Custom company counts on sawing machines that can't be broken

Everyone should have opportunities in the labor market. That is what Mariasteen in Gits since 1963 motivates to provide sustainable and rewarding employment to persons with disabilities. The metal department focuses primarily on more complex work. The sawing department not only delivers custom pieces for customers, but also operates the other metalworking machines from sawn material. Reliability is therefore the key word. Mariasteen therefore chooses band saws from Behringer and circular saws from Eisele.

The metal department in Mariasteen employs more than a hundred workers in two shifts. About 80% of them are custom workers. Industrial techniques coordinator Johan Jansens: "In traditional companies, the pace can be too fast for our people or they don't get enough opportunities to develop. We therefore do everything we can to make the work as workable as possible so that they can develop and, where possible, move on to the regular labor market." The subcontracting What Mariasteen excels at is the so-called more complex work. "By this we mean a piece of work that we can process from A to Z: sawing, bending, drilling, milling, welding and then even wiring and assembly."

Unbreakable

"Automation is a must, even as a custom company. To stay competitive, but also because we hardly find certain technical profiles, such as welder or forklift driver."

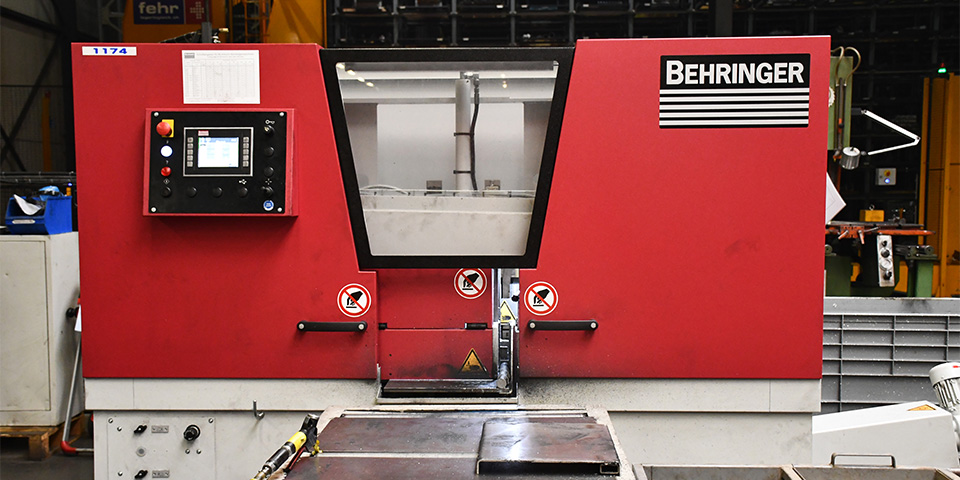

Currently, Mariasteen has 12 sawing machines, each connected to a fully automated long goods warehouse. "Automation is a must, even as a custom company. To stay competitive, but also because we hardly find certain technical profiles, such as welder or forklift driver." The sawing department occupies a prominent place within production. "The mother of all work here," Jansens says. The Behringer red immediately catches the eye on a tour. The partnership dates back to the 1980s. "The oldest Eisele still running production today has been here since 1990. We did another overhaul on it in 2016. Can't be broken," Jansens says with a wink.

Long warranty on spare parts

"Today we are due for an expansion. In order to handle larger pieces as well, the existing Eisele VAL350 is getting a bigger brother. Speed and accuracy are at the top of our wish list for the new circular saw. After all, we want to be able to keep measuring on the machine to a minimum. Therefore, we are looking for a circular saw machine that delivers the same accuracy from the first to the last piece in the series every time. In addition, we want a machine with a long service life, where spare parts are guaranteed for quite some time, because it will have quite a few years on the counter."

Strength, stability and speed

Mariasteen makes every effort to make the work as workable as possible so that custom workers can thrive and, where possible, advance into the regular labor market.

After exploring the market, Jansens' eye still fell on another Behringer - Eisele machine: the 20 kW VAL500E. "Other machines didn't have that power, that stability that we were looking for. When you go and take a look at their production, you understand where the difference lies. Thanks to the combination with servo technology, it will allow us to put down short cycle times. They are certainly not cheap machines, but if you calculate the cost per saw cut, then they will be fine", Jansens knows. He also shows enormous satisfaction with Promatt's service. "It is a dynamic company. Technical questions are dealt with quickly and thoroughly. And if intervention was needed, we always got very competent technicians on the floor."