Clean cutting surface without rework thanks to 3D water jet cutting machine

Those who can perform all steps of the process in-house are not dependent on other firms for planning. Deconinck-Wanson of Gavere has specialized in the construction, maintenance and repair of industrial burners and (steam) boilers for more than 35 years. To respond even more flexibly to the demands of partners and customers, the company recently invested in a 3D waterjet- cutting machine. After thorough evaluation of the systems on the market, manager Geert Deconinck and his team chose the quality of the Austrian brand STM in combination with the service of distributor The Tollenaere.

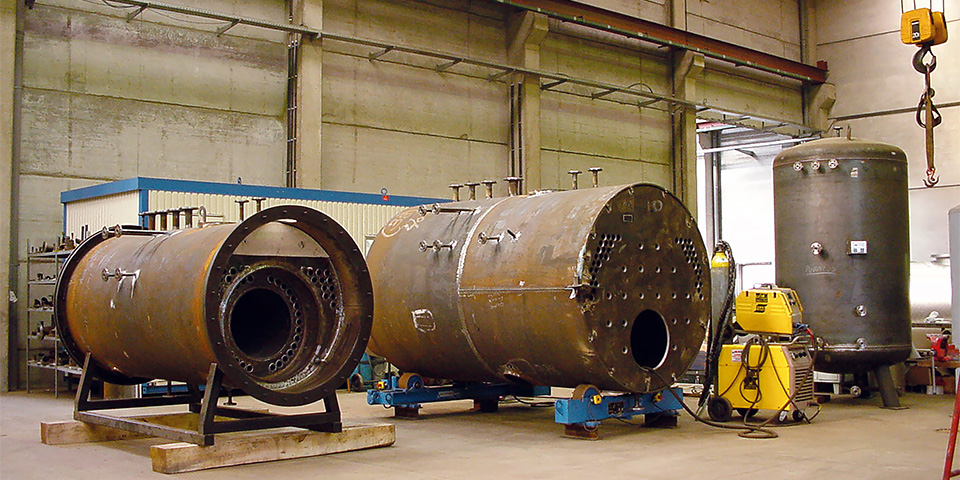

Deconinck, founded in 1982, was originally active in the maintenance and repair of industrial burners and boilers. Soon the focus also turned to the construction of industrial steam boilers, the elaboration of turnkey projects and the rental of mobile installations. "Today we are a supplier of Steambloc® steam boilers, Vaporax® steam generators and Thermopack® thermal oil boilers. We take care of the complete package from engineering over construction, installation and start-up to after-sales service," says managing director Geert Deconinck. "All products and installations are always adapted to the specific needs of the customers and all boilers are inspected and certified by a recognized inspection body that guarantees quality and safety."

Thanks to the STM waterjet cutting machine, Deconinck-Wanson can now perform all cutting work even more efficiently, significantly increasing flexibility.

Waterjet cutting technology from STM

The manager continues to invest in the further expansion of the company. Thus, the activities and machines of Wanson Industrie from Tienen were taken over and the company built a new production hall in Gavere. Updates to the machinery and automation of operations are preparing the family business for the third generation, which is currently settling in. Recently, an older gas-fired plant was replaced with a high-performance cutting machine. After a thorough evaluation of the various technologies and systems on the market, Deconinck and his team chose a waterjet cutting machine type WS 4020 PremiumCut 3D from STM. "This high-tech Austrian five-axis waterjet can cut steel, stainless steel, aluminum, stone and glass, as well as all types of rubber," explains Gerrit De Vos, representative at distributor The Tollenaere adds. "The cutting surface, consisting of slats, can support a weight of up to 1,500 kg/m². The rotating 3D cutting head with automatic height control can be positioned at an angle of up to 68° and rotate endlessly in any position, without the height guides getting in the way." This system comes with a waterjet controller equipped with a control panel and 20" monitor, as well as the cutting software, a low-noise high-pressure pump and high-pressure lines for the connection between pump and machine.

Confidence in a partnership with De Tollenaere

The waterjet at Deconick-Wanson is running at full speed. "We chose this machine primarily for its clean cutting surface, which eliminates the need for post-processing. It is used today for the production of our own products, but also for third-party orders," Deconinck concludes. "It is our first STM machine on the shop floor, but so far we are very impressed with its performance. The strengths of The Tollenaere were well known, as they have already installed machines at our site. Once again, we could count on their knowledge to suggest a suitable machine. Moreover, we can always call on the know-how and support of their team in case of any technical questions or problems."