Integration of press brakes highest priority

Developments in the field of press brakes are in the areas of electrification, automation and the increasing role of software. The latter two things streamline the entire production process and reduce the need for well-trained personnel at the machine. The right software and integration of machines also reduce the risk of errors and make the process more efficient.

As in many industries, companies in sheet metal working are suffering from the disappearance of knowledge. Good machine operators are becoming rarer and rarer, and the demand for a solution to produce high-quality products - despite declining know-how - is growing louder. Machine manufacturers are responding by developing various solutions.

Intelligent machines

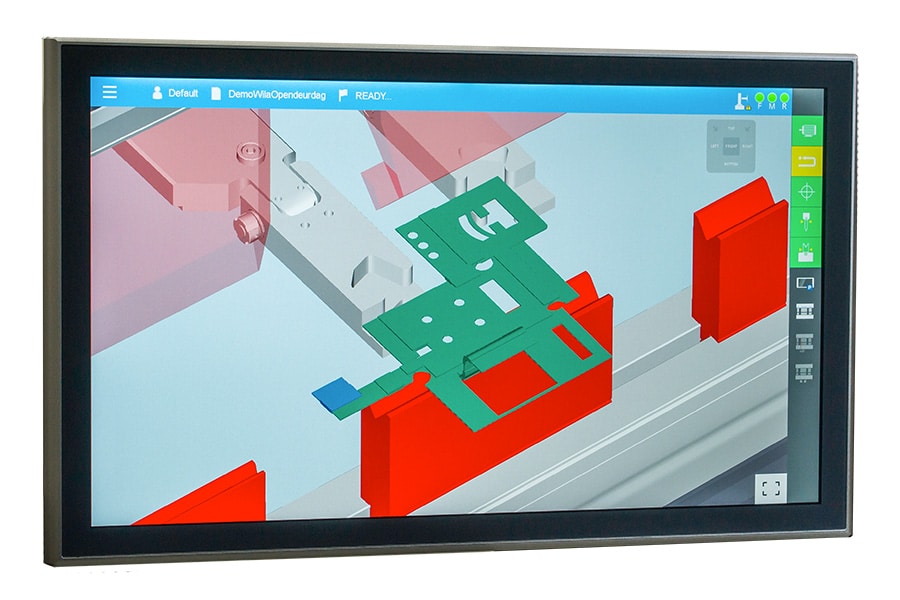

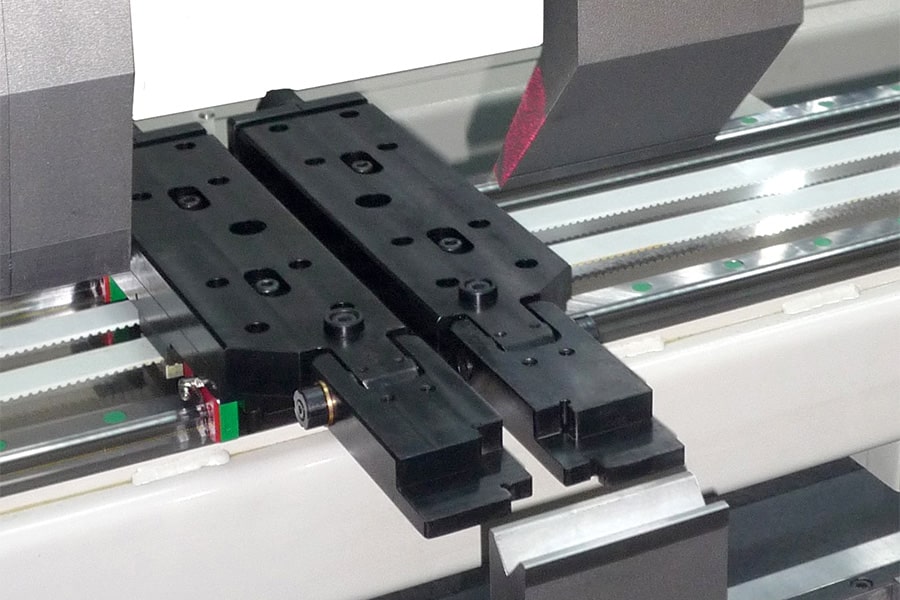

One of these solutions lies in making machines more intelligent. This is reflected, among other things, in the controls that guide the operator -like a wizard- through the entire setting process. The operator enters the specific data belonging to the product he needs to make; the machine then determines itself the settings needed to make the right product in the desired quality. Including the required tools. This process can be further simplified by incorporating all data normally entered at the machine into a barcode or QR code. As a result, the operator only has to scan the code and the machine takes care of the rest. This is not only a good solution to the knowledge problem, but also makes it possible to fully employ new employees at very short notice. Especially when employee turnover in companies is high, this development contributes to the continuity of the company.

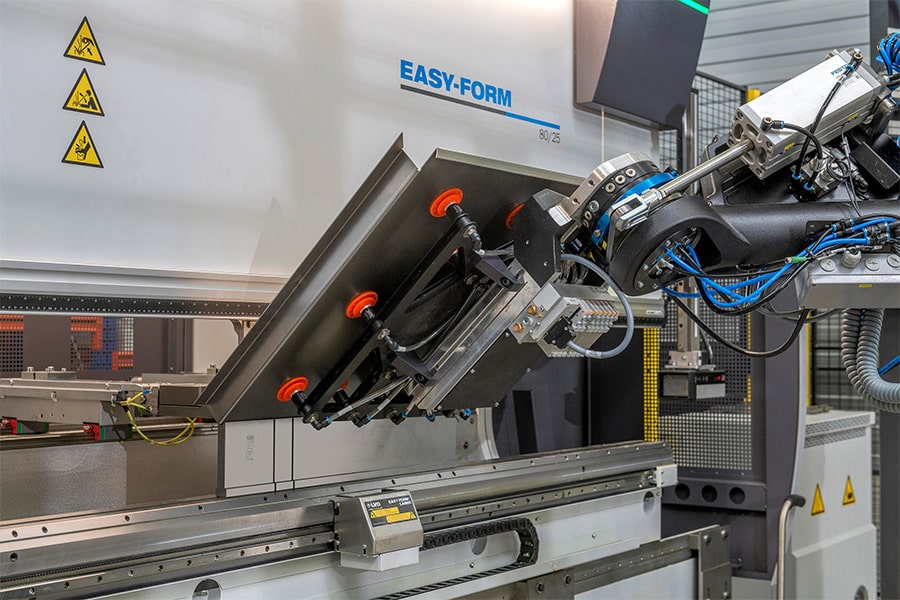

Automation

Precisely because press brakes are in many cases part of a series of operations, automation plays an increasingly important role. Fixed, complex robots that support the loading and unloading of the machines are often only used for larger series. For smaller series, they are easily too expensive. However, the development of mobile robots and cobots that can be used multifunctionally is also continuing and may in the future contribute to this type of process in handling the smaller and lighter products. Following on from automation, there are also significant developments in the area of software. This has to do with the increasing interest in integration. Users of press brakes would prefer to link all machines in a specific production process by software. This starts with a 2D or (usually) a 3D drawing that the offline software automatically converts into the appropriate machine programs for all operations. With offline programming the program is often written from the office environment which eliminates the programming work on the machine. The knowledge is then not needed at the machine and the people with knowledge can use it efficiently in an ergonomic environment. Machine manufacturers and specialized software developers who write their own software can in this way maximize the need for integration. Partly because it can also include planning so that products can be delivered "just-in-time".

From hydraulic to electric

A completely different trend can be observed in the drive of press brakes. The really "big boys" cannot escape the use of a hydraulic drive system. Only this technology can provide the required power density. With smaller press brakes -up to about 130 tons-, however, electric drives play an increasingly important role. An all-electric bench is quite expensive, but the hybrid and "mild" hybrid variants cleverly combine the advantages of the high force density of hydraulics with the speed and efficiency of the E variant. Here, the electric part provides, among other things, energy savings of up to 60%, oil savings of up to 60% and speed improvements that can reach 40%. Also, slightly higher accuracy can often be achieved with these machines.

Retrofit

In the context of sustainability, terms such as circularity, recycling and reuse often come up. This is also possible with press brakes. Some suppliers provide a retrofit after many years of use, giving an existing machine an almost new life. The retrofit then often involves replacing or updating the controls, giving the bench new capabilities. Restraints, of course, remain because the original frame remains in place. As far as this is concerned, nothing changes about the mechanical characteristics and the way of loading and unloading. With this, although the machines are slower than the more modern variants, much advantage is gained with a limited investment. The user also avoids the premature scrapping of a good machine frame which is a good thing in the context of material transition.

Plenty of developments

In short, plenty of developments to keep an eye on. Especially since automation and software modifications can often be implemented in existing machines. Without excessive investments, companies can improve their processes and make them more efficient.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met LVD Company.

Contact opnemen

Contact opnemen