Process optimization throughout the entire production process

The metalworking industry keeps a close eye on process costs. By improving the processes around tool use, production costs can be significantly reduced. The Hoffmann Group offers a wide range of benefits for controlling processes and supports customers along the entire process chain. This process optimization immediately forms one of the highlights at the TechniShow.

Streamlining processes and reducing process costs is one of the important themes of the fair, and the synergy between machine/software and tools is part of this. Under the motto "Always Better," the Hoffmann Group always adapts to changing market conditions and thus continuously introduces new products and services. To this end, it cooperates intensively with machine manufacturers, such as Mazak, Promas, Style and Dormac, as well as tool manufacturers and software houses, in order to always offer an appropriate solution. The catalogs of the Hoffmann Group, also called "The Orange Bible," contain more than 80,000 articles and the company has specialists in machining, measuring, personal protective equipment and factory equipment as well as C-article management.

Innovation at the TechniShow

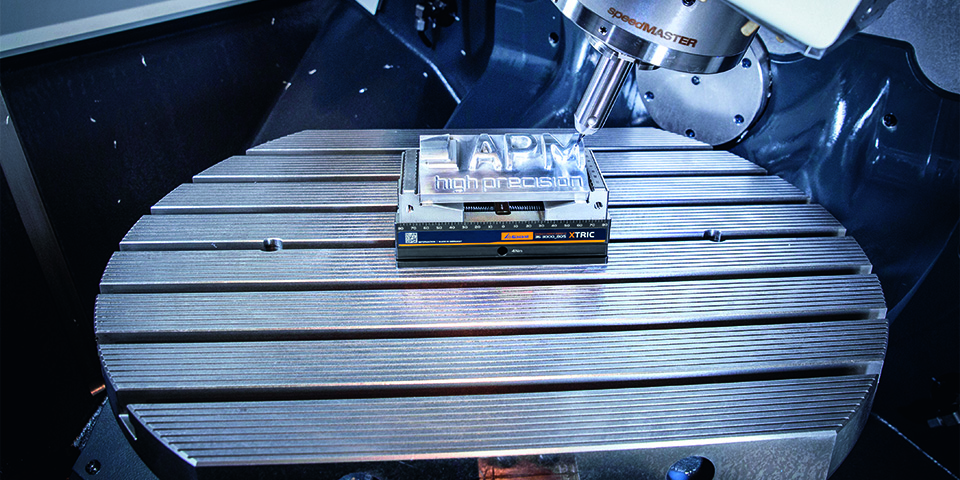

At the TechniShow, visitors will not only get an overview of the existing product range, but the Hoffmann Group will once again unpack a number of innovative solutions. "For example, we will present the Tool24 Smartline, PickOne and Locker for purchasing and consumption management, and the latest milling strategies will be featured during machining demonstrations with GARANT tools on a Hedelius Acura 65. There will also be a teaser of Connected Manufacturing, a software tool for planning, controlling and organizing production environments that will soon be on the market," explains product manager Marcel Schwarts. "Furthermore, visitors can learn about the Xtric centric machine clamp and the GARANT setting bench for quick and efficient setting of measuring tools. Visitors will also get an impression of the possibilities of the unique GridLine system for workshop equipment, which is characterized by ergonomics, efficiency and emotion (E³)."

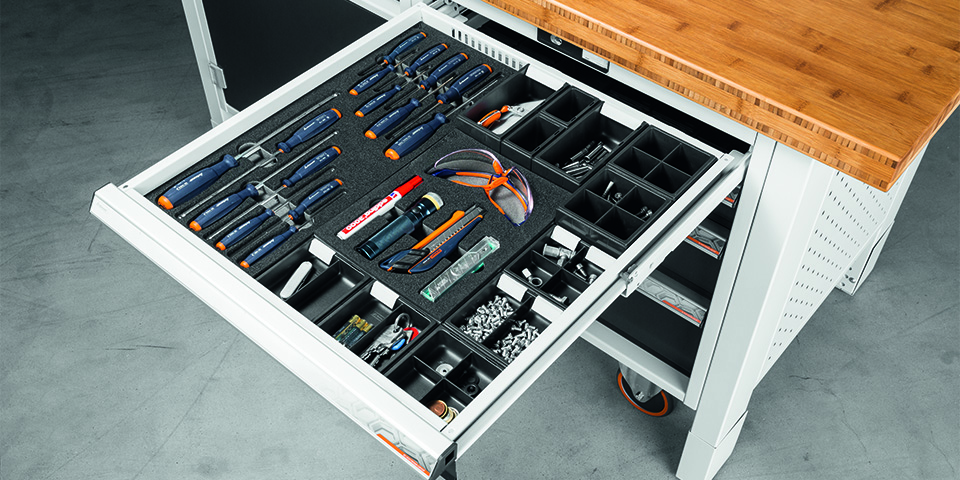

The unique GridLine system opens up a variety of possibilities for workplace design.

Process optimization as a highlight

The Hoffmann Group supports customers throughout the entire process chain, from work preparation, tool presetting and production to finishing and demonstrates methods for optimizing processes. This starts as early as purchasing, where through the GARANT Tool24 Smartline, PickOne and Locker downtimes due to shortage of parts can be avoided at all times. These article and tool dispensing systems are available in different versions - drawer cabinet, vertical cabinet or single-piece dispensing cabinet - and their modular design ensures maximum flexibility in set-up. With the simple purchasing platform Simple System, one can automate recurring processes, easily search for products and services at suppliers and quickly and easily handle inquiries and ordering processes.

Proper tools and strategy for application

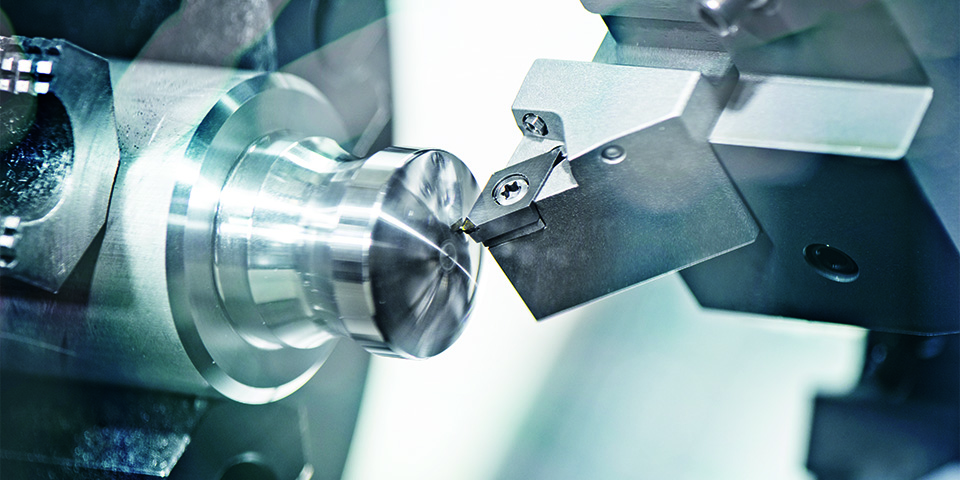

"With our ToolScout one can quickly and easily find the right tool for applications such as milling, drilling, turning, threading, measuring and testing. Here tools from GARANT and HOLEX as well as from other manufacturers such as Kennametal, Kyocera, Komet and many more are presented. The chosen tool can be saved as a favorite and easily ordered directly in the Hoffmann Group eShop," Schwarts continues. "Of course it is important to use the right tools, but choosing efficient production strategies also contributes to higher productivity. For example, proper CAD-CAM programming with trochoidal milling (Trochoidal Performance Cutting) can save up to 50% of time. Finally, maintaining the original quality of machining tools has its advantages. Therefore, customers can come to us for re-sharpening and re-preparation of their tools."

Tools must always be at their best. This is why customers can turn to the Hoffmann Group for re-sharpening and re-preparation of their tools.