Third edition demo days another great success

By now we can safely speak of a tradition. Last October 3 and 4, Haaksbergen was once again the technical epicenter of the Netherlands for a while. Promatt held its third edition of the now famous DemoDagen. Two days packed with demonstrations of machines for various applications, news, promotions, conviviality and above all the unadulterated hospitality of Twente. While enjoying a snack and a drink, visitors could obtain information from no fewer than fifteen different manufacturers of machines and tools. Innovation was again at the center of this edition.

Big news at the DemoDagen: the new partnership with Spontan from Remscheid was shown in the form of the HRS-315, the 'Hochleistung Rohr Säge'. A very impressive machine with which tubes can be cut fully automatically. We speak with Peter Jackisch, a member of Spontan's management team.

Peter Jackisch at the Spontan HRS-315.

"We have been in contact with Promatt for a year and we fit well together. Our first meeting was at the trade fair in Düsseldorf and there it quickly became clear that we speak the same language. Promatt did not yet have a sawing machine for pipes in its program. The machine shown here was developed completely in-house, the automation technology comes from our own kitchen. That appealed greatly to Promatt. The saw drive, clamping technology, length stop technology, control cabinet and even the software are all in-house developments. That means we also have the expertise to provide service down to the smallest details. The software and the machine enter into a perfect marriage, because the software belongs to the machine," Jackisch outlines. The HRS-315 integrates plug-and-play within any workshop. "Customization is also possible," concludes Jackisch.

Perfect positioning is half the battle

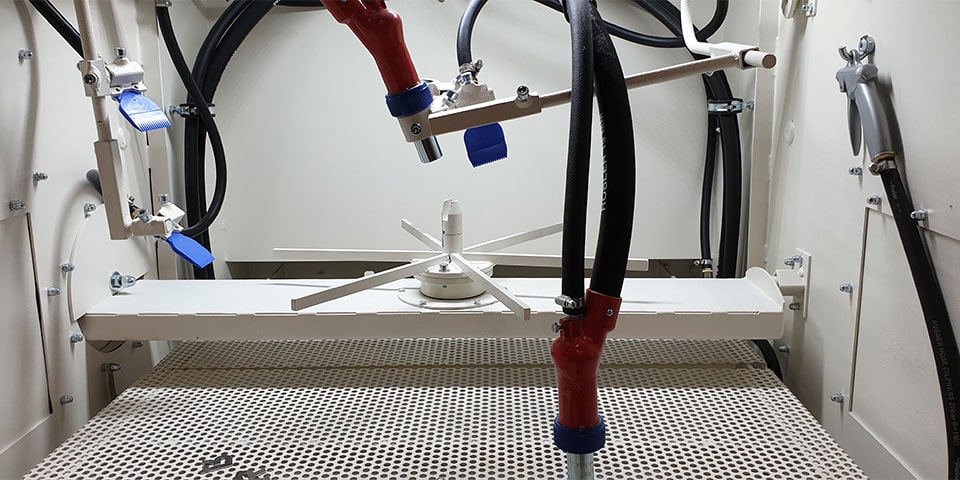

Director and owner of Position Automation, Jan Ballast, showed how perfect material positioning can be achieved with the machines they produce.

Jan Ballast of Position Automation.

"We build machines to customer specifications. The material is positioned, drilled, punched, cut or sawed. Then clean blown and/or brushed. All our machines are proprietary designs based on existing semi-automatic machines. We combine these into fully automatic production lines," Ballast said. Position Automatisering and Promatt have known each other for fifteen years, with increasingly intensive cooperation in recent years. Ballast observes that the demand for fully automated solutions is increasing again: "There is money again for this kind of solutions and it is more difficult to get personnel. This reinforces each other. The Enter-based company builds machines that range from simple to highly advanced. "We only do business with manufacturers of top-quality semi-automatic machines," Ballast says. "That's why our machines can be considered part of the A segment, and that's exactly why Promatt does business with us."

Promatt always manages to create an excellent balance between information and conviviality. Hospitality is written with a capital G in Haaksbergen.

A technical trinity

On behalf of Rössler, Erwin Verbruggen speaks to us about the Partners for Steel partnership.

Erwin Verbruggen of Rössler literally and figuratively stands for Partners for Steel.

"Partners for Steel consists of Rössler, Behringer and Vernet Behringer. The strength of the cooperation lies in providing total solutions, where everything is perfectly matched. An example: a customer has a rusty tube that needs to be machined. Rössler first comes into the picture for blasting, with the roller conveyor blast machine. With 3,200 kg of abrasive per minute and at least four turbines, the profile is blasted perfectly clean. Then the profile can proceed to Vernet's sawing/drilling unit or, if only sawing is involved, to Behringer's sawing unit." The partnership is a logical consequence of the fact that the three companies are on the same level in terms of capacity and quality. Verbruggen continues, "Also the communication between the disciplines is perfect, we speak the same language. Everything comes from the same hand and ensures a piece of process optimization. This working method fits completely within Promatt's philosophy."

May we introduce?

Our host during the DemoDagen was Henk van der Meulen, a new star in the firmament in Haaksbergen. Van der Meulen has been working for Promatt since September 1 and will be deployed as a "flying goalie.

Henk van der Meulen is a techie at heart.

"My background is technical services, I did that for ten years. At Promatt I'm deployed broadly, good to get a feel for all branches of this company. That means you'll encounter me in the sales department and as a technical advisor, both inside and outside," Van der Meulen explains. "I am a techie at heart and have a technical education." Promatt has once again shown why it deserves its leading position in the industry. We look forward to the next edition of the DemoDagen!