New steering combines best of both worlds for huge time savings

Each specific bottle requires a specific size part. That is what Macovak has made its specialty. With precision and service as its calling card, the Lint-based company has built itself a loyal customer base at home and abroad. But that requires modern machinery that excels in the cost-effective production of single pieces. To combine maximum speed and ease of use, Macovak therefore chose the XYZ SLX 425 lathe with ProtoTrak control. Crispyn Machines was responsible for the delivery.

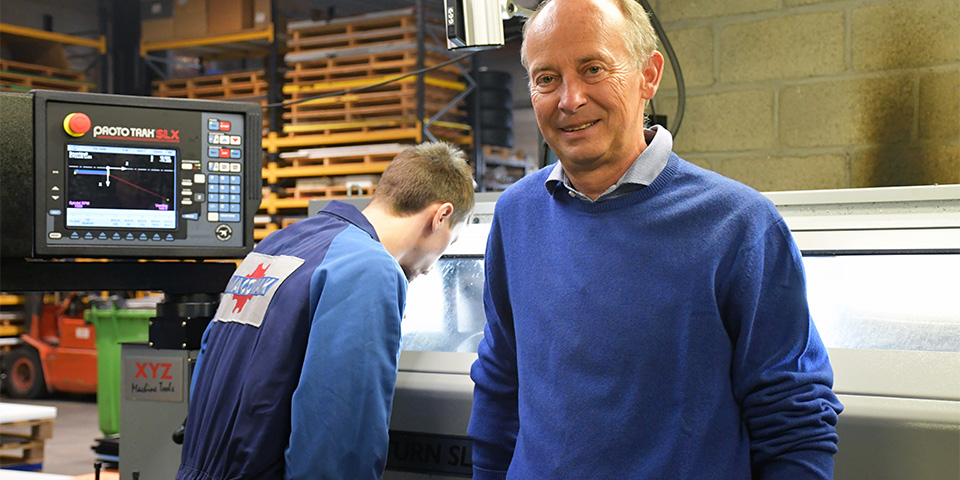

More than fifteen years ago, Macovak in Lint was born out of Didier Gillain's passion. The expertise and contacts he had built up in the beverage industry were used to start producing format components. Managing Director Didier Gillain: "Machines in bottling plants, for example, are equipped with format parts. They ensure extremely precise positioning of the bottle at the filler, the labeling machines, the shutter ... If you know the staggering speed at which bottles pass there (up to more than 60,000 per hour), it is clear how important this accuracy is. The volumes are so high that even the slightest slack can cause a huge price tag." Macovak is certainly not just in the food industry. Gillain: "Everywhere where liquids need to be filled, you can find our format parts. From small bottles for pharma, to 20-l drums in chemistry."

"You don't actually need any knowledge of G or M codes to turn beautiful pieces with this. Even I could do it," says case manager Didier Gillain with a wink.

Precision requires modern technology

The fact that Macovak also sells its format parts beyond our borders has everything to do with the expertise of the 10 employees working there. "Our business revolves around solving problems for customers. On the one hand with a fast reactivity, on the other with the knowledge to perfectly tailor the format parts every time." Macovak uses state-of-the-art technology for this purpose. "We go on site with a measuring arm to measure the machines and vials in 3D down to the smallest detail. After all, any adjustment in either can lead to too much slack. The next steps are also digitized so that we can eliminate errors. Based on the measurement, we draw out the format part in 3D. That is the most difficult step. From there, we then generate a program in the CAM package to start making it. Then it's up to our milling machines and lathes."

New lathe makes a difference

To also make a difference on the shop floor with accuracy and fast service, Macovak recently chose the XYZ SLX 425 lathe with ProtoTrak control. "The lathe we had was really in need of replacement. We now have two draftsmen who have to provide designs for three milling machines. Therefore, for the new lathe I really wanted a control that would give our operators all the possibilities to quickly and easily program or manually finish the workpieces at the machine itself. On a previous visit to Crispyn Machines' showroom, I had already had my eye on the ProtoTrak controller. So I knew where to go." Gillain did not go alone and took his operators with him. After a demo and sample in the showroom, they too were immediately convinced. "You don't actually need any knowledge of G or M codes to turn beautiful pieces with this. Even I could do it," Gillain says with a wink.

"What stands out is the time savings we are making. The period is still a little short to put a number on it, but it is noticeable."

Huge time savings

The XYZ SLX 425 lathe has been on the shop floor at Macovak since the beginning of this year. "What stands out is the time savings we are making. The period is still slightly short to put a number on it, but it is noticeable. Compared to conventional lathes, we can track certain curves or angles in a program for a faster finish. And relative to the CNC lathe, we find that little time is lost in programming. So the best of both worlds." After just one day of training at Crispyn Machines, Macovak's operators were already away with the controller. It has been running at full speed on the shop floor ever since. "That's the beauty of the simplicity of the ProtoTrak control. You can produce with it right away and in the meantime your operators are getting to grips with the machine even more. Within a few months, we then schedule another training session at Crispyn to really learn to utilize all the possibilities of the machine and the control."