Gas springs from ACE simplify COVID-19 diagnosis

Especially during the corona pandemic, intensivists need rapid X-rays of the lungs of infected patients. Mobile X-ray equipment is one of the most effective tools in making the diagnosis. When Wuhan was hit by the first wave of infection, the Wandong company was able to provide X-ray equipment in record time, equipped with gas stretchers from ACE Stoßdämpfer.

Guest stretch springs for Wandong mobile X-ray equipment

A radical lockdown and the construction of completely new hospitals in just a few days. The images of Wuhan in the early 2020s are forever etched in our memories. Everything was pulled out to combat the corona crisis. There was very little time to treat patients with severe symptoms of COVID-19. Therefore, the criteria that doctors, nurses and medical equipment suppliers had to meet were extremely high. This was also true for Bejing Wandong Medical Technology Co. Ltd. a specialist in diagnostic imaging equipment known worldwide under the Wandong brand name. Thanks to intelligent production and service processes, the company managed to deliver large quantities of equipment in a short period of time. However, the urgently needed digital mobile X-ray equipment required additional help from the supplier, who had to be able to supply industrial gas springs quickly. Mobile X-ray digital radiography (DR) devices are an important technical tool for physicians. They are robust and the quality of the images is as good as that of fixed DR equipment. Even more important is their flexibility, as they allow medical personnel to view patients' lungs almost anywhere. At the same time, they release less radiation compared to previous solutions.

The deployment of mobile x-ray equipment in Wuhan

ACE convinces with short delivery times

For the purpose of further improving safety for the user of mobile solutions, Wandong had already explored the gas spring market before the pandemic and tested products from various manufacturers. The goal was to reduce operational risks when moving the X-ray arm of the device. Medical personnel must raise and precisely position this arm to reach a certain control position, which can vary depending on the patient's anatomy. Therefore, the quality and reliability of the industrial gas springs are very important to be able to keep the arm in place during X-ray taking. Even during the testing phase, ACE's gas springs proved to be the first choice. When the health crisis in Wuhan reached its peak and ACE was able to supply hundreds of high-quality units in a short period of time, Wandong was convinced that they had found the right supplier. Dr. Tian Xuefeng, director of STABILUS (Jiangsu) Co., Ltd, on behalf of ACE (part of the STABILUS Group) summarized the situation on the ground. "We made every effort to ensure that our products would reach the X-ray equipment manufacturers as soon as possible. During this severe epidemic, every minute and every second counts."

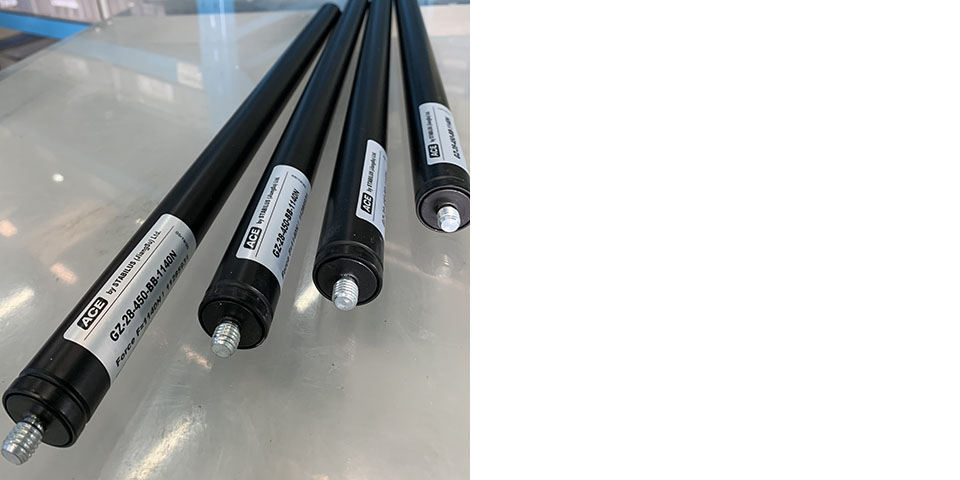

guest stretch springs from ACE

The chosen type GZ-28-450 guest rack springs have a positive effect on user-friendliness in several respects. They ensure that the X-ray arm remains in the desired position and, in addition, assist in raising, lowering and retracting the mechanism. In doing so, their operation is exactly the opposite of traditional gas pressure springs. The piston rod is located in the cylinder in an unloaded state. The gas pressure in the cylinder sucks the piston rod in. Constructors can choose from a diameter of 15 to 40 mm and forces of 50 N to 5,000 N for ACE's maintenance-free and ready-to-install gas extension springs. Models with a diameter of 28 mm, a maximum tensile force of 1,200 N and a stroke length of 450 mm are used in Wandong's mobile X-ray equipment. All gas springs from ACE have a hard-chromed piston rod and an integrated plain bearing, and therefore have a high service life. Another advantage: independent of the stroke length, the tensile force can still be adjusted via a valve.