Flexibility, quality and delivery reliability in machining, sheet metal and welding work

Now it wants to complete the circle by applying this proven approach to machining. Shapes Machining was born from the acquisitions of Protech and Giropan, brought together in one base of operations in Kuurne. "This way, we have the know-how and machinery to offer our clients a wide range in machining. Shapes is thus a true one-stop shop for all metal machining."

From its locations in Gullegem and Roeselare (soon to be Kuurne), Shapes Metalworks focuses on sheet metal fabrication and welded structures, respectively. "It emerged in 2014 from the merger of FP Metal and Shapes Subcontracting. By resolutely working together, we managed to more than double our turnover over a five-year period," general manager Dirk Haerinck proudly tells us. A success story supported by three elements that make up Shapes' DNA: quality, flexibility and delivery reliability. "Our focus is on prototypes and small to medium series that we finish perfectly according to the customer's wishes. As a supplier, quality should be the basis of everything you deliver. Deploying a very diversified machine park gave us the reins to respond quickly to customer requests with competitive delivery times. Promises we keep every day in practice."

Third business leg: machining

Thanks to this proven approach, a lot of customers also come to Shapes for parts that require machining in addition to sheet metal. Haerinck: "You can sense a trend that companies are increasingly looking for a permanent partner, a one-stop-shop where they can place their product for the entire process." For years, Shapes Metalworks has counted on supplier Protech (Torhout) for that. "Because we share that same eye for flexibility, quality and delivery reliability. When the business manager indicated he had no successor in his own ranks, we were at a crossroads." A fork in the road that ultimately turned out to be a huge opportunity. Shapes decided to create a third business arm. One dedicated entirely to machining: Shapes Machining. The addition of 'large machining company' Giropan completes the picture. After all, in Kuurne the young company is given every opportunity to develop further. But with the same key values: quality, flexibility and delivery reliability.

Wide range of operations, sizes and materials

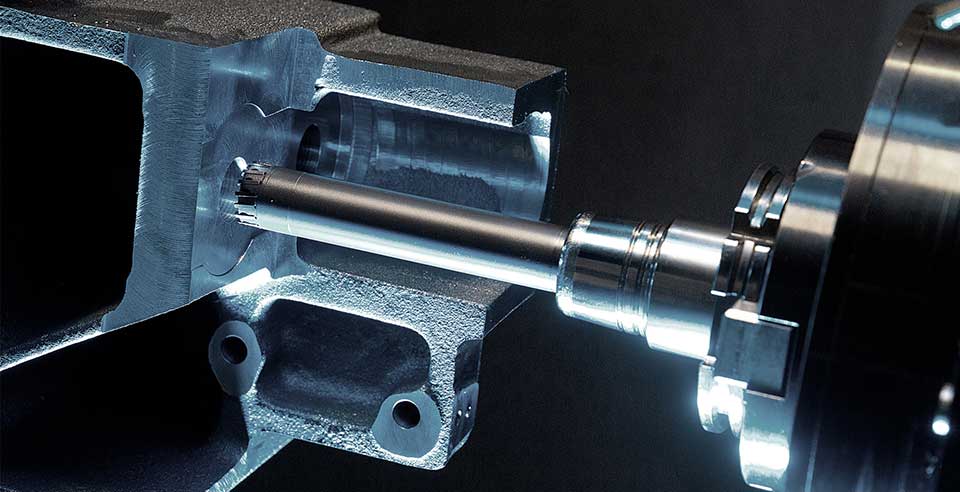

To manage the machining work, Benjamin Degandt joined the ranks as business unit manager. He brings with him more than five years of experience in machining and quality control. "Protech and Giropan each sailed in their own waters with very different customers and machines. By bringing everything together at one location in Kuurne, we immediately have a very diverse range of machinery available for turning and milling small to very large, bulky pieces in steel, cast iron, stainless steel, plastic, copper, brass .... This allows Shapes Machining to handle a wide range of machining operations right from the start. We complement that with the technicality and experience of the twenty or so employees who were already there. All of them specialists at their machines." That everyone stayed on board after the merger has a lot to do with the approach. "In machining, too, we focus on piecework and small to medium series. That makes everyone from the draftsman, programmer to the operator have a varied job," says Degandt.

Investing appropriately

In addition, Shapes Machining has made the necessary improvements to the infrastructure with a view to employee comfort and future expansion. After all, the company started out with the necessary ambition and aims to double its turnover. Degandt: "We will also make appropriate investments to realize this ambition. The base of operations in Kuurne still leaves us room to double the surface area of the shop floor. But we initially want to look at how we can achieve a state-of-the-art machine park and automate and digitize where possible to remain competitive. The ISO-9001 certificate remains the backbone for quality." Meanwhile, the move of Shapes Metalworks' welding construction work from Roeselare to Kuurne is also in full swing. "After all, our sawing department is the starting point for both. By bringing them under one roof, we are making efficiency gains and it allows us to create some space in Gullegem for the further growth of the sheet metal working machinery," Haerinck adds.

Lever

By the end of April, the integration should be complete in Kuurne. "From then on, we want to take full advantage of the synergies that exist. Few companies today make the combination of sheet metal, welding and machining, precisely because they are three different worlds. With Shapes Machining and Shapes Metalworks, we have the know-how and experience in all three areas. We can now completely establish ourselves as a one-stop shop for our customers. We believe it will be a lever to an even brighter future under the motto 'We Shape Your Ideas,'" Haerinck said.