The impact of Cellro automation on the work process (Hardware)

In a previous article went software engineer Dirk elaborated on the various possibilities and in particular the simplicity with which you can set up the controls of our automation yourself. In this article, mechanical engineer and product manager Bram Koning follows that up from his expertise. He zooms in on the hardware of our automation for product handling.

Impact at the product level

By work process, we mean primarily the loading and unloading of machines, such as CNC lathes, milling machines, wire EDMs, etc. These are all expensive machines that need to run as much production as possible. The automation solutions of Cellro are therefore aimed at achieving as many "spindle hours" as possible with your machinery. It is our challenge to put together the most suitable automation application for you. Can you, for example, cope well with Xcelarate, or close Elevate, Modulerate or Ultimate better match the work process in your company? One thing these four products have in common. The hardware offers numerous flexible options in terms of fixtures, grippers and storage. When making the right choices from the various options, your production process and your products are always the focus.

Impact in terms of robotic cell configuration

The better the automation matches your machinery and the work process within your company, the greater and more positive the impact will be. We advise you in putting together the most suitable robot cell configuration, taking CNC machine functionality into account. As well as the product mix and desired storage capacity. The modular construction of robot cells makes Cellro automation solutions distinctive. Simplicity is our starting point and optimal efficiency for your business is our goal.

Impact of good hardware

Which automation for product handling is most suitable in your company depends on several factors. What machines do you use, what kind of products do you make and in what numbers (series) do you produce certain products? These questions determine the fixturing, the type of gripper or grippers to be applied and layout and storage space for the products. Can the product be clamped with the same jaws that can be used to clamp the rough part, or do you have multiple zero-point clamping systems in your machine that have clamps for each machining step? Can the same gripper be used for the rough part and the semi-machined part? Or are multiple grippers needed with different fingers? Is the geometry of the product suitable for automatic turning on the takeover station? The more concrete our hardware is tailored to this, the greater the efficiency gains you can make with Cellro's smart automation.

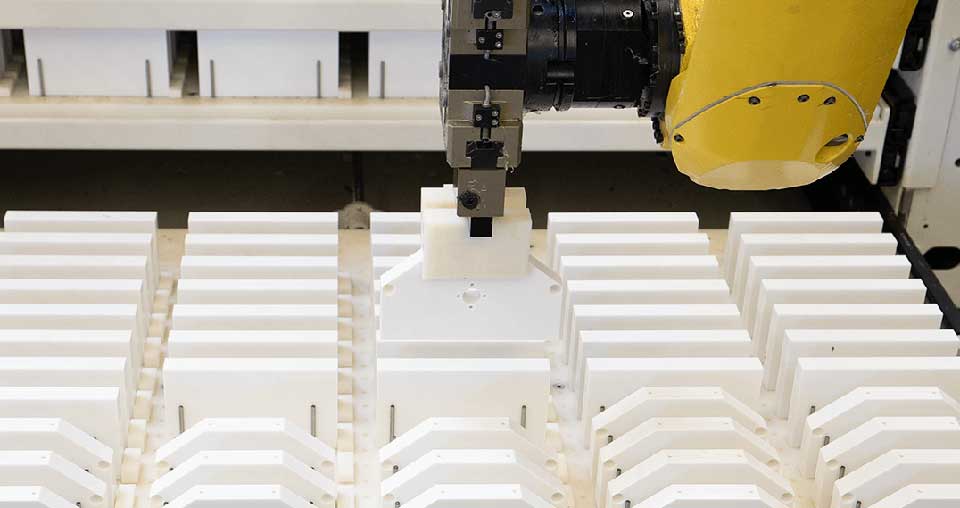

Impact through smart product storage

Cellro uses a horizontal product carrier in all robotic cells. This can be a drawer or a tray. By storing products on top of each other, a high storage capacity can be achieved on a compact floor space. After all, width costs money, height does not. The inlays ensure that products are stored orderly in the trays by the robot. You can use our standard inlays, but you can also create your own inlays to match products with unique shapes. As long as these have a repeating character to work from. It is important to determine which inlays and with how many drawers or trays you will be able to keep your production running unmanned for as long as possible

Impact on returns

An important question from business owners is what the impact of automation is in financial terms. What does it cost and what does it give you? We have a calculation module available for this purpose. This enables us to show the extent to which spindle hours increase and labor costs decrease. For companies that run 24/7, the impact will naturally be greatest. But also customers who usually work with constantly changing products in smaller series indicate that Cellro's automation solutions provide a significant increase (sometimes as much as a doubling) of the number of spindle hours. As mentioned earlier, finding the optimal robot cell configuration for product handling automation within your company is the biggest challenge here. It is a combination of the right machine, the best fixture, the most suitable gripper(s) and sufficient carefully allocated storage space for your products.

View the video in which product manager Bram de Koning elaborates on all the flexible possibilities with which the hardware of our automation can be fully tailored to your work process. Or take contact with us to discuss options and calculate the costs and benefits for you.