Organized and automated approach to planning brings peace of mind

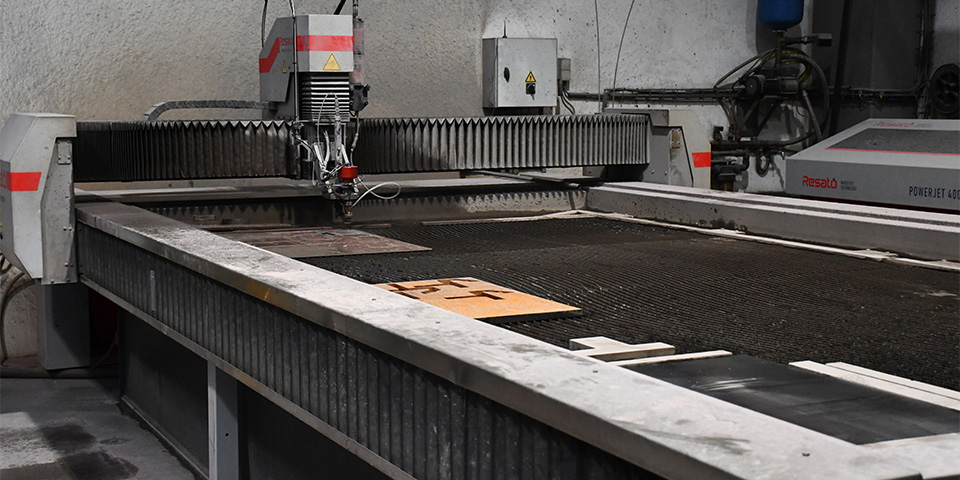

Repairs, machine construction, robotic integration - these are activities which, by definition, often involve piecework. Dewilde Engineering has made it its calling card to completely unburden its customers in these areas. It counts on Trivest Software Group's Ridder iQ ERP package to help it see the forest for the trees. A special custom module also ensures efficient scheduling of the waterjet cutting machine that handles the cutting.

Dewilde Engineering has quite a few years on the clock. It originated in 1937 as Smidse Dewilde which was responsible for repairs to local metal. More than eighty years later, repairs are still an important part of its activities. "Every year we do about 3,000 industrial repairs, from very simple to enormously complex where we build parts ourselves or in consultation with the customer. We are proud of those roots," opens Managing Director Patrick Heughebaert. Dewilde Engineering also focuses on mechanical engineering and the integration of robotics (ABB and Staubli). With its own engineering office, it coordinates the entire realization from the design phase to final delivery. "We do this with the same philosophy: unburdening our customers. To this end, we have a strong team of 35 employees and a high-performance machine park with machining

machines but also sheet metal working."

Value-added ERP package

Per day, our waterjet cutting machine's task list can amount to more than twenty different jobs. We needed a way to set priorities and deadlines.

Dewilde Engineering belonged to the Pidy group for many years. A management buyout followed in 2008. For Heughebaert, it was clear from the start that an ERP package would be crucial in the management of the company. "From the experience within the Pidy group, we knew what added value an ERP package could bring. It may not be the beating heart of the company, but thanks to a high-performance ERP package, you know it's right." In 2009, Dewilde Engineering therefore chose Ridder Data Systems and Ridder8. The switch to Ridder iQ followed in 2017. A choice he still sees as the right one. "Because every repair, every machine is different, we work very project-based. By securing all the information within Ridder, we can continue to see the forest for the trees. Everything can be retrieved quickly and efficiently with highly automated administration."

Module for planning waterjet cutting machine

The advantages of an ERP package also show themselves in the planning of the waterjet cutting machine. Heughebaert: "Because we work with very diverse materials, we rely on a waterjet cutting machine for the cutting work. But precisely because each of our departments can make useful use of it, it is extremely busy. Per day, the task package can amount to more than twenty different jobs. We needed a way to set priorities and deadlines." Trivest Software Group's consultant, Wouter Fonteyn, was therefore put to work developing a customized application for Dewilde Engineering. This was done within the existing Project module. "All tasks are brought together within the parts list 'waterjet list'. The operator of the machine then determines, based on the information in the ERP package that is clear at a glance, what the planning will look like across all departments," says Heughebaert. "But everyone retains visibility of the volume of work and when their pieces will come off the waterjet cutting machine."

Order in chaos

For Patrick Heughebaert, it was clear from the start that an ERP package would be crucial in Dewilde Engineering's operations.

For Dewilde Engineering, this new addition meant a huge increase in efficiency. "The organized and automated approach to planning not only saves a lot of consultation, our planner can also start selecting jobs based on sheet material and thickness. Previously, this was all quite time-consuming. The clear overview now brings everyone peace of mind." Heughebaert is therefore particularly satisfied with the cooperation with Trivest Software Group. "You notice from everything that Ridder iQ is a well thought-out package. The new module for the water jet

cutting actually got there very quickly because the package lends itself to getting the information out that we need. It's actually a matter of using the right filters to get the right visualization. They have brought order out of chaos for us."