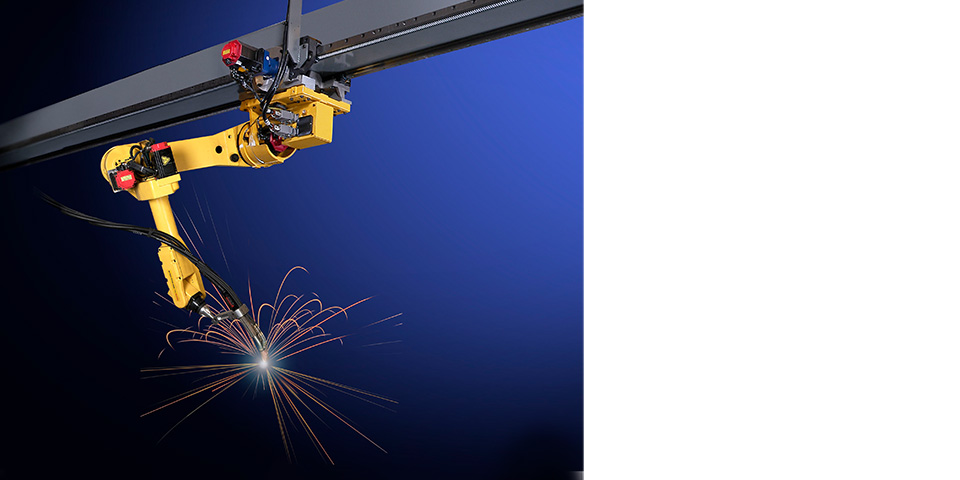

No shortage of good welding robots

Welders have become a scarce commodity. Fortunately, FANUC has no shortage of good welding robots. The ARC Mate series is specifically designed for arc welding applications. Moreover, FANUC offers a range of accessories and intelligent features focused on welding so it can offer customer-specific welding robots for any welding solution.

"It is no easy task for metalworkers to find good welders. Welding robots are then a valid alternative that also achieve the same welding quality and productivity under all conditions," opens Paul Ribus, managing director of FANUC Benelux. The welding robots in the ARC Mate series are the result of years of experience in robotics and welding. With a payload of up to 20 kg and a working range of more than 3 m, this series is suitable for very many applications: arc welding, laser welding, as well as cutting. The slim design and small footprint of the ARC Mate series is completely focused on the welding process. For example, freedom of movement was taken into account by equipping the robot with a hollow wrist for the internal feeding of the welding wire, it is also possible to place the wire feeder on the shoulder of the welding robot ensuring a more stable wire feed. "One of the many strengths of our welding robots is that our interfaces are built as open as possible," Ribus continued. "That makes us welding source-independent. Any supplier can connect their technology to it." This way, the user can really put together the welding robot according to his needs and wishes. Just that makes the difference in efficient in welding applications.

Range of accessories and intelligent features

To further tailor the welding robot to the customer's product and production process, FANUC offers a range of accessories and intelligent features. Ribus lists some of them: "Welding seam tracking systems, for example, which can also be integrated into the communication for perfect feedback. Think also of one- or two-axis positioners to weld the entire workpiece in one smooth motion or the integration of vision. Also equipping the welding robot with an external axis, for example a robot track for welding very large parts, is among the flexible options."

Offline programming thanks to ROBOGUIDE

Specifically for the welding process, FANUC has developed the WeldPro program in its 3D robot simulation software. "In WeldPro, you can completely simulate a robot welding process in a 3D environment allowing you to optimize the welding process and reduce cycle times. Because you create the entire welding program offline without the robot being at a standstill, you save a lot of time and costs," Ribus explained.

Production monitoring and analysis

FANUC has all the tools to monitor and optimize production. "Intelligence is the indispensable link in the evolution towards Industry 4.0 and the Internet of Things. Production monitoring and analysis enables real-time tracking of every production machine and collects all production results. With trend dashboards and by analyzing this statistical data, productivity is optimized," Ribus adds. In addition, FANUC Benelux introduces ZDT (Zero Down Time) which reduces maintenance costs and results in optimization of maintenance personnel by centrally managing maintenance statuses of production machines.