Complex products and reduced downtime thanks to dedicated software

Being able to switch easily and quickly from one machine to another with an instantly working program. It is one of the advantages Peter van de Riet lists when Visietech uses the TopSolid software. "We make more complex products and have less downtime."

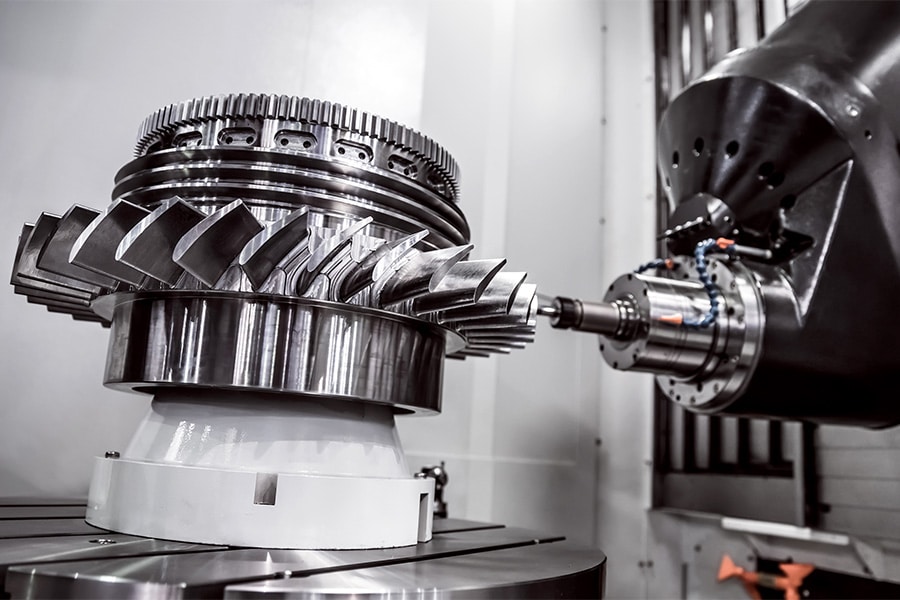

Within the Andra Tech Group, Visietech is a specialist for milling-turning and fully assembled products. The focus is on serving customers in mechanical engineering, aerospace, packaging, mining, automotive and agriculture. Central to the manufacture of products are the Nakamura Tome machines. As part of continuous improvement, Visietech has made a number of changes, according to CAD/CAM programmer Peter van de Riet.

Switching to TopSolid

Van de Riet, project manager at the implementation: "There were several reasons to switch to TopSolid. In a short period of time, Visietech started making much more complex products, which also required a sprint in development. Earlier machine programming consisted partly of copy and paste. We changed that."

Offline programming during production

Thanks to the new software, Visietech can now make more complex products and there is less downtime. "We achieve the latter by programming offline while the machines just keep running. In terms of efficiency, you don't really want to program on the lathe itself."

Change in work processes

Implementing software, especially if the old software has been in use for a while, means a change in work processes. "This is why we took plenty of time to implement TopSolid. The goal was and is to be able to make adjustments ourselves if necessary. You can only do that if you know exactly how the software works. So if it is necessary to draw up all the tools, we do that ourselves."

Tool library and checks

The rollout of the TopSolid software was important for the steps Visietech wanted to take, but adoption alone is not enough, Van de Riet says: "There are steps to be taken after that, too. For example, we put a lot of energy into setting up the tool library with the tools available here." Almost everyone was working with their own machine and tooling before the rollout.

"We put our heads together and worked toward a standard design." Van de Riet took the lead in the follow-up steps himself. "Step by step with checks. That listens pretty closely and therefore results in an immediately working program."

Huge benefits

Although Visietech has a good reputation and holds both ISO9001 and AS9100D certifications, quality, price and speed are equally important, the project manager states. "A program from TopSolid now goes directly to the machine. That works really fast. The cutting data are all in the system, too. The reason? An employee can never know everything. Our machining conditions are now always optimal." The main gain according to Van de Riet: "Producing at lower costs, less programming time, decreased tooling costs and longer tool life. "Even if there is someone behind the lathe with less experience, we can make more complex products. The result is that we can serve old and new customers with more variety than before."

Andra Tech Group

The experiences with the CAD/CAM software have now also led more companies within the Andra Tech Group to seriously consider TopSolid for the programming of CNC turning machines within their organization. This choice is based on the clear advantages achieved by Visionch, but also on the independent choice that subsidiary DKH Metalworking has now made for TopSolid.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met TOPSOLID Netherlands B.V..

Contact opnemen

Contact opnemen