This new sawing machine is faster and, above all, more accurate

Sawing machines, especially those from top brands like Behringer, tend to last forever. The one at Westerhof B.V. in Denekamp was no exception. But after more than thirty years there was a need for a new machine and the big question was of course: which one? Because of the good experiences with the brand, Westerhof quickly ended up at machine supplier Promatt. They knew what to do and delivered a semi-automatic sawing machine, of course of the Behringer brand.

Westerhof's history dates back to 1964 when Mr. B.J.J. Westerhof started performing construction work. Under the inspiring leadership of two generations, the company has developed in the following decades into an extremely versatile solution provider in the field of technical solutions and the design and production of custom-built machines. To this end, Westerhof has various in-house competencies, including not only design, engineering, machining and construction work, but also maintenance and after-sales service. This makes Westerhof a versatile, solution-oriented total partner for a wide range of clients.

Broader scope

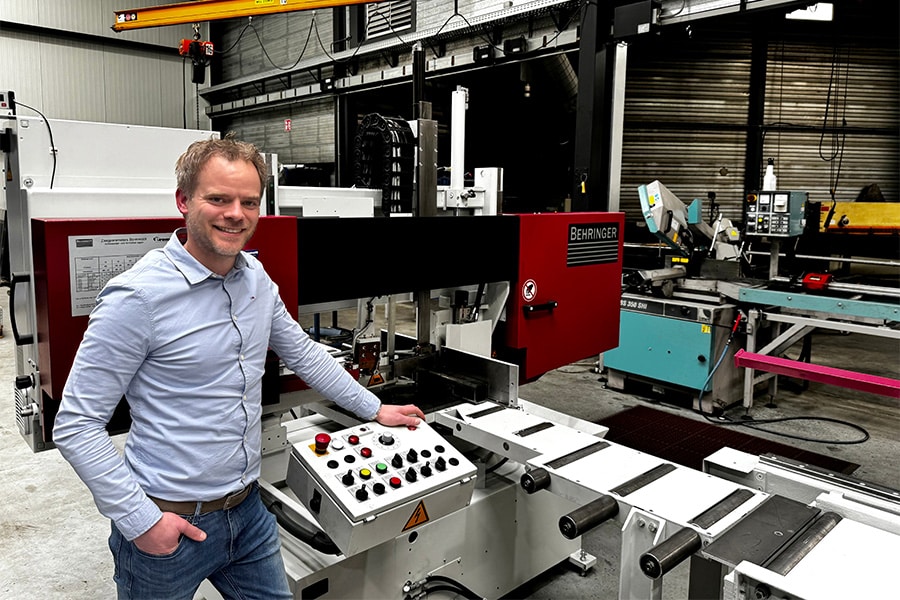

"Among other things, we supply solutions for the automotive sector including production lines for tire manufacturers such as Michelin and Vredestein," says Mark Waanders, manager of quality & innovation. "But we are also active for the defense industry, the pet food sector and the semiconductor world. Especially for demanding defense and semiconductor assignments, we also have a clean room, which allows us to deliver precise products with the required degree of cleanliness. Besides building new machines and (production) systems, we are also active in the field of overhaul and maintenance, allowing us to bring old machines back to their original 'new-condition' or even better!"

Knowledge partner

To be an experienced and expert supplier and knowledge partner for customers in various sectors from design to delivery, Westerhof in Denekamp has a flexible organization that currently employs some 80 people. "We do 'Built2Print' jobs where the customer provides the drawings, but we also have a powerful engineering department," says Waanders. "This develops customized solutions based on customer requests whose components are produced in our factory and then assembled and tested in the assembly department. We are currently preparing to build a new hall that will soon give us even greater assembly/assembly capabilities. This is necessary because the machines and constructions we build are becoming larger and more complex. In the production department, we have a multitude of production resources including CNC turning and milling machines with which we can perform all machining operations. We also build structures for which we have in-house capabilities such as welding, drilling and tapping."

Sawing flexibility

"We have raw material delivered cut to size as much as possible," Waanders introduces the topic of the new sawing machine. "But for flexibility it is necessary to have our own stable and accurate sawing machine. However, the Behringer band saw machine we were using before that had been there for several decades, and mechanical wear in particular meant that it had lost accuracy. We contacted Promatt to have a chat about a new one."

Behringer semi-automatic

"We have obviously known Westerhof for years, so when they came to us with the question about replacing the sawing machine, we had a great solution in store for them right away," says Marco Toebes, director of Promatt Netherlands in Haaksbergen. "We had a demo machine on hand that met their requirements perfectly, namely a semi-automatic Behringer HBE 320-523G. This is a universal band saw for material up to 520 mm wide and 320 mm high. The saw can be rotated for double-sided mitre cuts. In this area in particular, the concept of this new machine is different from that of the previous old machine. On the HBE 320-523G, Bahco bi-metal band saws are used where micro-lubrication by means of an oil mist ensures efficient and precise machining with a long service life of the saw. The machine frame is primarily cast iron which provides a stable and accurate machine that will serve Westerhof well for decades to come."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Promatt.

Contact opnemen

Contact opnemen