Problem-free deep-hole drilling in steel with high hardness and wear resistance

New types of steel require adapted tools. This was experienced at first hand by Viavorm in Geraardsbergen, which specializes in precision metalworking and dies. The family business found the solution at Hoffmann Group.

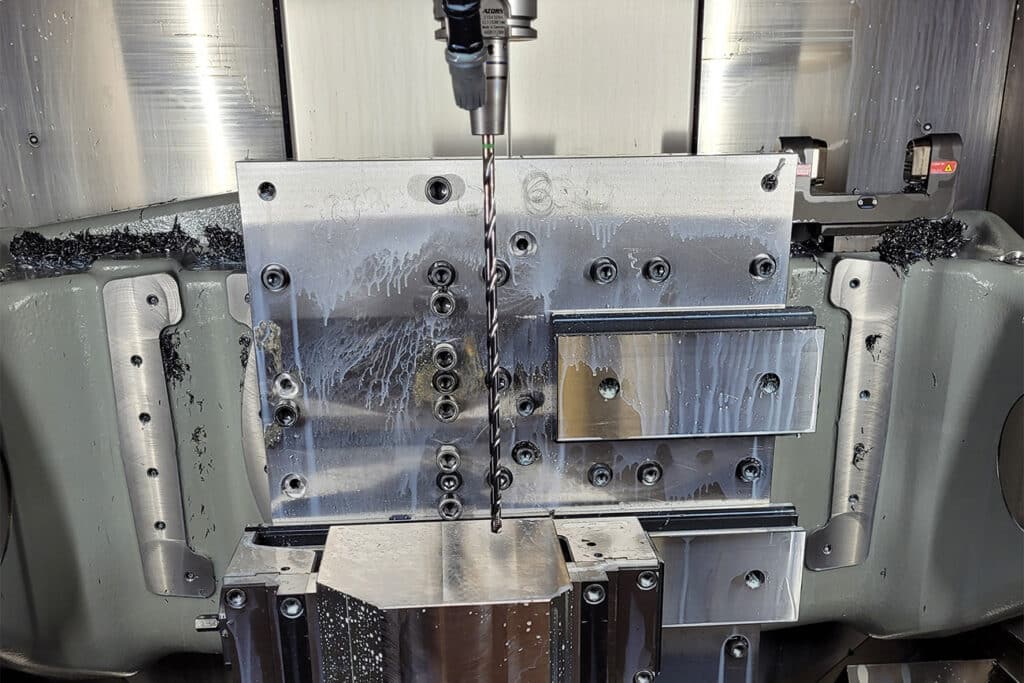

"For a new injection mold that our customer wanted, it was necessary to drill cooling channels in the mold parts. Our customer asked to work with steel grade 1.4112. This material is relatively new at this time. Not all steel suppliers can supply it yet. However, the expectation is that this type of steel will be widely used in die construction in the future because of its special properties," explains Bjorn Lison, co-founder of Viavorm.

High hardness and abrasion resistance

The steel grade 1.4112 contains nearly 20% of chromium, is corrosion resistant and has unusually high hardness and wear resistance. "While drilling the first holes in this material, we observed exceptionally high wear of regular drills. After drilling about four holes, it was already in need of replacement. From there we looked for another solution," says Lison. For this, it turned to Hoffmann Group.

Master Steel DEEP program

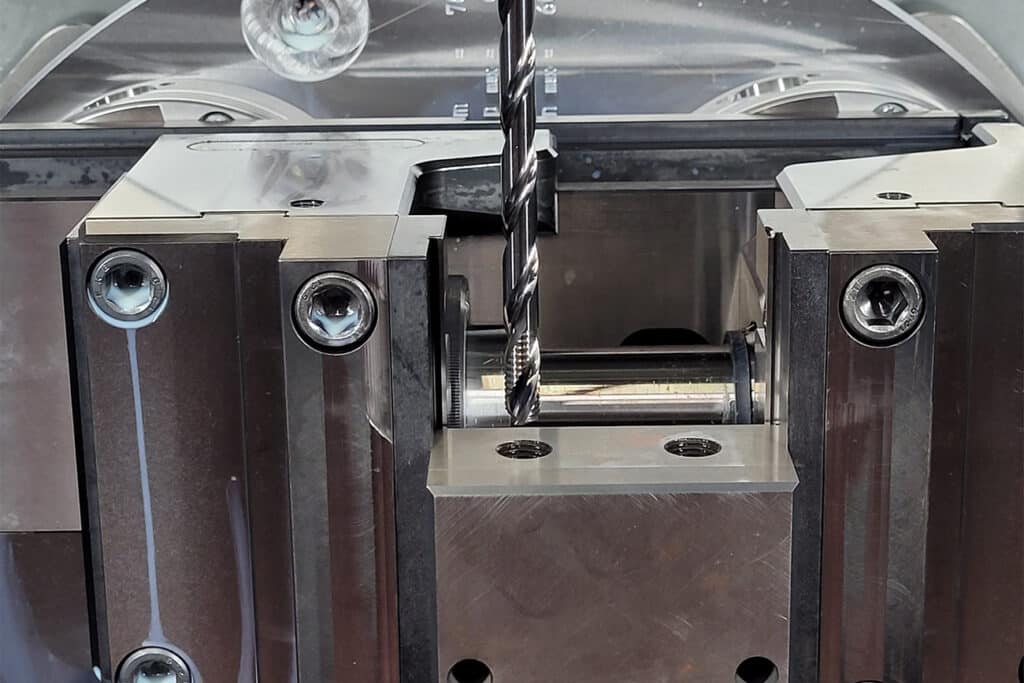

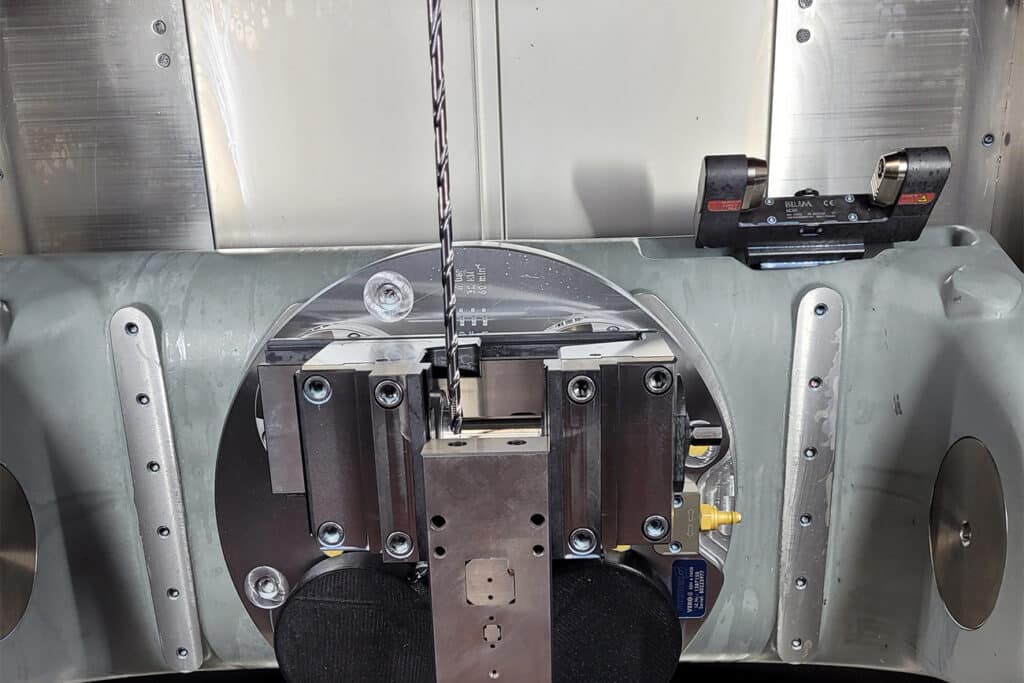

Carlos Cappelle, machining specialist at Hoffmann Group explains. "The material type was also quite new for us. At our headquarters in Germany, we have a database with cutting data for different types of materials, but steel grade 1.4112 was not yet in this database. Nevertheless, we immediately thought that a specific, new drill bit in our range could provide the solution. With our new "Master Steel DEEP" program, we have innovated deep-hole drills that our competitors cannot offer for the time being. Three things are important for a good drilling process in deep-hole drilling: efficient cooling, the guidance of the drill bit and chip removal. The guide rings provide better guidance and better cooling at the top of the drill bit. Partly because of this, cross-drilling is also possible with this drill bit. It does require a certain amount of pressure, but this was not a problem at Viavorm. The dynamic spiral groove, which is also polished, also ensures better and faster chip removal. All this together provides a higher machining volume and a much better tool life."

Positive results

The specific drill and high cut data were presented to Viavorm. Says Lison, "At first I was somewhat skeptical that the results shown could be effectively achieved in practice. Carlos immediately offered support to be present during the drilling of the parts. In consultation with the operator, the drill was placed and we immediately saw positive results after the first drilling." Cappelle adds: "By looking at the chip and wear pattern, a small adjustment was needed for further optimization. So we reduced the cutting speed a bit to reduce friction and the feed was increased. Drilling the rest of the holes - 80 in total, 300 mm deep - was done with these adjusted conditions without problems with one drill bit."

Sustainable cooperation

Lison: "We have been working with the Hoffmann Group for years. Through their online shop it is very easy to order correct products that can be delivered quickly due to a large stock. However, they not only supply products, but also offer technical support and do not look at an hour. That the process goes well is a priority not only for us but also for them. And that leads not only to satisfaction but to a long lasting cooperation."

Database

Finally, Viavorm's cutting data was collected so that the relevant data could be entered into the Hoffmann Group's database in Germany. Cappelle: "In the meantime, we have been able to help many more customers with the Master Steel DEEP program. We get good results with it every time. Our experience with customers like Viavorm means that we can honestly say that we have a product in our hands that leaves the competition far behind."