3D printers: sustainable manufacturing process for heat-resistant materials

Heat-resistant materials are difficult to form with conventional machining technology. This is due to the presence of the nickel alloy Inconel®, which can withstand temperatures of up to 1,000 °C. At the last EMO, TRUMPF showed the answer to this challenge. Thanks to 3D printing, Inconel® pieces faster, cheaper and produced with higher quality.

3D printers use only the amount of powder needed to make the piece. Unlike traditional machining methods such as turning and milling where material is removed. In addition, virtually no manual post-processing will be required, significantly reducing tooling costs. Moreover, 3D printing will guarantee high quality because it becomes so easy to create complex geometries.

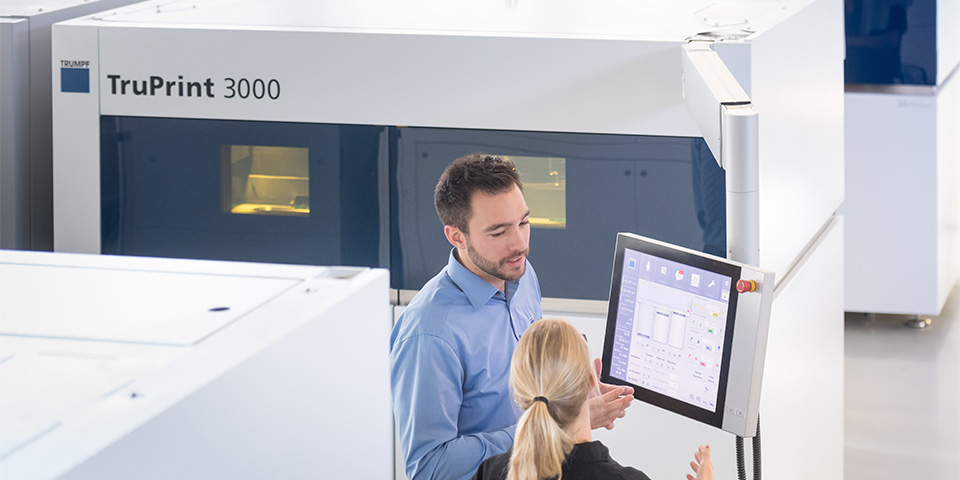

TRUMPF's TruPrint 3000 3D printer is the perfect machines for making components for power generation. (Image: Martin Stollberg)

Challenges of heat-resistant materials

Heat-resistant materials play a key role in many industries, including aerospace and energy. However, machining Inconel is difficult and costly because the tools will wear out quickly. This also has its impact on quality in certain cases, when the wear of the cutting tool is not detected in time. Thus, too much material is lost. Typical pieces in Inconel, such as turbine blades and impellers of gas compressors, are also often complex. Operators sometimes have to mill away up to 80% of the raw material to get the desired shape. Given a cost of 100 euros per kg, this creates a significant bill.

Fast production, sustainable use of raw materials

The TruPrint 3000 3D printer that TRUMPF presented at EMO is the perfect choice for applications with Inconel®. With its 40 x 30 cm chamber, the TruPrint 3000 can produce multiple pieces simultaneously. The system also offers solutions for automated quality control such as powder bed and melt pool monitoring. Two examples showed why TRUMPF has the perfect answer to the challenges of heat-resistant materials. The first was a 3D printed impeller for a gas compressor. This piece is finding its way into drones for mail delivery, model airplanes and small turbines. "It shows perfectly how we can exploit the strengths of 3D printing," says Andreas Margolf, project manager at TRUMPF Additive Manufacturing. "It normally takes eight days to mill the piece out of a block of Inconel. In contrast, the TruPrint 3000 3D printer can build three impellers simultaneously on the printing platform. Each piece is ready in four days, including post-processing. Similarly, only 20% of material is lost, especially in post-processing milling. 3D measurements have shown that the quality is also as high as the original."

TRUMPF was commissioned by Toolcraft to produce an intake vane used in aircraft engines. Total cost savings: 20%. (Image: Claus Morgenstern)

Lower costs and short delivery times

A second showcase at the booth at EMO was an intake vane ordered by Toolcraft. The vanes direct air intake and exhaust gases through the engine. They consist of sixteen curved vanes built around a common shaft. Because of the complex geometry, it takes 15 hours to remove the material. The operators have to spend a lot of time programming to ensure that the blades are produced correctly. The piece passes through the milling machine three times before it reaches its final shape, removing 85% from the material. 3D printing with TRUMPF's TruPrint 3000 system is significantly more efficient. Print time per piece is reduced to six hours, with only minimal milling for finishing. The lower tooling and material costs bring down the cost of the piece by 20%. Stefan Auernhamm of Toolcraft sees particular potential for 3D printing in spare parts and small batches. "Regarding hard-to-machine materials, classically machined spare parts are becoming increasingly expensive. In contrast, the cost price of 3D printed pieces continues to fall. Another advantage is that we can deliver the finished pieces faster, which is a decision factor for many customers." With 3D printing, the design of blades can be optimized even further. For example, one could start using hollow structures to further increase the cooling effect.