Taking roughing operations to the next level

CNC workshops want to increase their chip volumes while reducing their lead times. Efficient machining strategies are the foundation for an economically viable CNC manufacturing environment. Roughing processes often have great potential for improvement, as they account for a significant proportion of a part's total production time. To make that possible, HEIDENHAIN has developed groundbreaking new features, Dynamic Efficiency solutions. Thanks to OCM (Optimized Contour Milling), innovative milling strategies can be implemented directly on the control for the most efficient machining.

In today's high mix, low volume production, the man at the machine is a crucial factor in the whole. After all, he has to make sure the pieces come off the machine right the first time to ensure profitability. For HEIDENHAIN it is therefore important to give him all the tools he needs to perform his job as efficiently as possible. The German specialist previously introduced interesting process optimizations that contribute to this. Active Chatter Control, for example, is an automatic vibration control that occurs directly through the controller. By automatically compensating for vibrations that can occur during heavy rough machining, marks on the workpiece and damage to the tool are avoided.

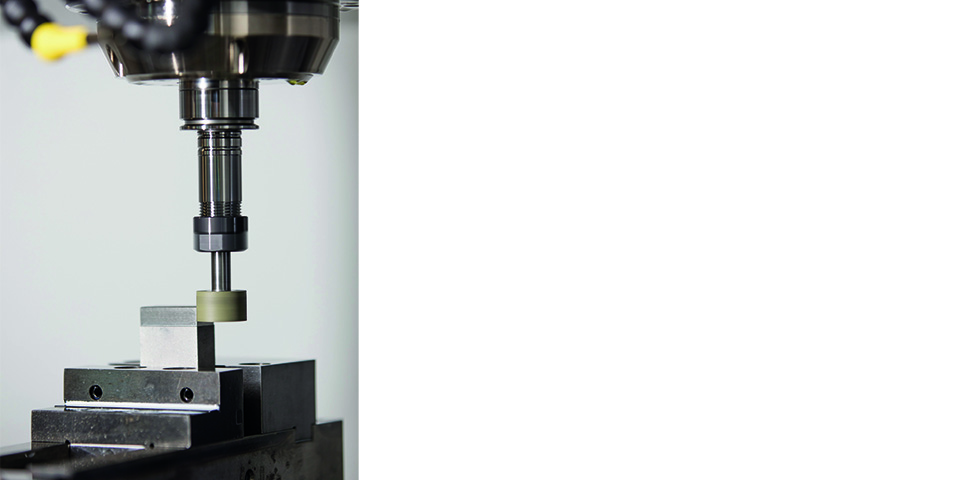

HEIDENHAIN control also allows grinding operations to be controlled to perfection for exceptional surface quality.

Productivity up with 66%

In 2020, particular attention will be paid to OCM, Optimized Contour Milling, a new option for the TNC 640, TNC 620 and TNC 320 controls that can reduce lead time by 66%. The premise behind this development is that due to the complexity of modern workpieces, CNC workshops are almost forced to invest in a CAD/CAM package. Olaf Van Der Taelen, Customer Value Engineer at HEIDENHAIN: "However, by working directly on the control one can perform optimizations in real time. With CAM, this is often impossible." Therefore, thanks to OCM, HEIDENHAIN offers the user the possibility to apply innovative milling strategies to any shape to be milled, whether it is a chamber, island or a combination of these shapes. OCM allows "trochoidal milling" or whirl milling to be applied significantly more widely. "Pass depth, chip thickness, work feed, the milling path ... is determined by the choice of tool and the material to be machined," Van Der Taelen knows. "Because the tool performs a whirl motion, a combination of straight-line and circular motion, manually programming the milling path becomes a difficult task. Whereas whirl milling was initially used only for milling slots, the control now ensures, via a number of new cycles, that OCM can be used in a simple way for any contour, both in roughing and finishing operations. The result? Thanks to OCM, one can choose a higher milling feed and achieve deeper chip removal, increasing productivity. This milling technique also significantly improves tool life."

Perfect finishing in one fixture

HEIDENHAIN's TNC 640 was already capable of milling and turning in a single fixture. Meanwhile, a third machining process has also been added to that list, grinding as a machining technique. By combining milling, turning and grinding, one can now deliver workpieces with exceptional surface quality in a single fixture. The new grinding functions can be applied to any contour on a milling machine. In addition, easy-to-use standard dressing cycles can level and correct the grinding tools in the machine tool. Thanks to the optimized tool management for each process, the user receives all possible support with both grinding and shaping of the grinding stone.