In case of emergency stops, however, they are capable of much more. Damping specialist ACE Stoßdämpfer GmbH thereby has almost 60 years of experience in the development of new technologies and knowledge of all sizes. In this way, engineers always find the appropriate damper for their installation.

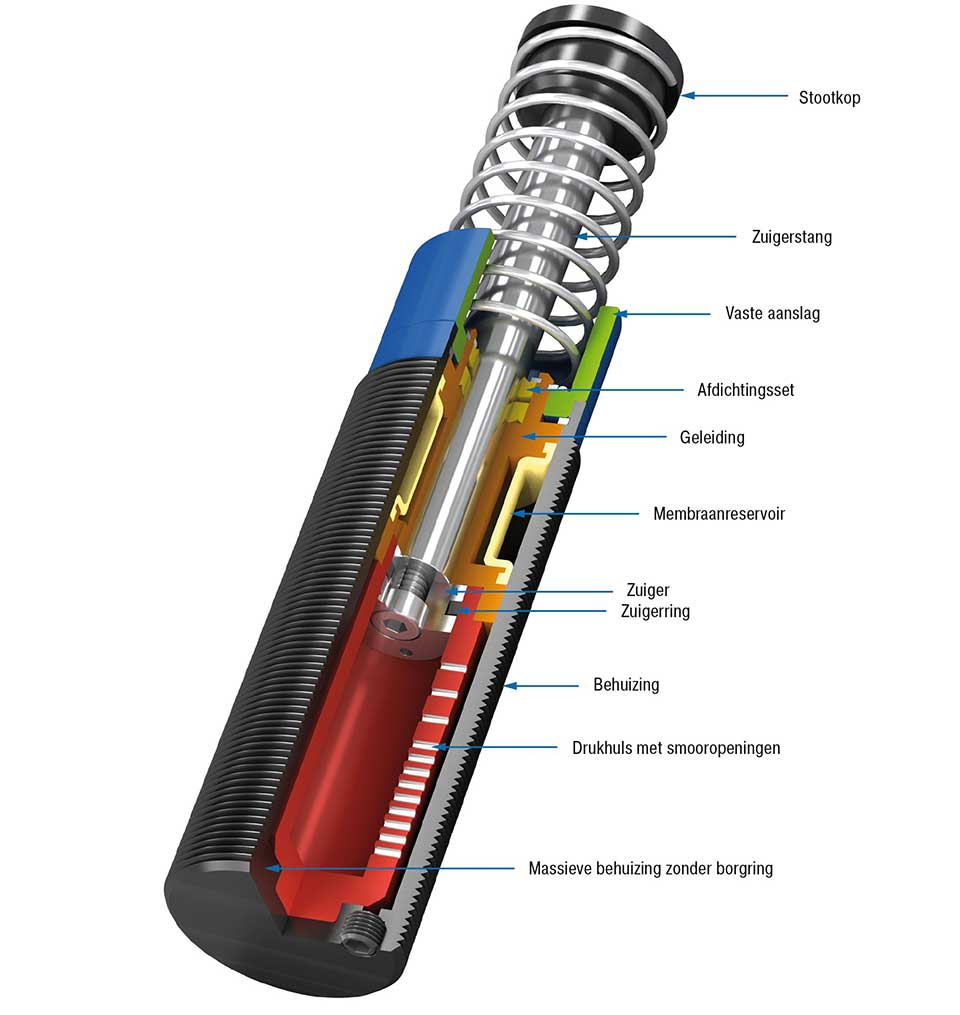

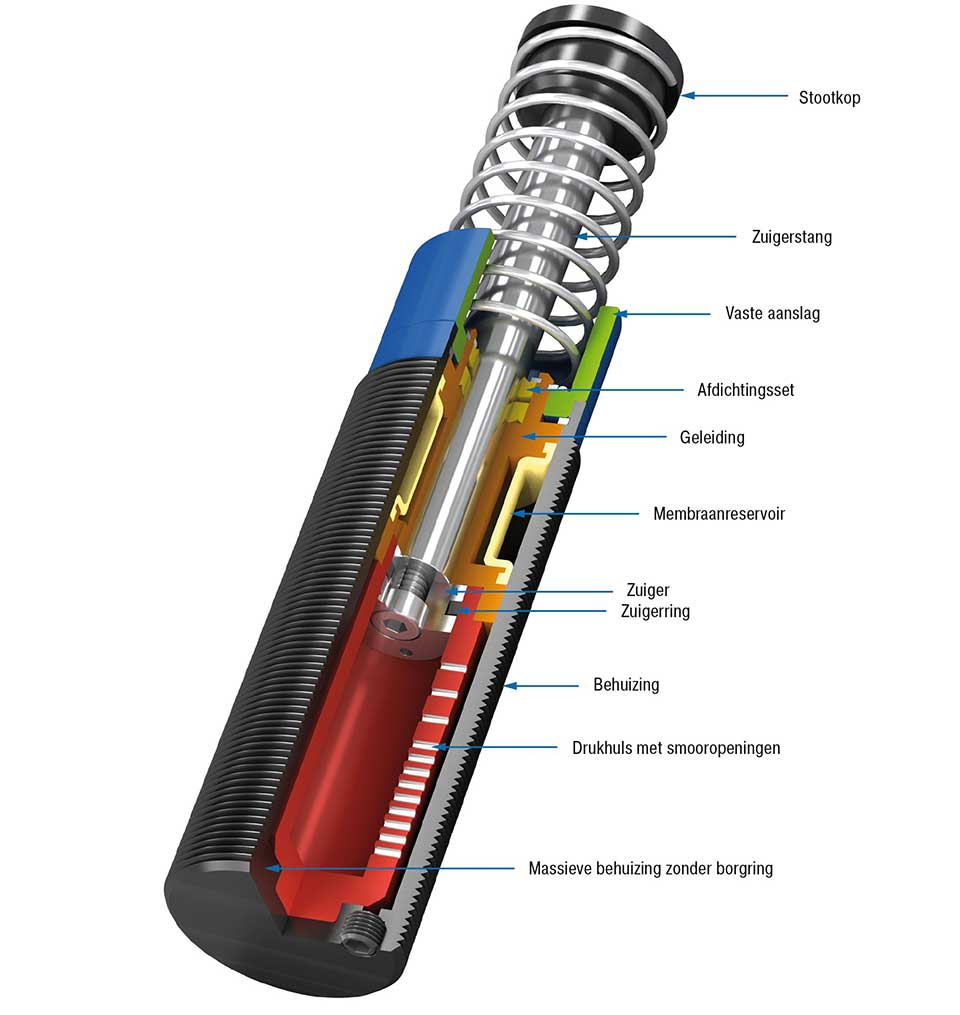

In particular, the precise and recoil-free braking of effective masses up to 326,000 kg is a real mammoth task. Designers of transport and gantry equipment, or reach trucks often rely on heavy-duty industrial shock absorbers from ACE to protect their machines. As with the Langenfeld-based company's small- and medium-sized models, this type of overrun protection device presses the piston rod into the cylindrical damper element during deceleration and simultaneously forces hydraulic oil for the piston through all choke openings.

Since the number of effective choke openings decreases as the rod is sucked further in, not only does the retracting speed remain constant, but the thrust pressure and counterforce for the piston also remain the same. In addition to the effectively brakeable high mass, this is a decisive advantage over other available damper solutions. While the braking process with small impact dampers from ACE takes only a fraction of a second, the hydraulic heavyweights require up to 2.3 seconds to overcome a stroke length of more than 400 mm. In this way, it is possible to brake even large masses completely and without recoil effect accurately and gently.

Large range for a variety of applications

Heavy-duty industrial impact dampers in self-adjusting or adjustable versions are characterized by their robustness and rapid deployment. ACE's series of heavy-duty self-adjusting dampers are also suitable for emergency stopping applications, as are the adjustable dampers. The effective mass to be braked can even be increased significantly. The dampers are custom designed for each application using ACE's calculation tool.

This eliminates the risk of crashes and incorrect settings. The CA types are suitable for braking both very small and very large masses. They are already usable for braking effective masses from 700 kg and 3,600 Nm/stroke. The largest dampers with a stroke length of up to 406 meters and an energy absorption of 126,500 Nm per stroke can even slow down effective masses of up to 115,000 kg. Durable dampers are used particularly in heavy engineering.

Test bench equipped with safety shock absorbers

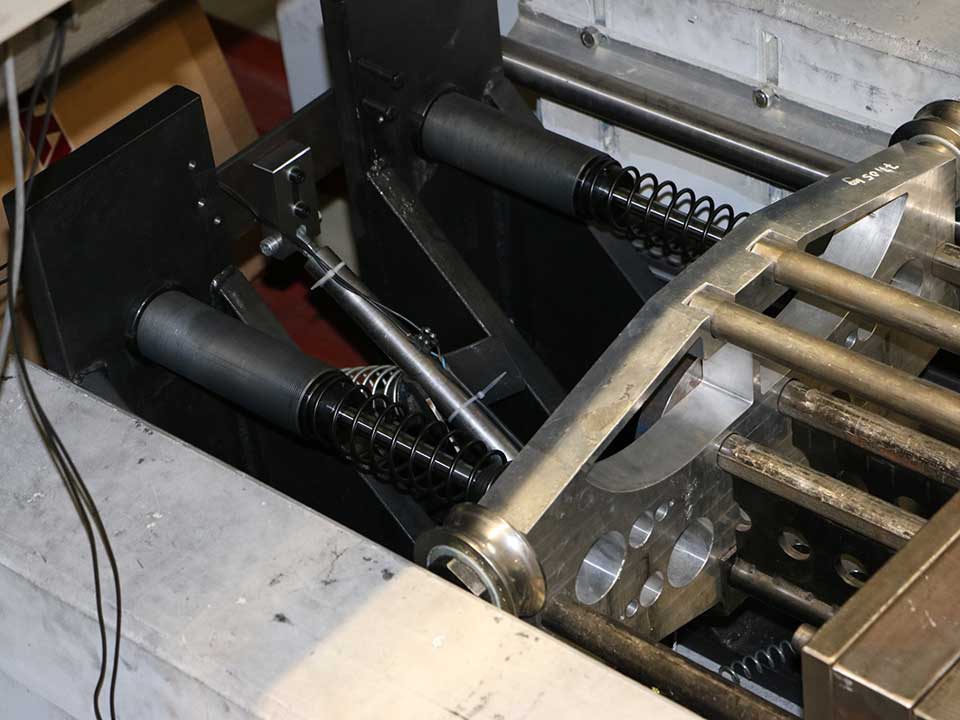

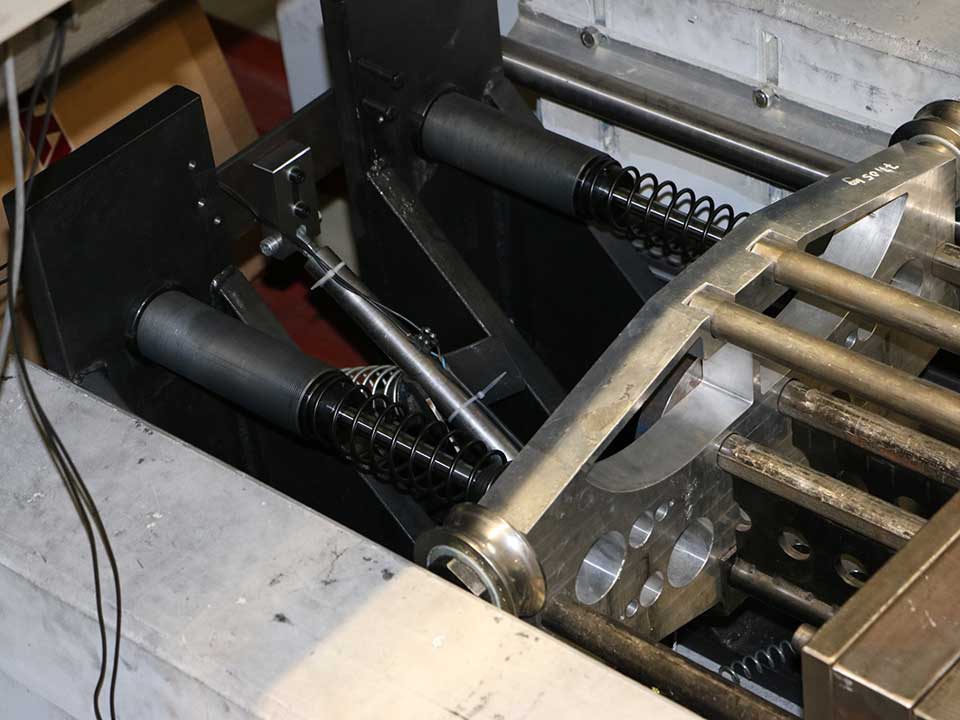

The work of heavy industrial shock absorbers can be illustrated by their function in a test bench. In this case, they are installed at the end of a 6-meter-long acceleration track. Over this slides a carriage with test material. The dampers are designed to slow the kinetic energy to 32 kj. This is to ensure that after testing a particular material, the test bench can be used undamaged for crash tests and subsequent measurements at modified speeds.

And that as safely, flexibly and maintenance-free as possible. In an earlier test stage, safety dampers from ACE of the TUBUS TA, TC and TC-S series were used for this purpose. Since these components made of co-polyester elastomer could not fully absorb the mass without recoil from the carriage, the company's hydraulic safety dampers were chosen in the next step. These impact dampers can absorb the forces of the moving mass evenly over the entire stroke length and brake it in the end position with extreme precision. The load on the impact absorbers is very high in the process. Immediately after the impact, the internal pressure in the pressure sleeve rises abruptly to 460 bar. As a result, the damper oil starts flowing much faster within a short time, at a speed of up to 750 km/h. In order to finally develop the optimal safety damper, during the course of cooperation and installation, all required parameters from the test bench at ACE were entered into the aforementioned proprietary calculation tool. The ideal damping characteristics for a wide range of masses and impact speeds were then determined. Engineers at ACE then incorporated these precisely into the SDH and SCS type safety dampers used in the crash installation.

Inexpensive alternative to industrial shock absorbers

Not only in this case, safety shock absorbers are an economical alternative to ACE's even more powerful industrial shock absorbers. While certain types of safety shock absorbers are designed for continuous use, they primarily serve as reliable, effective protection of structures in emergency stop situations. With the types from the product series SCS33 to SCS64, which are also used in the test bench described here, ACE uses standard components of MAGNUM shock absorbers. Thanks to their even more robust design, cycle life of up to 1,000 strokes can be achieved with these. Safety dampers from ACE are available in a wide range of designs with different stroke lengths and energy absorption. The location of the choke holes can be calculated and implemented customer-specifically. Safety shock absorbers from ACE, especially the SCS product series, are proving to be the answer to increasingly complex requirements in drive engineering. With their compact dimensions and immense energy absorption in crashes, they protect ever smaller and faster structures. These damping elements provide instant deceleration, up to 300 percent higher energy absorption and over 80 percent lower cost per Nm of energy absorption compared to other industrial shock absorbers from ACE. Therefore, they are often an interesting alternative, especially when it comes to ensuring safety.

Industrial shock absorbers from ACE: damping in all dimensions

In case of emergency stops, however, they are capable of much more. Damping specialist ACE Stoßdämpfer GmbH thereby has almost 60 years of experience in the development of new technologies and knowledge of all sizes. In this way, engineers always find the appropriate damper for their installation.

In particular, the precise and recoil-free braking of effective masses up to 326,000 kg is a real mammoth task. Designers of transport and gantry equipment, or reach trucks often rely on heavy-duty industrial shock absorbers from ACE to protect their machines. As with the Langenfeld-based company's small- and medium-sized models, this type of overrun protection device pushes the piston rod into the cylindrical damper element during deceleration and simultaneously forces hydraulic oil for the piston through all choke openings.

Since the number of effective choke openings decreases as the rod is sucked further in, not only does the retracting speed remain constant, but the thrust pressure and counterforce for the piston also remain the same. In addition to the effectively brakeable high mass, this is a decisive advantage over other available damper solutions. While the braking process with small impact dampers from ACE takes only a fraction of a second, the hydraulic heavyweights require up to 2.3 seconds to overcome a stroke length of more than 400 mm. In this way, it is possible to brake even large masses completely and without recoil effect accurately and gently.

Large range for a variety of applications

Heavy-duty industrial impact dampers in self-adjusting or adjustable versions are characterized by their robustness and rapid deployment. ACE's series of heavy-duty self-adjusting dampers are also suitable for emergency stopping applications, as are the adjustable dampers. The effective mass to be braked can even be increased significantly. The dampers are custom designed for each application using ACE's calculation tool.

This eliminates the risk of crashes and incorrect settings. The CA types are suitable for braking both very small and very large masses. They are already usable for braking effective masses from 700 kg and 3,600 Nm/stroke. The largest dampers with a stroke length of up to 406 meters and an energy absorption of 126,500 Nm per stroke can even slow down effective masses of up to 115,000 kg. Durable dampers are used particularly in heavy engineering.

Test bench equipped with safety shock absorbers

The work of heavy industrial shock absorbers can be illustrated by their function in a test bench. In this case, they are installed at the end of a 6-meter-long acceleration track. Over this slides a carriage with test material. The dampers are designed to slow the kinetic energy to 32 kj. This is to ensure that after testing a particular material, the test bench can be used undamaged for crash tests and subsequent measurements at modified speeds.

And that as safely, flexibly and maintenance-free as possible. In an earlier test stage, safety dampers from ACE of the TUBUS TA, TC and TC-S series were used for this purpose. Since these components made of co-polyester elastomer could not fully absorb the mass without recoil from the carriage, the company's hydraulic safety dampers were chosen in the next step. These impact dampers can absorb the forces of the moving mass evenly over the entire stroke length and brake it in the end position with extreme precision. The load on the impact absorbers is very high in the process. Immediately after the impact, the internal pressure in the pressure sleeve rises abruptly to 460 bar. As a result, the damper oil starts flowing much faster within a short time, at a speed of up to 750 km/h. In order to finally develop the optimal safety damper, during the course of cooperation and installation, all required parameters from the test bench at ACE were entered into the aforementioned proprietary calculation tool. The ideal damping characteristics for a wide range of masses and impact speeds were then determined. Engineers at ACE then incorporated these precisely into the SDH and SCS type safety dampers used in the crash installation.

Inexpensive alternative to industrial shock absorbers

Not only in this case, safety shock absorbers are an economical alternative to ACE's even more powerful industrial shock absorbers. While certain types of safety shock absorbers are designed for continuous use, they primarily serve as reliable, effective protection of structures in emergency stop situations. With the types from the product series SCS33 to SCS64, which are also used in the test bench described here, ACE uses standard components of MAGNUM shock absorbers. Thanks to their even more robust design, cycle life of up to 1,000 strokes can be achieved with these. Safety dampers from ACE are available in a wide range of designs with different stroke lengths and energy absorption. The location of the choke holes can be calculated and implemented customer-specifically. Safety shock absorbers from ACE, especially the SCS product series, are proving to be the answer to increasingly complex requirements in drive engineering. With their compact dimensions and immense energy absorption in crashes, they protect ever smaller and faster structures. These damping elements provide instant deceleration, up to 300 percent higher energy absorption and over 80 percent lower cost per Nm of energy absorption compared to other industrial shock absorbers from ACE. Therefore, they are often an interesting alternative, especially when it comes to ensuring safety.