If it really has to be straight

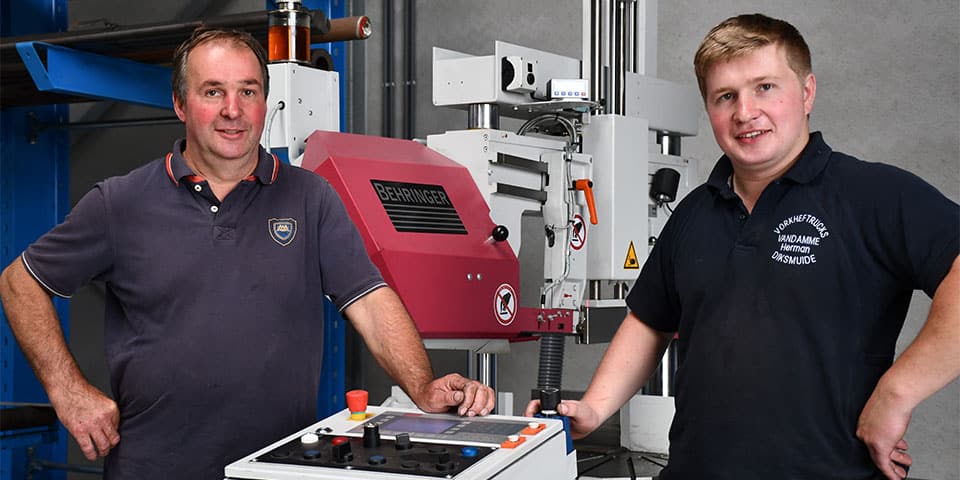

Anyone who wants to adapt their forklift to their products will need mechanical modifications. A case in point for Mechanization Vandamme of Diksmuide, which manufactures the necessary pieces itself based on the customer's wishes. Expertise that it also puts at the disposal of companies looking for piecework in turning and milling. To start with proper sizing, the company recently invested in a Behringer sawing machine. "The first machine that cuts really straight and does not vibrate. Worth every euro," summarizes case manager Herman Vandamme.

He did not have to look far for the entrepreneurial blood. His parents operated a butcher shop in Diksmuide, but Herman Vandamme inherited his passion for technology from his grandfather. "As a young guy, I loved nothing more than tinkering with tractors on his farm," he says. It inspired him to help out local farmers with mechanization work. Today, the focus is more on industry and forklifts. "Half the work that passes through here has to do with modifications to forklifts. Flexibles, cylinders, small mechanical engineering, common rail diesel systems ... we do it all. But the machinery is also available for subcontracting in turning and milling."

Finding solutions together

What typifies Vandamme Mechanisatie is the special relationship with customers, many of whom find their way to Diksmuide from a radius of 50 km. Vandamme: "For 27 years I have only done the work here in the workshop. That direct contact to look for solutions together creates a strong bond. You don't only want to earn money but also feel good about what you deliver." Five years ago, son Benoit also joined the ranks. The signal to "put another patch" on it. Plans for a new building adding 1,200 m² of studio space are now out of the starting blocks. In it should come a lathe that can also handle the larger work. "A niche with somewhat less competition in and where we, as a small family business that can move quickly, have a strong asset. Forward-looking, but with the arrival of a new sawing machine in 2020, the first hurdle has already been taken. Because everything starts with a perfect cut."

With a range of up to 520 mm in diameter, the new Behringer saw machine is one size larger than its predecessor. Moreover, it cuts both profiles and full material perfectly to size.

Never another

Vandamme resolutely chose the Behringer brand, represented by Promatt. "A local customer had whispered to me that once you worked with a Behringer saw machine, you wouldn't want anything else. And he was right. This is the first machine here on the shop floor that really cuts straight and eliminates vibration. These are clearly machines that are very well thought out and, above all, well made." With a range of up to 520 mm in diameter, the new Behringer saw machine is a size larger than its predecessor. Moreover, it cuts both profiles and full material perfectly to size. "For this, you can switch very quickly between sawing with coolant and the dry lubrication system. An additional advantage is the large passage, which means we now no longer have problems with chip removal." A new roller conveyor system will soon follow. This will allow material to be loaded with a forklift.

Order and cleanliness

Vandamme is also particularly pleased with Promatt's service. "The machine was installed during the coronalockdown, as agreed. Of course provided that all safety regulations were observed. The team ensured clean and proper assembly. Anyone who walks into our production hall will immediately see that order and tidiness are important priorities for us. After all, that carries over into your work. We were happy to find the same mentality among the mechanics of Promatt and Behringer," concludes Vandamme.