Why invest in robotization?

Who today can easily find staff to operate their machine tools? Few entrepreneurs will be able to answer this question with a resounding yes. On the contrary, labor shortages often stand in the way of growth. The "war for talent" will make technical talent even scarcer in the coming years. So anyone who wants to grow will have to look at automation. An option that has also become interesting for every metal company today. Technological advances have greatly lowered the barriers to investing in robotization. This article attempts to talk the last doubts out of your head.

Automation lends itself only to standard products and large series. There is no greater misunderstanding in the metal industry that we are hereby trying to eliminate forever. All over the world, batch sizes are declining; "high mix, low volume" production is becoming the norm. A trend that robotic manufacturers and integrators have anticipated. In recent years, they have become more focused on the flexibility needed to handle a wider variety of products. Even down to single pieces.

To lower that threshold, for example, the complexity of programming was significantly reduced. Thus, you do not need to employ a robot programmer to automatically load and unload your CNC machines. With proper training, you can have your robots working an extra shift in the evening or at the weekend in no time.

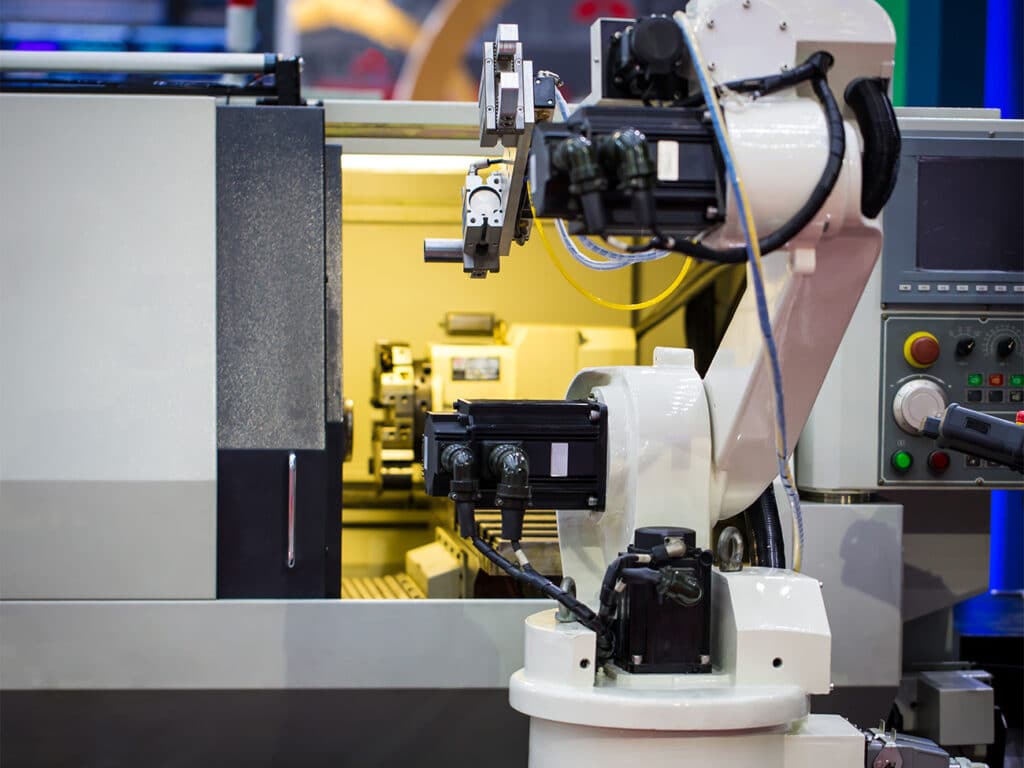

Flexibility also requires the ability to get materials of different sizes and shapes in and out of machine tools. A pair of claws that can serve any product has not yet been invented. But just as multiple tools can be chosen in a machine tool, so too can the robot extract the right tooling for specific products from a warehouse.

Quick payback

Whoever says automation often thinks of high costs. In this area, too, progress has been made in recent years. Robotic technology has become a lot more affordable, but it still comes at a cost, of course. Whereas for most entrepreneurs it is easy to deduce from Excel tables or data from software packages how much the investment in a new CNC machine will yield, this is a much more difficult story for a robot. Especially if none is yet working on the shop floor.

It is important to know that a robot can have a special impact on the entire shop floor. As an entrepreneur, you will be offered new opportunities, for example, to produce at night and on weekends. In other words, your spindle efficiency will go up considerably.

Not only can your machines be better utilized, the same goes for your employees, as the robot takes over the repetitive work from them and they can focus their technical talent on the actual machining work. These are also factors to consider when weighing the return on investment when investing in a robot. To get the full return from the first robot on your shop floor, you would therefore do well to take a step back and look at how and where your production processes can be further optimized by the arrival of a robot.

Mature, proven technology

But what kind of automation solution would best serve your production? This, too, is not easy to quantify when you want to work on a first automation solution. Choosing partners who have already proven themselves in this field is therefore a wise decision. Both machine tool manufacturers and manufacturers of robots and robotic solutions can help you on your way. In recent years, much progress has already been made in creating open interfaces to allow your machine tools and your robot to communicate easily with each other.

The general maxim "keep it simple, stupid" certainly applies here as well. Automation and robotization do not have to become needlessly complex and expensive, even if you want a solution tailored to your production. After all, today there is quite a lot of standard technology to take those first steps in an efficient way. The lower you can make the threshold, the more easily this technology will also be supported by your employees on the production floor, and the faster you will be able to reap the benefits. To realize a shorter ROI, yes, but also to identify new longer-term opportunities. After all, seeing a robot in action on one machine makes it tangible what benefits it can bring to another.

Leveraging talent

But before you take up the phone to place your first order, here's what you need to know. Remember that automation is first and foremost a people's story. As contradictory as that may sound. The technology you invest in actually serves primarily to support your employees. So that they are less burdened while being able to do more. So that they can use their talents to the fullest and get more satisfaction from their work. Thus, the arrival of a robot not only has its impact on productivity, but also on the working atmosphere and innovativeness within your company.