Removing metal slag efficiently

At many companies, removing slag on metal is still a manual task. Nevertheless, more and more are turning to machine-based, automated processing. With the recent introduction of the Hammerhead, Timesavers has the solution in hand for processing plasma and flame cut parts. Using this aggregate, residual material can be removed even smarter. At Blechexpo, Timesavers will demonstrate the 22 and 42 series machines with Hammerhead aggregate. There are also the 32 series WRBW, the12 series WB for small parts and the 10 series (Manual Grinder) for machining small batches.

Originating eighty years ago as a repair store for woodworking machinery, today Timesavers has become an industry leader in the manufacture of machines for grinding, metal sheet deburring, finishing and precision grinding. The company has sold more than 50,000 machines for production facilities worldwide, many of which are still in operation today. Meanwhile, the R&D department remains heavily committed to innovation, such as brush machines with Hammerhead aggregate.

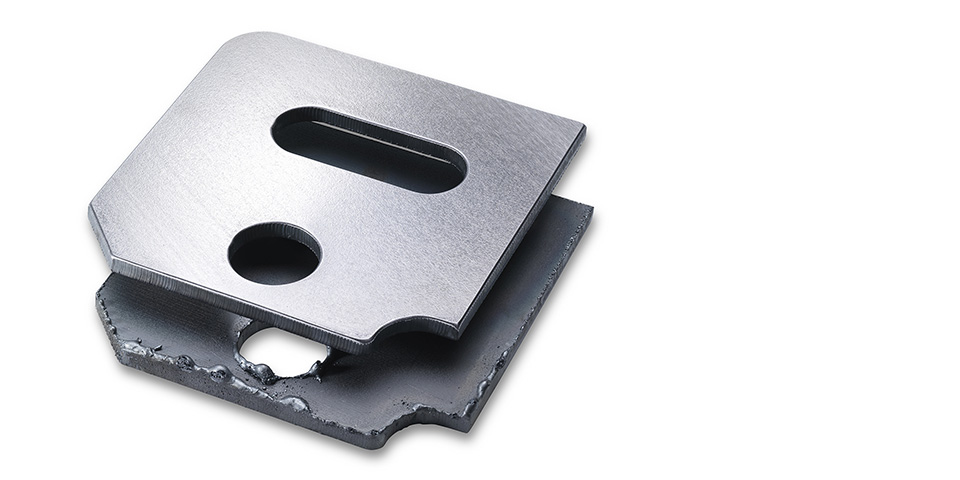

Make your own comparison between a non-machined piece and a workpiece where the metal slag was removed with a Timesavers machine.

22 series

For companies looking for smart automation for removing slag from metal, the 22 series machine with Hammerhead aggregate is an effective solution. The aggregate consists of a shaft with pins, which hammers off the slag. On one side of the machine, the operator slides the steel in and on the other side it comes out clean. It is very simple, but of unprecedented value to many companies. This machine increases efficiency and speed on the shop floor, but finaly also contributes to reduced absenteeism among staff. No more fine dust is released. Metal cleaning is more accessible, pleasant and prevalent. When manually removing metal slag, employees are more at risk of injury due to the vibrations in their hands.

32 and 42 series

The Hammerhead is also available in a 42 or 32 series machine in combination with one or more sanding belt units and a rotary brush unit for even deburring and rounding of a wide variety of products. "At Blechexpo, the international trade fair for sheet metal working, we are showing the 42 series HWRB rotary brush machine with Hammerhead. This system guarantees high-quality results in various applications, such as deburring, edge rounding to a radius of 2 mm, laser oxide and heavy slag removal," explains Bo de Muijnck, responsible for E-commerce marketing and communications at Timesavers. "In addition, we are presenting our increasingly popular 22 series H, equipped with the Hammerhead for heavy slag removal and the versatile 42 series WWRBW rotary brush machine, which provides optimal deburring, uniform edge rounding up to 2 mm radius, as well as finishing and laser oxide removal capability." Timesavers is also highlighting the 32 series WRBW rotary brush machine, a more economical solution for deburring, rounding, finishing and laser oxide removal. This machine will be equipped with a new option, available for both the 32 and 42 series: the automatic brush set-up, an optical system that continuously measures the brush length and automatically adjusts the brush to the user's exact requirements. This eliminates the need for manual calibration.

For companies looking for smart automation for removing slag from metal, the 22 series machine with Hammerhead aggregate is an effective solution.

10 and 12 series

In addition to the 22, 32 and 42 series machines, Timesavers will demonstrate at Blechexpo the 12 series WB, which received a new design and is ideally suited for deburring and finishing small parts. Finally, visitors can perform their own tests on the reliable 10 series Manual Grinder, a cost-effective machine for deburring, edge rounding and finishing small batches.

BLECHEXPO: HALL 1 - BOOTH 1803