Flexible bending automation: as powerful as never before

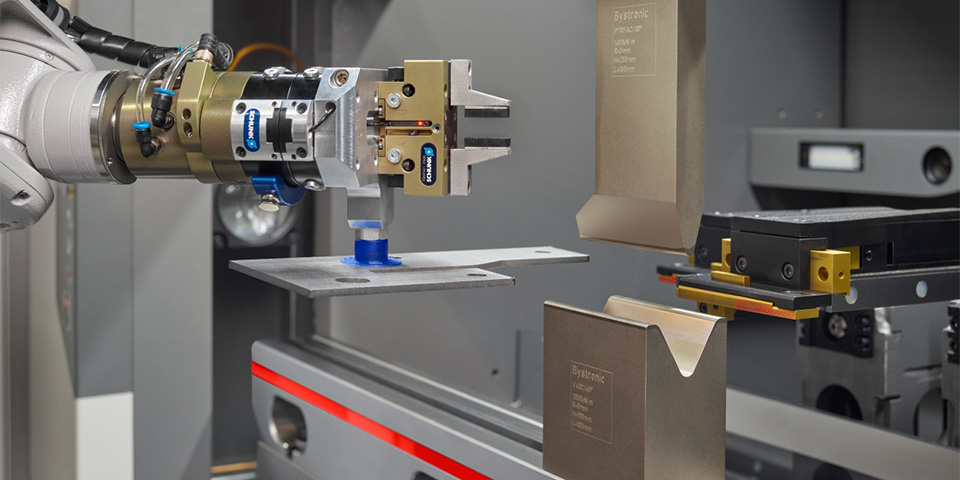

Automation on Demand: for a long time, sheet metal working did not know that. Bystronic has opened the door to this and, with the Mobile Bending Cell 80, is marketing a compact and powerful bending solution that allows both: automated and manual bending.

The Mobile Bending Cell 40 is a success story. The flexible bending automation solution was awarded the innovation prize in the "Forming Technology Cold/Hot" category at Blechexpo 2017 in Stuttgart. The combination of ultra-modern bending robotics and the compact press brake Xpert 40 with a press force of up to 40 tons fully convinced the jury of the trade magazines "MM Maschinen Markt" and "Blechnet" - and then also the customers. The high demand exceeded the wildest expectations.

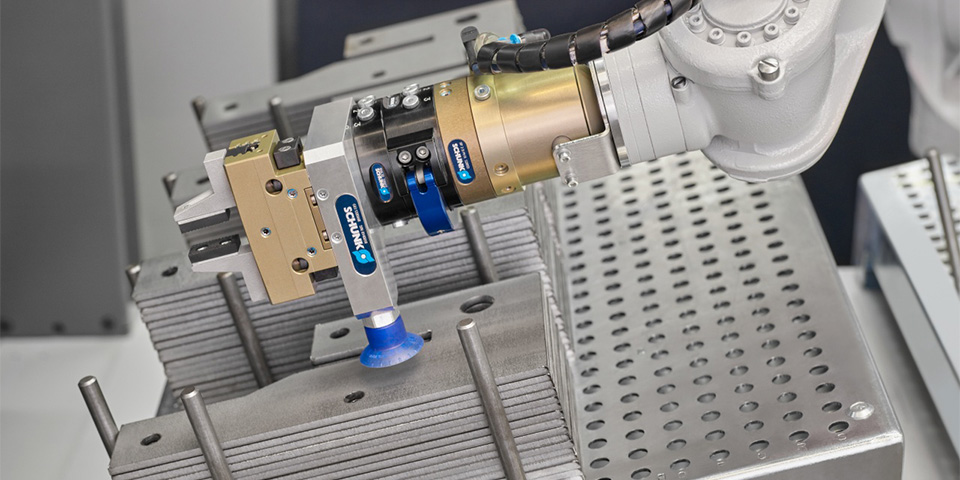

Now Bystronic is launching the big sister of this innovative automation solution: the twice as powerful Mobile Bending Cell 80. At a bending length of about 1.5 meters, it delivers a press force of up to 80 tons. This is made possible by the powerful press brake Xpert 80, also from Bystronic. Those who already have the manual press can easily upgrade it to the fully automatic Mobile Bending Cell. Here, the Mobile Bending Robot is simply driven to the Xpert and installed and adjusted within ten minutes.

Also producing at night

Modular design ensures maximum flexibility. The key word: Automation on Demand. Because just as easily as the robot can be connected to the press brake, it can also be removed again. Sheet metal workers no longer have to choose between manual and automated production. They now have both options at their disposal and can switch between them in an instant depending on the order book. Small batches or complex parts can be produced manually as before, large batches with the 6-axis Mobile Bending Robot.

There is an increasing need for flexibility today, as bending parts are increasingly produced in a variety of shapes, sizes and quantities. And it always remains necessary to produce the parts as quickly and cost-effectively as possible. The Mobile Bending Cell takes all of this into account. The use of the robot increases efficiency while relieving operators. Moreover, production can also take place at night without any problem. Indeed, once the bending orders are programmed, production proceeds without interruption.

Intuitive user interface

Intuitive user interface

Offline programming of bending jobs with the Robot Manager software and importing data into the ByVision Bending user interface are very easy and intuitive to perform. Basic knowledge is not required. "The software is an important USP of our Mobile Bending Cell," said Benedikt Kreisel, product manager for Bending Automation at Bystronic. "Although the competition now also provides mobile automated bending solutions, our combination of a simple user interface and maximum precision is still unique."

Because of its real-time compensation systems, the manual press brake Xpert is distinguished by a high degree of accuracy. Says Kreisel, "However, it is true that the probability of errors increases if an operator works on several machines simultaneously for eight hours." This is not true of the robot. Thus, thanks to automation, repeat accuracy can be further optimized. Process reliability increases even further with the optional conveyor belt. Because it operates even more stably than the bending part conveyor, it ensures that the bent parts remain undamaged during discharge.

Easy entry into automation

The Mobile Bending Cell 80 offers an easy entry into automation, especially for medium-sized operators with limited space. After all, the bending solution has a space requirement of only about five square meters (Xpert 80 about 3.5 m², Mobile Bending Robot about 1.8 m²). In comparison, a bending cell with a fixed robot is easily ten times larger.

Like its little sister, the Mobile Bending Cell 80 may become a success story. "For a long time, no one believed that a press brake could be operated by a mobile robot, that hardly any time would be lost in the adjustment process and that, at the same time, precision would increase," said Benedikt Kreisel. Bystronic, however, proves otherwise. It is indeed possible, even with a press force of up to 80 tons.