Bespoke machining machines for every metal and plastics processing company

From the metal and plastics processing market, there is an increasing need for machines equipped for a specific task. Therefore, Bendertechniek supplies machining machines with a wide selection of different controls and accessories. The company also responds to the increasing demand for unmanned production machines with machines with integrated automation.

Bendertechniek bvba supplies, maintains and overhauls machining equipment for the metal and plastics processing industry. They are located in Hamont-Achel and operate throughout Belgium. From the office, service questions are answered daily and spare parts are organized. They also have a spacious workshop where larger repairs can be carried out in-house. Many parts are available from stock from the parts warehouse. Due to short lines with the various manufacturers, original parts are generally delivered to the end customer within 24 hours.

Belgian market is growing

Bendertechniek has been present in the Belgian market for almost fifty years. In the past, this was done from the Dutch branch. Due to the growth of the Belgian market, a new company was started in 2014 in Hamont-Achel, Bendertechniek bvba. As a result, customers can be reached faster and communication has also become easier. Meanwhile, the company has grown into a full-service company with nearly ten employees who are deployed throughout Belgium for service or commercial purposes.

Bendertechniek has been present in the Belgian market for almost fifty years. In the past, this was done from the Dutch branch. Due to the growth of the Belgian market, a new company was started in 2014 in Hamont-Achel, Bendertechniek bvba. As a result, customers can be reached faster and communication has also become easier. Meanwhile, the company has grown into a full-service company with nearly ten employees who are deployed throughout Belgium for service or commercial purposes.

Customized machines

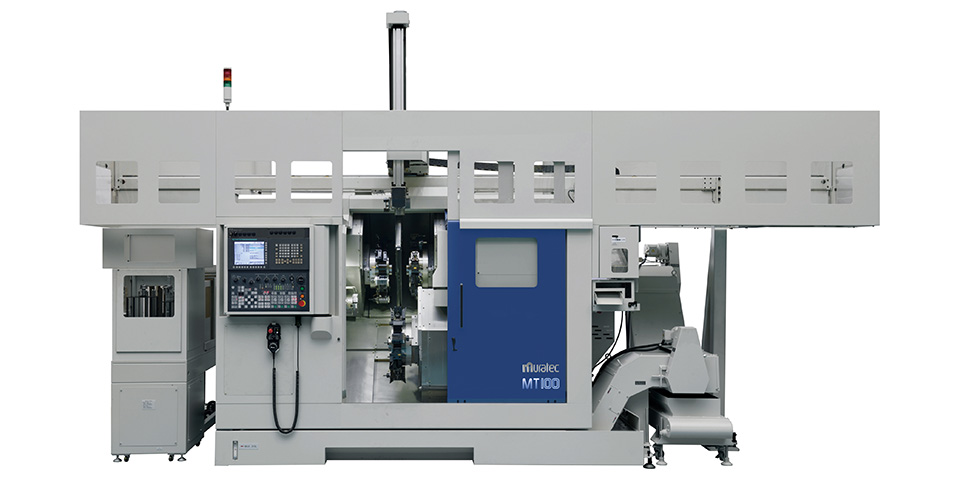

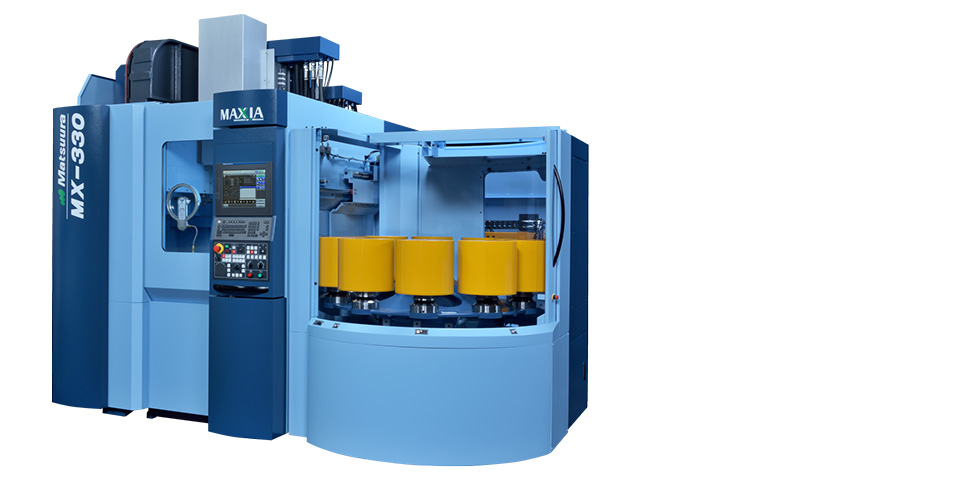

The machine range consists of turning, milling and grinding machines imported from various countries. Among other brands such as Geminis, Hwacheon, Matsuura, Muratec, Rema Control, YCM and Zayer are supplied by Bendertechniek. From the market, there is an increasing need for machines that are equipped for a specific task. Therefore, Bendertechniek not only supplies machines from sixteen manufacturers, but also offers a choice of different controls and/or accessories. This makes it possible to offer every customer a machine that suits their production needs. In order to have as many production steps as possible done by the machine, Bendertechniek also provides things like tool management, breakage detection systems, as well as intelligent crash protections. In addition to a specialized machine, automation is also increasingly important.

Demand for automation increases

To meet the increasing demand for unmanned production machines, Bendertechniek also supplies machines with integrated automation.

In today's economy, unmanned production machines are in high demand. To meet this need, Bendertechniek supplies machines with integrated automation. Example are machining centers equipped with pallet changing systems. But also multitasking machines that can load and unload products. This trend ensures more reliable production with more continuity. This is precisely what makes it interesting for manufacturing companies to invest in automation. In addition to systems provided by machine manufacturers, Bendertechniek has experience in linking machines to external automation systems.

Avoiding unplanned downtime

A production machine, such as a turning and milling machine, should be as reliable as possible. After all, it is the continuity of the machine that makes money. Unplanned downtime is therefore a major setback. Bendertechniek has its own service department that fixes a breakdown as quickly as possible. If it fails over the phone, one of the mechanics will come and repair the machine. The company also advises customers on how to organize preventive maintenance to avoid unplanned downtime in the future. In addition, they also provide annual maintenance to keep the machines in top condition.