Proprietary products best remedy for rapid changes in production

A reputation as a technological pioneer in first clamping and then gripping is not built up overnight. It is the result of always sensing what customers need. That is how SCHUNK pushes the boundaries every year. The secret behind this success lies in the in-house production process. There, SCHUNK products have to prove their added value to produce small series as economically as possible.

"By using our own products, we know perfectly how they can add value and where there are still possible improvements for the future."

An old lathe marks the starting point in the history of SCHUNK. In 1945, Friedrich Schunk founded a mechanical workshop in his garage in Lauffen am Neckar to make parts and repairs for local farmers. He quickly gained a reputation as an intelligent craftsman and was trusted to produce brake drums and flywheels for the NSU Prince 4 and precision parts for the Porsche 256. This initial order ran for a period of four years. For son Heinz-Dieter SCHUNK, meanwhile working in his father's business, it gives time to brood on a new product: chuck chucks for chucks.

The common thread throughout the rest of SCHUNK's history remains that drive for innovation, even with Hendrik A. and Kristina I. Schunk, who took over the helm from their father in the meantime. (Image: Sven Cichowicz)

After all, father and son's motto is that only innovation can move a company forward. This is the beginning of a new era that in 2018 leads to a catalog of up to 300 pages of solutions in clamps. In 1982, it adds the second branch to its portfolio: gripping technology. From then on, the industry can call on an extra pair of hands with great finesse. The common thread throughout the rest of SCHUNK's history remains that drive for innovation, even with Hendrik A. and Kristina I. Schunk who took over the helm from their father in the meantime. It has propelled the company to the place of world leader in clamping and gripping technology with more than 3,500 employees and sales of 415 million euros. SCHUNK products are present today in all parts of the machine.

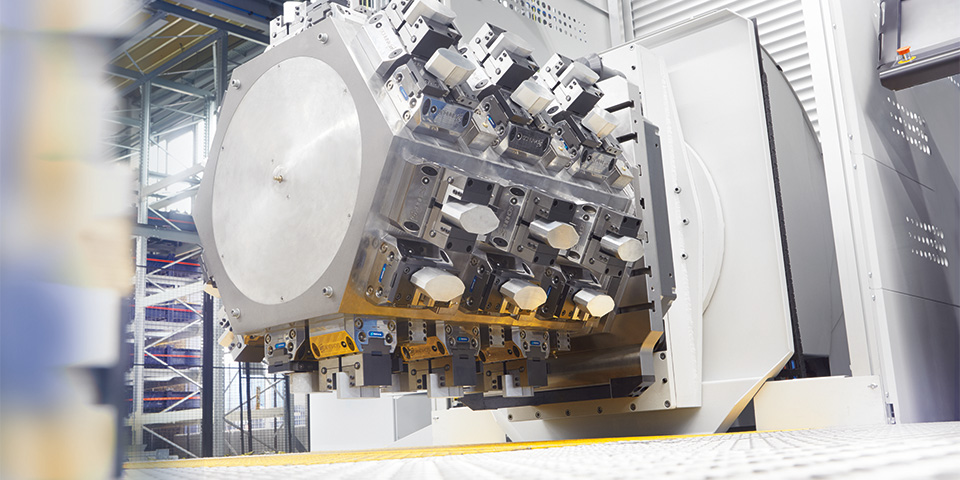

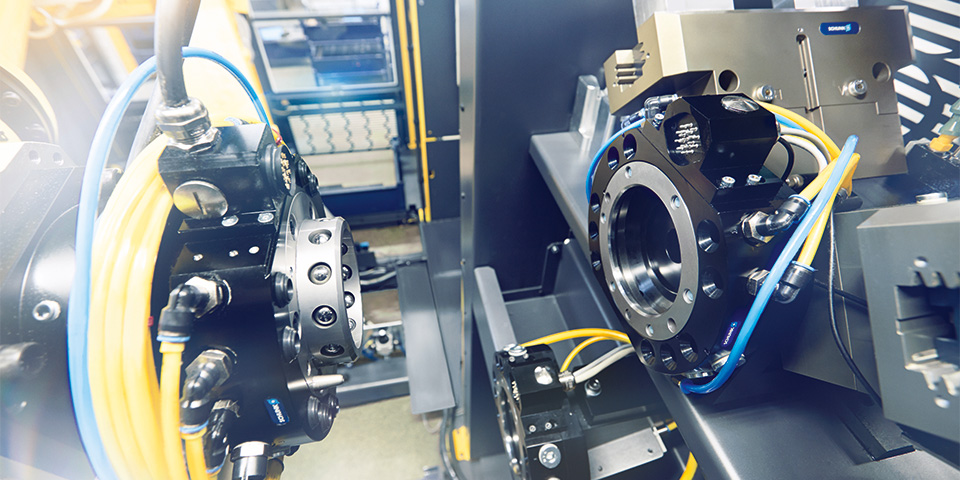

Automation sets the tone in the production halls of SCHUNK.

Evolutions customers also experience themselves

Its headquarters are still located in Lauffen am Neckar. The production site belonging to it has shaped the company's original specialization, clamping technology, since 1966. First with claws, three years later the first tool holders also followed. Like its customers in the metal industry, SCHUNK deals with high mix, low volume production. Reducing downtime and set-up times, maximizing flexibility, increasing the ease of use for operators ... are goals that sound equally familiar to every metalworker. To meet them here in the production hall in Lauffen am Neckar, SCHUNK relies primarily on its own products to make quick changes.

SCHUNK can call itself the world leader in clamping and gripping technology with more than 3,500 employees and sales of 415 million euros.

Denis Lebeau, Managing Director of SCHUNK Intec Belgium: "SCHUNK is still a metalworker at heart. The evolutions our customers are exposed to, we also experience ourselves. Small batches and many changes between products and series are daily business here. Not only because of the wide standard range that customers can choose from, we also do specials, entirely according to their wishes. Single pieces, in other words. By using our own products, we know perfectly how they can be of added value and where there are still possible improvements for the future in terms of performance, tool life, speed, etc."

Thanks to its own products, SCHUNK can quickly switch between products and series in its production.

Thanks to the smart changing systems SCHUNK is developing, among other things, claws can be changed in seconds today.