properties in this. If the grain cannot break out, it will round off and start to glaze. This renders the bond worthless. So match grain and speed.

3. Construction of sanding belt

Sanding belt with linen backing

A sanding belt with a linen or polyester backing has a longer life but is also more expensive than one with a paper backing. A linen backing is used if you have a lot of repetitive work. This creates even wear and prevents rutting. You can use up the tape completely.

A linen spine is less likely to tear than a paper spine. Can you get a lot of print give, choose a band with a linen backing and a ceramic grit. This works by far the fastest. Therefore, although the purchase price is higher, you will still save money with this band.

Sanding belt with paper backing

A sanding belt with a paper backing is often much cheaper and certainly has merit. You use this belt when you have many different products to work on. All these different models cause a diverse wear pattern on the belt, resulting in an uneven grinding pattern. This is often undesirable and therefore a tire is sometimes replaced prematurely. Then it is nice that the tire is not very expensive.

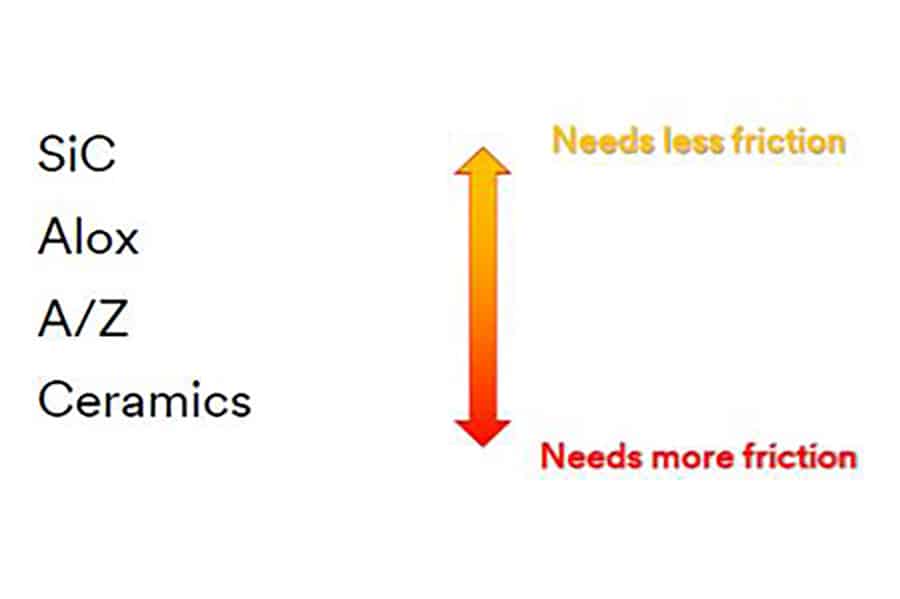

If you are not able to apply much pressure in your situation, then a paper tape with a simple Aluminum Oxide grain may be the best solution. The grain breaks despite the lower print yet looks good and performs well under the given conditions.

Mineral and grain size

In addition to the tire backing, the type of mineral and grain size play another important role. Each mineral has a "sweet-spot": the optimal conditions under which they perform as fast and as long as possible. This sweet-spot is determined by the print and by type, shape and size of grain.

4.Stand time

Stand time is also of great influence with these long and wide tires because changing the tires is often a time-consuming job, interrupting the production process. The fewer changes the better.

Other important factors

Heat input

The application of widebands and longbands is often on thin plate material. What is important here is that not too much heat is introduced to prevent deformation of the plate. If the plate gets too hot there are several options, depending on your own situation you make a choice from the different options.

- Speed of the sanding belt or feed rate down. This increases the contact moment of the abrasive grain with the metal.

- Sharp grains cut into the material more than they rub and polish. They chip more and introduce less heat.

- This principle also applies to the difference between a coarse and a finer grain. A finer grain produces more friction and thus also introduces more heat. After all, there are more contact points for the same surface area.

- By playing with bandwidth and throughput, you affect heat generation.

With this article, we hope to give you some insight into the factors involved in how sanding belts work and how to optimize your sanding process. As you have already understood, there are no firm statements about which belt works best on which metal. The power of the machine plays a big role, the contact wheel, the material to be worked on and the desired finish. We can't possibly go over all the scenarios in this blog. But we'd be happy to visit you to provide customized advice.

In this, speed is the determining factor. We make this clear with a calculation example:

Cost of machine + setup + belt + material consumption = € 150 per hour

Working 30% faster will save you €45 per hour that's €360 per day.

Webinar on automatic deburring:

Watch our webinar we created in conjunction with Q-fin. Grinding Power and the right consumables together ensure the optimal result. What factors are important and how you can influence the end result, you will learn in this webinar.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Metaaltechniek Handelsonderneming BV.

Contact opnemen

Contact opnemen