Innovative machinery and customized service are the keys to success

Manufacturing companies, planning the purchase of a new machine, compare the different brands and types of machines on the market. They look at the quality of the products, but also want sufficient assurance of expert support and high-quality service in installation and commissioning, maintenance and repair. Machine builders therefore often work together with a strong local partner, supporting them in sales, installation and service. Thus MT Service is the permanent partner of TOS Varnsdorf for the Belgian market.

Otakar Ungerman is in charge at MT Service, which has long been TOS Varnsdorf's regular partner for the Belgian market.

The history of TOS Varnsdorf dates back to 1903, when a German entrepreneur began building machine tools in the Czech village of Varnsdorf. The name itself dates back to the period after World War II when TOS becomes a state-owned company specializing in the production of boring mills. The father of current managing director Jan Rydl succeeds in convincing the Czech authorities to privatize the company. This heralds a period of steady growth, as a result of which the manufacturer grows into a world player in the production of horizontal boring mills in various versions: floor type and table type.

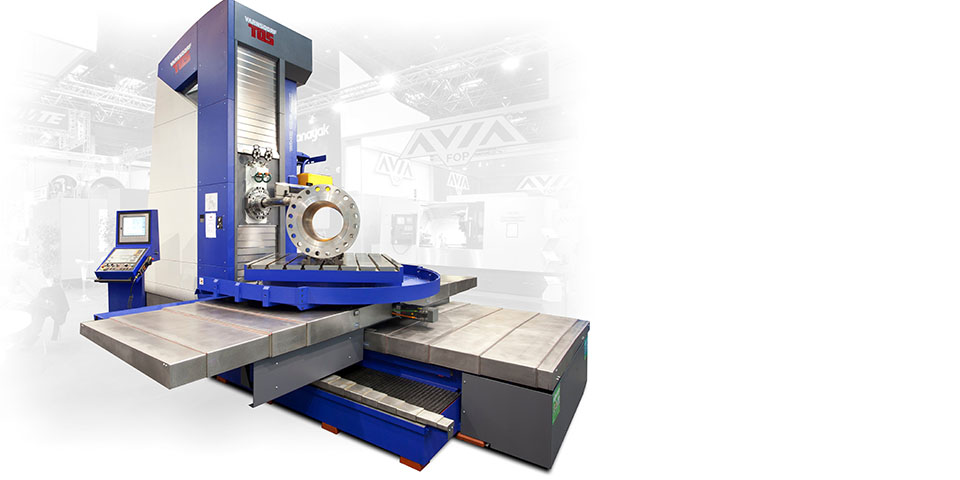

Innovation is the key word in everything the machine builder does. Witness to that is also this milling and drilling machine WHQ150.

Fast switching

As a family business, TOS can always move quickly to bring the right machines and solutions to the market. Almost all components, such as milling heads, spindles, tables ... are manufactured in-house. Innovation is the key word in everything they do. Witness to this are the WRD 130, 150 and 170 floor-type systems, the WVM 2600 T tabletop version, the WHQ 105 and WHN 15 horizontal milling and drilling machines and the WHT 110C and 130 C machining centers with integrated milling and drilling machines. "The compact horizontal machining center WHT 110C includes X, Y and Z axes of 3,000, 2,000 and 2,500 mm, respectively, with speeds of 25,000 or 40,000 mm/min and a rotary table with a load capacity of up to 6,000 kg. The bigger brother, WHT 130 C, is equipped with Y and Z axes of 5,000, 3,000 and 3,000 mm, respectively, with a speed of 25,000 or 36,000 mm/min and a turntable with a load capacity of up to 10,000 kg," explained Otakar Ungerman, manager of distributor MT Service. "These systems are equipped as standard with five fully controlled axes and CNC-controlled spindle rotations and can be expanded with automatic pallet and tool change, proprietary accessories, additional carousel tables ... They can also be combined with various control systems. HEIDENHAIN TNC 640, SINUMERIK 840D sl and FANUC 31i."

TOS Varnsdorf has become a world player in the field of horizontal boring mills and machining centers with integrated milling and drilling machines.

The perfect match

The quality of TOS Varnsdorf's machines is known worldwide, but the service also plays an important role. For the Belgian market, the machine builder found the perfect match with MT Service. "We are responsible for the sale of the metalworking machines and tools of quality brands that themselves do just that little bit more to make life easier for their end customers, like TOS Varnsdorf. Our employees also handle the commissioning of new machines and the relocation, removal and geometry of existing installations. They perform all repairs and do maintenance and overhaul of machine tools, whether purchased from us or not. Finally, we provide training in programming CNC controls of the Heidenhain, Fagor, Fanuc and Siemens brands," Ungerman explains. "Customers are becoming more and more demanding, machines and processes more complex. In addition, there is the far-reaching automation and digitalization. TOS Varnsdorf opts for standard lines with great modularity, simplifying production. Customers can, however, decide which bells and whistles they want to add. Today our cooperation is synonymous with quality in terms of product and service and we want to keep it that way in the future."