New bowl brushes optimize finish quality and lead time

To offer customers the highest quality while remaining competitive, automation is often a must. Even the final machining of their customers' mechanical parts is done automatically at Aluro CNC with GARANT bowl brushes from the tool specialist Hoffmann Group.

Aluro CNC has been the reference for manufacturing high quality mechanical parts for more than thirty years. The machining company from Heist-op-den-Berg supplies components and machine parts for clients in such diverse markets as medical, aerospace, food and mechanical engineering.

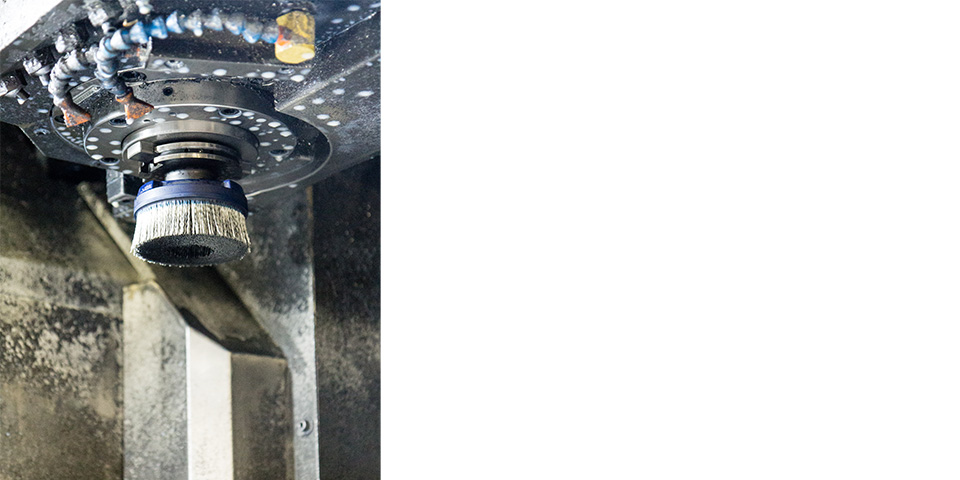

GARANT bowl brushes for CNC machines or robotic cells are used to rework workpieces automatically, quickly and efficiently after the machining process.

Strong focus on automation

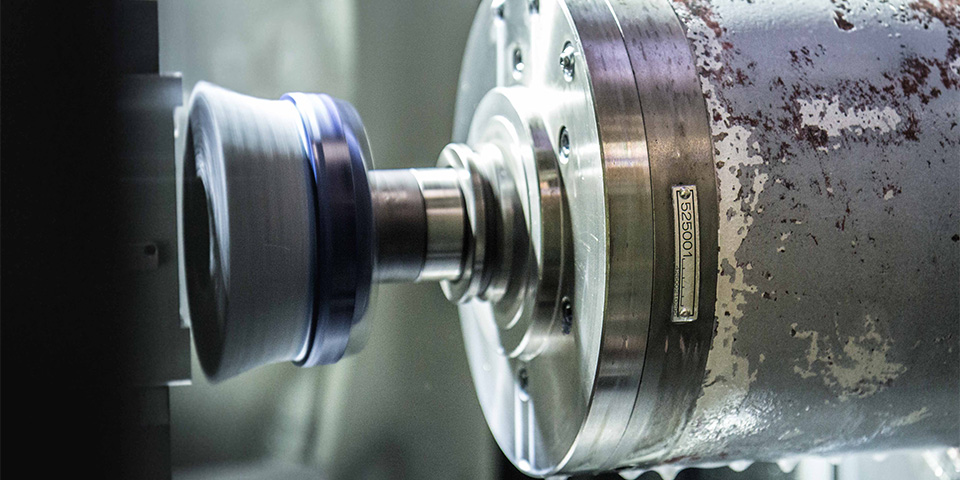

In addition to about thirty employees, Aluro CNC has a highly automated machine park, to which the link with sister company RoboJob is no stranger. They develop solutions for the automatic loading and unloading of CNC turning and milling machines. "Automation is very important to Aluro for several reasons," says technical manager Pascal Van De Sande. "There is an acute shortage of the right technical personnel in Belgium. Automation is the perfect solution for this. It allows us to reduce not only our labor costs, but also the prices for our customers. It also allows us to produce day and night and achieve a better flow of products. Automation provides us with a huge competitive advantage." Aluro CNC is an established and valued name in the market and is known for the quality of their delivered pieces. Moreover, they are able to manufacture very complex and specific components and provide detailed measurement reports which are very important especially in the aerospace sector.

GARANT cup brushes eliminate manual rework

In its quest for continuous optimization, Aluro CNC stumbled upon Hoffmann Group. As a leading provider of quality tools, operating equipment and personal protective equipment, this German specialist launched the GARANT bowl brush range last year. These high-tech brushes for CNC machines or robotic cells are used to rework workpieces automatically, quickly and efficiently after the machining process. "The main application of GARANT bowl brushes is precise deburring, rounding of cutting edges and optimizing the surface finish of precision parts," explains Dominique Van Lunter, technical specialist in machining at Hoffmann Group. "The bowl brushes are ideal for cleaning and finishing large surfaces and complex parts without changing the geometry of the workpiece."

Bowl brushes are ideal for cleaning and finishing large surfaces and complex parts without changing the geometry of the workpiece.

Constant finishing quality, faster turnaround time

Several Aluro CNC machines were already equipped with bowl brushes from another manufacturer. "However, we were not achieving the desired results with these," says Van De Sande. "Therefore, we decided to carry out some tests internally with the GARANT bowl brushes. After some searching and experimenting with the parameters, we were very satisfied with the final results of our pieces. Among other things, we produce large cast iron sheets that used to require a lot of manual deburring. With our new bowl brushes, the finishing work is now done fully automatically and we save a lot of man hours. Moreover, they guarantee constant finishing quality. You only have to program the machine once and the finish is identical for each workpiece. The fact that the turnaround time for our workpieces has also become a lot shorter is a nice bonus!"