New software update offers unique added value for long-turners and multitasking machines

Standing still is going backwards. For years, GibbsCAM software has been a very familiar sight for those who want to get the best possible performance from their CNC machines. Users can quickly get started with the flexible programming capabilities to efficiently generate optimized CNC programs. Version thirteen will soon go one step further and add unique options for long-turning and multitasking machines in addition to an updated interface. 4D CAM is responsible for the distribution in the Benelux countries

For years, GibbsCAM's software has been a very familiar sight for those who want to get the best possible efficiency from their CNC machines.

GibbsCAM will soon launch version thirteen of its CAM software, fully translated into Dutch. With additional features and interface improvements, it brings a solution of added value to both seasoned users and newcomers. Liesbeth Raes, application engineer GibbsCAM for 4D CAM clarifies why developer 3D Systems took a new tack: "In addition to providing a modern look and feel, the software must above all optimize the user experience. A gain in efficiency and productivity is what comes first with the new interface, without the transition between the two versions involving much complexity. From now on, the user will have even more opportunities to arrange the interface and menus to their liking and build their own palettes and libraries." The result is productivity up to 30% higher. In addition, GibbsCAM also offers notable advantages for those who want to program multitasking machines or long-turners efficiently.

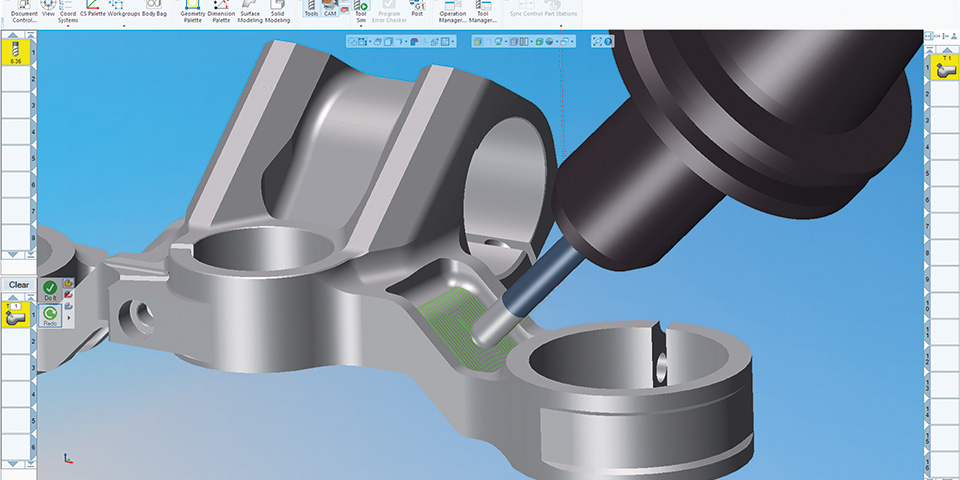

Expansion of cutting strategies

With GibbsCAM MTM, the software developer already gave an answer to the specific programming requirements that multitasking machines entail in terms of set-up, spindles, tools ... With its intuitive interface, users have seamless access to both turning and milling capabilities where flexibility and configurability are key. To get maximum productivity from all CNC machines, multitasking machines included, GibbsCAM expanded its cutting strategies even further in version thirteen. Three notable novelties in this are interpolar, eccentric and elliptical turning. "I have not yet come across other CAM systems that offer solutions for this," Raes says proudly. "With interpolation, the spindle rotates so that the turning tool stays in line with the workpiece. This allows turning on milling, drilling and turning machines with orientable spindles. Eccentric turning, in turn, allows turning operations to be performed for shapes that are not aligned with the central axis of a piece, such as for a crankshaft. Finally, with elliptical turning, you can start creating elliptical and other non-cylindrical shapes with a CNC machine."

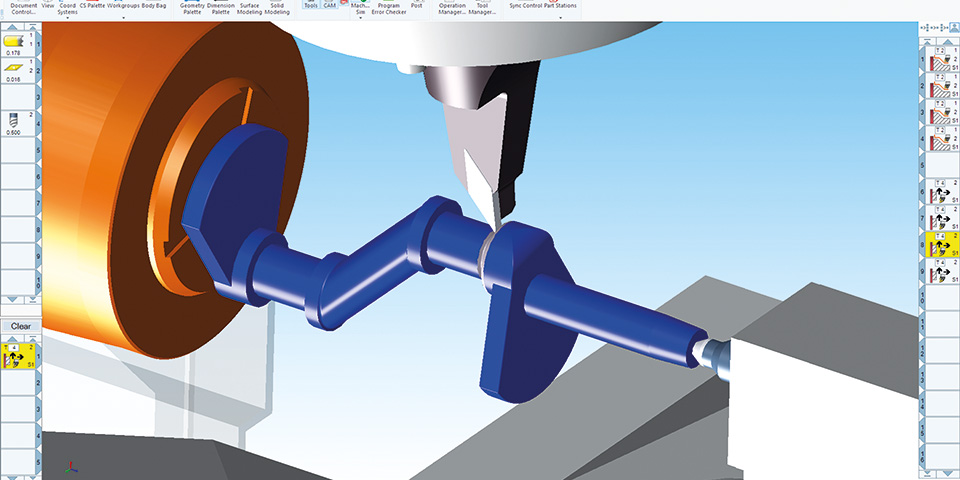

Extra attention to long-turning

Interesting new capabilities were also added for long-turning. "Long-turners are designed to manufacture small, complex precision parts. Unlike conventional CNC lathes, the tool will be stationary and the part will make a movement along the Z axis. The piece goes in and out of the guide sleeve, but after rough machining, burrs may remain on the outside of the material. This can cause damage to the guide bushing. GibbsCAM 13 solves this by introducing the bar chamfering feature. This automatically determines chamfering when the material is on to avoid burrs. The length will only be able to be as long as the depth pass. There are also a lot of options for controlling chip chamfering. You can set how far the tool retracts (Pull-Off), how many wraps the tool stays in place before cutting further (Dwell) and how long the chip must be before "Pull Off" or "Dwell" is activated. This is enormously useful in the turning processes of contouring and roughing," concludes Raes.